Device and method for filling and unloading liquid ammonia

A liquid ammonia, loading and unloading arm technology, applied in the container filling method, the container discharge method, the equipment loaded into the pressure vessel, etc., can solve the problems of simple function of the application device, inefficient safety monitoring, complicated operation process, etc. Comprehensive, effective, simple device and method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

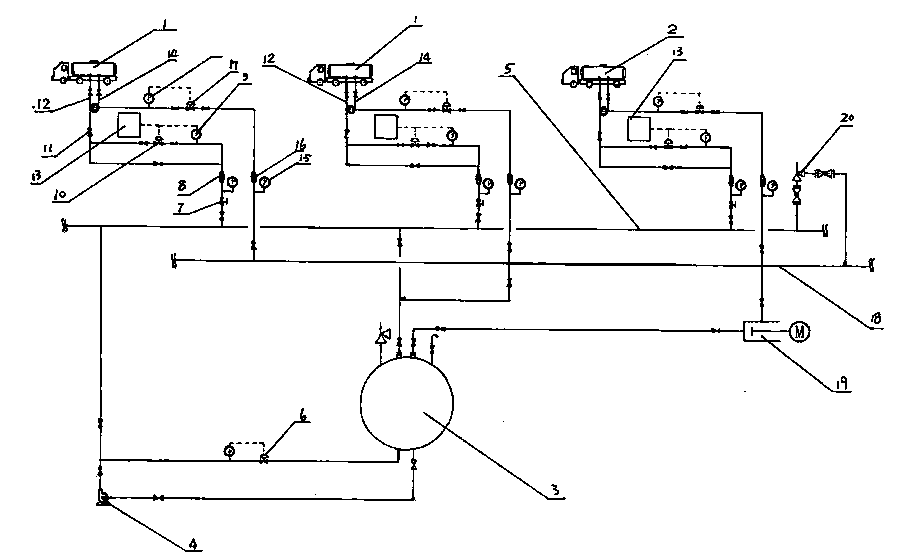

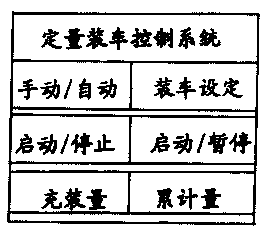

[0026] A (group) limited liability company adopts the present invention, figure 1 It is a structural schematic diagram of the liquid ammonia filling and unloading device of the present invention; figure 2 It is the block diagram of loading and unloading quantitative control system;

[0027] A liquid ammonia filling and unloading device, comprising a liquid ammonia buffer storage tank 3, a loading and unloading arm, and a delivery pump 4, characterized in that the liquid ammonia buffer storage tank 3 is connected to a delivery pump 4, and the delivery pump 4 is connected to a liquid phase main line 5. A return line is also provided at the outlet of the delivery pump 4, and a return control valve 6 is arranged on the return line; the main liquid phase line 5 passes through the quick cut-off valve 7, the flame arrester 8, the mass flow meter 9 and its Regulating valve 10, manual ball valve 11, and liquid ammonia loading and unloading arm 12 are connected to tanker 1 or tanker ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com