Loading and unloading gantry cantilever crane for freight train depot for united transportation of railways and highways and loading and unloading method

A technology for road-rail intermodal transportation and train yard, which is used in transportation and packaging, trolley cranes, load hanging elements, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

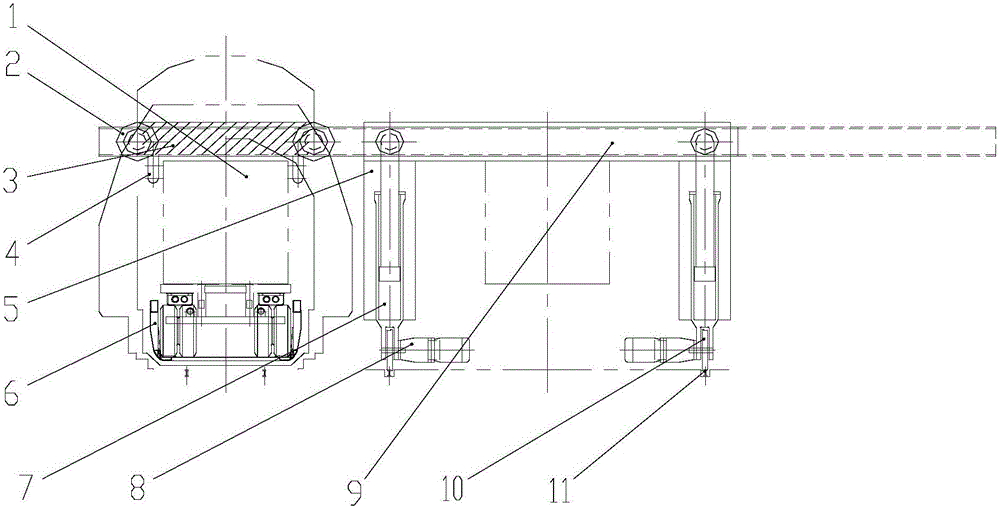

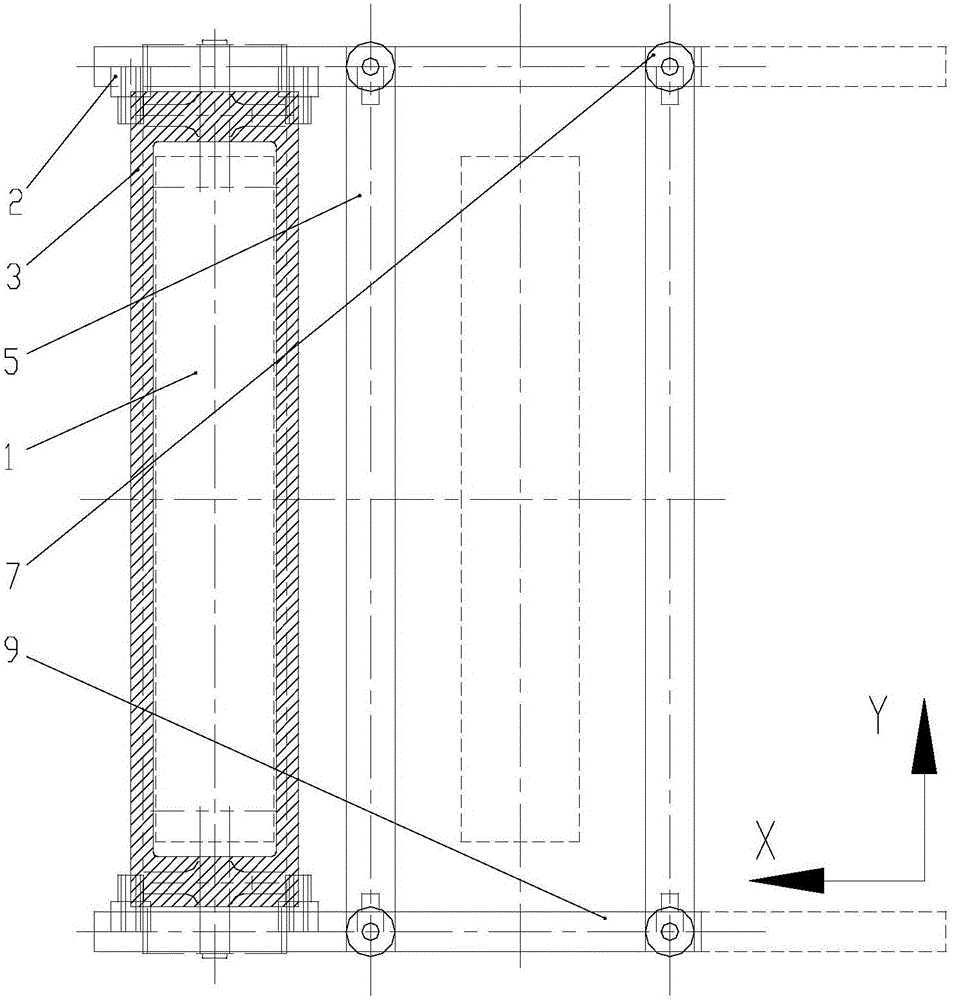

Embodiment 1

[0025] Embodiment 1: The gantry cantilever crane is located outside the boundary of the railway station. Implementation method: when loading 20 feet, 40 feet, 45 feet and 48 feet standard and heavy containers, the spreader 4 will hang the container 1 firmly, and the cart lifting mechanism 7 will The gantry trolley 3 and the container 1 are raised so that the container 1 is higher than the X5 railway freight car 6, and the gantry trolley 3 travels under the drive of the trolley traveling driving mechanism 2, and sends the container 1 directly above the X5 railway freight car 6, and the cart lifting mechanism 7 Put the gantry trolley 3 and the container 1 down, and the container 1 enters the 6th compartment of the X5 railway freight car, and the position error of the X direction and the Y direction on the horizontal plane is ±20mm (illustration: the X direction is perpendicular to the railway track, and the Y direction is parallel to the railway track) so that the container 1 The...

Embodiment 2

[0026] Embodiment 2: When unloading standard and heavy containers of 20 feet, 40 feet, 45 feet and 48 feet, the gantry trolley 3 first moves to the top of the X5 railway wagon 6, and the trolley lifting mechanism 7 lowers the gantry trolley 3 to make the spreader 4 pairs Lock the socket hole of the container 1 and hang the container 1 securely. The trolley lifting mechanism 7 raises the gantry trolley 3 and the container 1 so that the container 1 is higher than the X5 railway freight car 6. The gantry trolley 3 moves under the drive of the trolley driving mechanism 2. , the container 1 is sent directly above the railway platform, the cart lifting mechanism 7 puts the gantry trolley 3 and the container 1 down, and the container 1 enters the trailer compartment, and the position error of the X direction and the Y direction of the horizontal plane is ±20mm (illustration: the X direction and the railway The rail is vertical and the Y direction is parallel to the railway rail) so th...

Embodiment 3

[0027] Embodiment 3: The gantry cantilever crane is located outside the boundary of the railway station. Implementation method: When loading a 40-foot-long three-axle van semi-trailer or a 45-foot-long four-axle van semi-trailer, the spreader 4 will hang the semi-trailer 1 Firmly, the cart lifting mechanism 7 raises the gantry trolley 3 and the semi-trailer truck 1, so that the wheel of the semi-trailer truck 1 is higher than the X5 railway freight car 6, and the gantry trolley 3 walks under the drive of the trolley walking drive mechanism 2, and the semi-trailer truck 1 is sent directly above the X5 railway freight car 6, and the cart lifting mechanism 7 puts the gantry trolley 3 and the semi-trailer 1 down, and the semi-trailer 1 enters the compartment of the X5 railway freight car 6, and the position error in the X direction and the Y direction of the horizontal plane is ±20mm (Fig. Shown: the X direction is perpendicular to the railway rail, and the Y direction is parallel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com