Bobbin fixing device

A technology of fixing device and bobbin, which is applied in the directions of transportation and packaging, transportation of filamentous materials, and processing of thin materials, etc. It can solve the problems of poor applicability, yarn breakage, and shorten the service life of bobbins, and achieve the effect of convenient loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

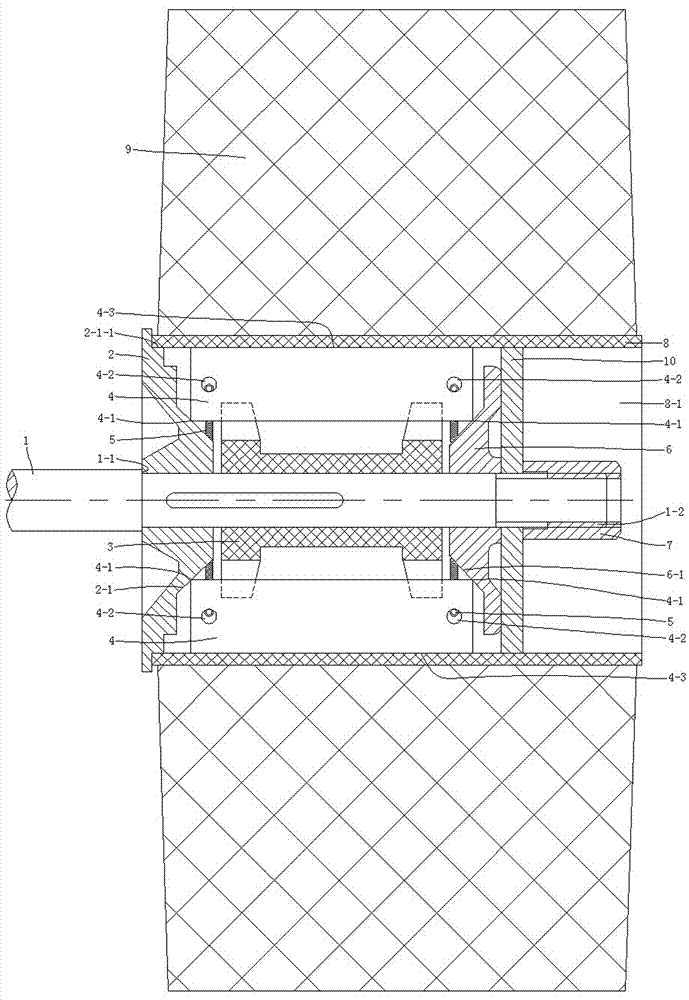

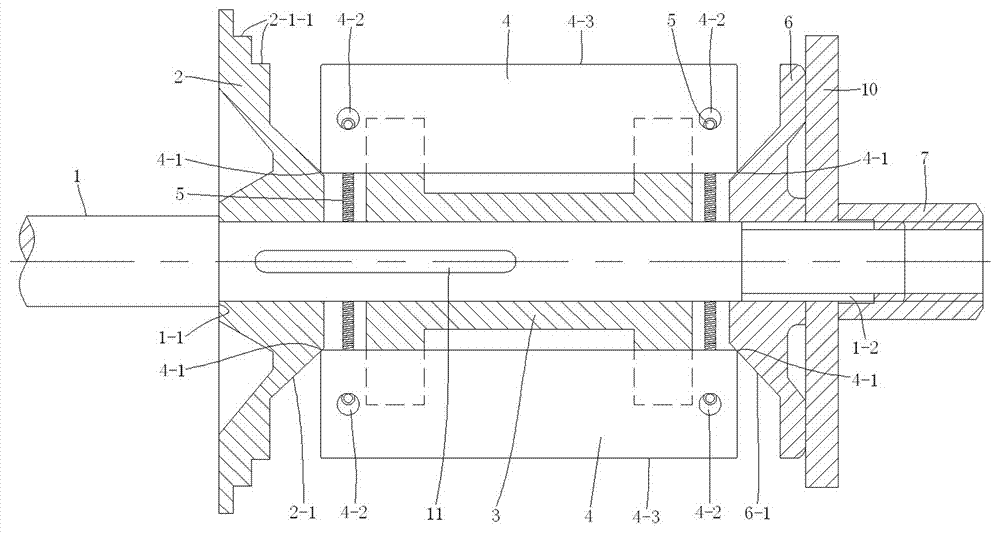

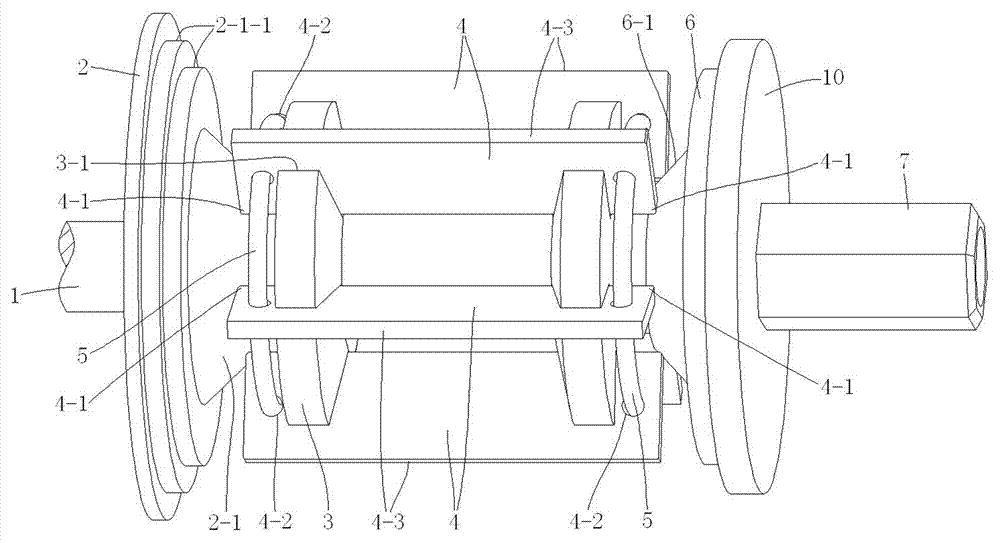

[0023] see Figure 1 to Figure 9 A yarn bobbin fixing device as shown includes a rotating shaft 1, the yarn bobbin 8 is cylindrical and a yarn 9 is wound on its outer wall surface, and the rotating shaft 1 is placed in the inner hole of the yarn bobbin 8. In 8-1, during operation, the yarn bobbin 8 rotates together with the rotating shaft 1, and the yarn 9 is pulled out from the yarn bobbin 8, thereby realizing the unwinding of the yarn. The yarn bobbin fixing device further includes a first The expansion block 2, the guide block 3, the expansion piece 4, the ring spring 5, the second expansion block 6 and the tightening nut 7; the shaft body at one end of the rotating shaft 1 is provided with a stepped surface 1-1, and the other end of the rotating shaft 1 The body is provided with a threaded section 1-2, and the tightening nut 7 is screwed on the threaded section 1-2; the first expansion block 2 is a hollow truncated cone with a conical surface 2-1, and the first expansion b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com