Movable shears-fork type lift

A lift and scissor technology, applied in the field of mobile scissor lifts, can solve problems such as hidden safety hazards, large torque on rotating bearings, lift tilt, etc., and achieve the effects of improving loading and unloading efficiency, high loading and unloading stability, and small tire wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better understand the present invention, the embodiments of the present invention will be explained in detail below with reference to the accompanying drawings.

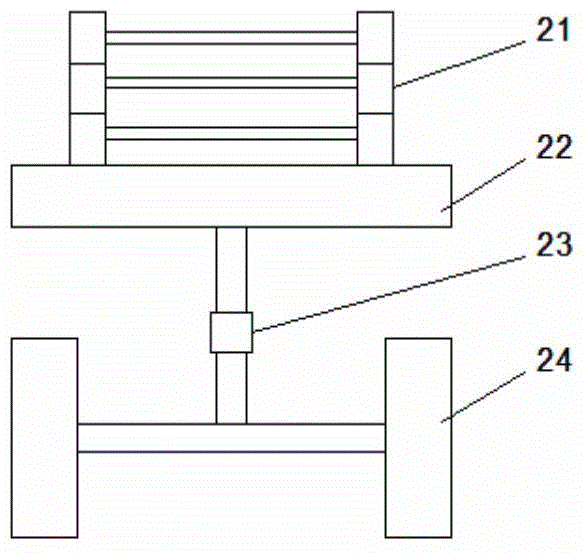

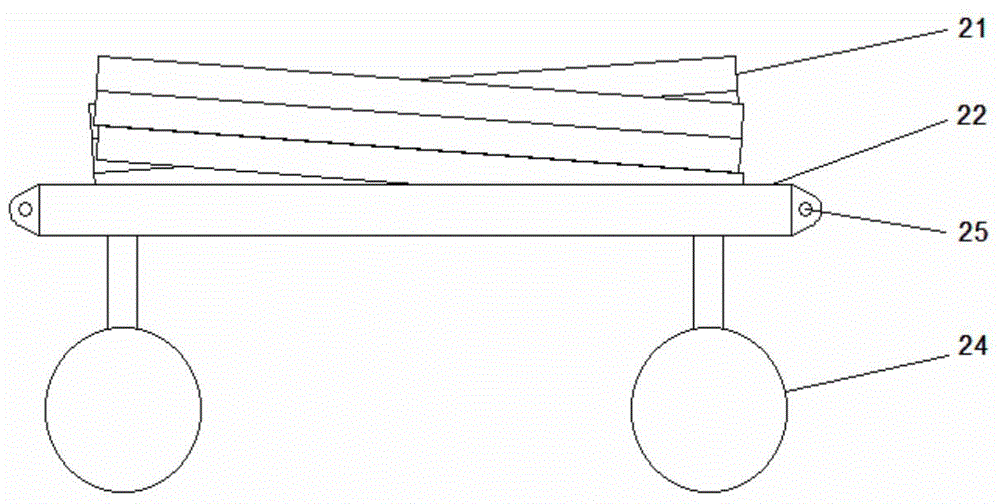

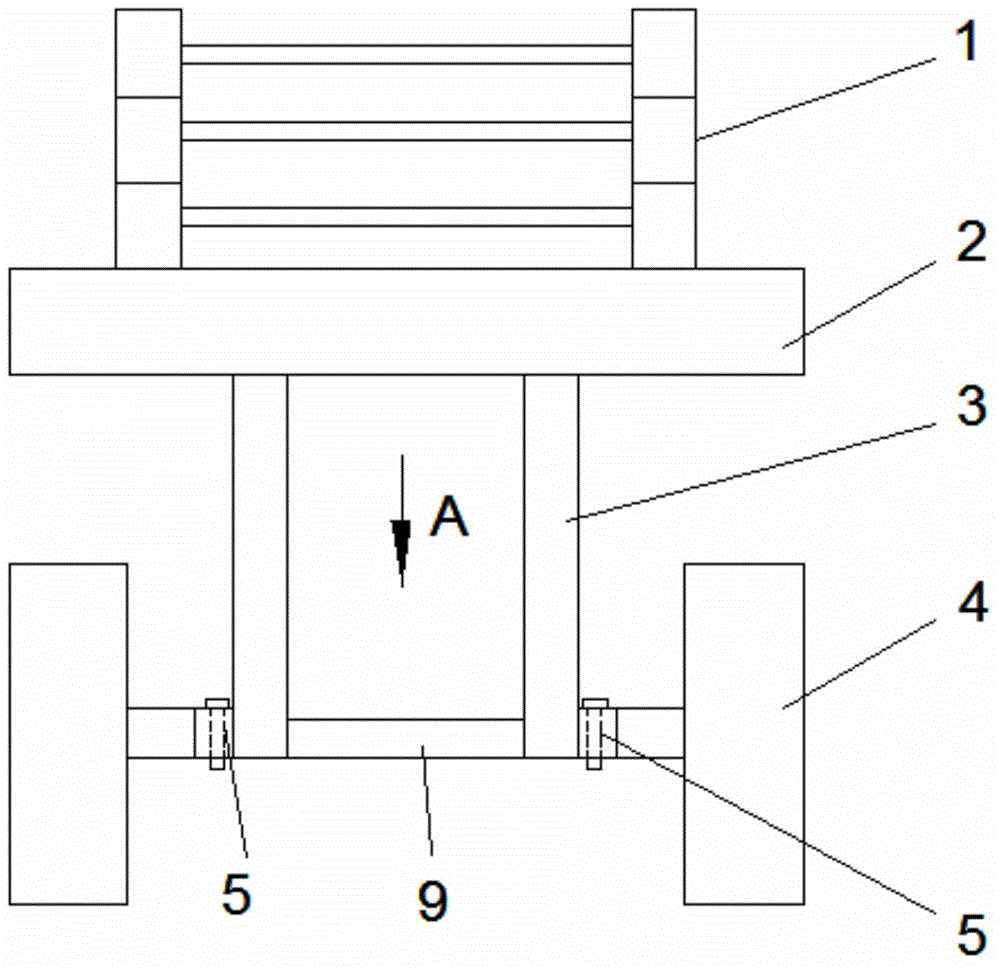

[0022] Such as Figure 3 to Figure 6 As shown, a mobile scissor lift includes a base frame 2, a front wheel 4, and a rear wheel 12. The upper part of the base frame 2 is provided with a scissor arm 1, and a bracket 11 is provided between the two scissor arms 1. The bottom of the underframe 2 is connected to the front axle 9 by a vertical support rod 3, the support rod 3 is provided with two, the front axle is provided with a rotating shaft 5 outside the support rod 3, and the front shaft 9 and the rotating shaft 5 are universal The outer end of the rotating shaft is connected with the front wheel 4, and the front wheel 4 is connected with the front wheel steering mechanism. The steering structure includes a trapezoidal arm 6, a tie rod 7, a shift fork 8, and the front end of the shift fork 8 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com