Steel ball positioning and fastening type die handle for machining internal and external threads and using method thereof

A technology of internal and external threads and fastening, which is applied in the direction of metal processing equipment, manufacturing tools, thread cutting devices, etc., can solve the problems of low loading and unloading efficiency, complex equipment structure, low processing efficiency, etc., and achieves convenient loading and unloading, obvious economic benefits, and convenient The effect of debris and dirt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings, but the present invention is not limited thereto.

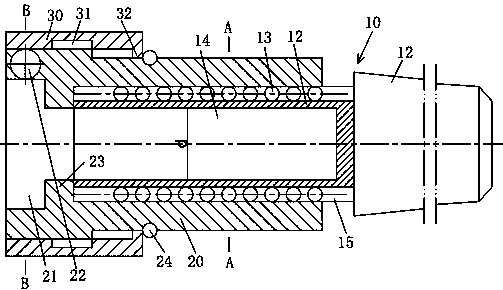

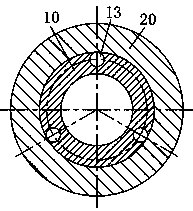

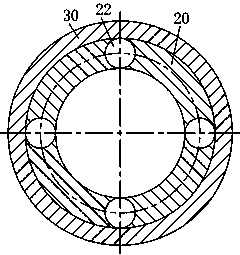

[0026] refer to Figure 1 to Figure 6

[0027] A steel ball positioning fastening type die holder for processing internal and external threads, including a cone mandrel 10, a rolling slip sleeve 20 is sleeved on the shaft 11 at one end of the cone mandrel, so that the rolling slip sleeve can Pulls straight out for easy removal of crumbs and dirt. The other end of the cone mandrel has a cone 12 connected to the taper hole of the lathe tail center sleeve, and one end surface of the rolling slip sleeve is provided with a mounting hole 21, which can be used to install the circular die and fix The tap holder 40 of the tap is used to process both external and internal threads without disassembly. The side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com