Large diameter cylinder type graphite electrode giant electric furnace

A graphite electrode, cylindrical technology, applied in the direction of electric furnace heating, furnace, furnace components, etc., can solve the problems of high energy consumption, unsafe production operation, difficulty in replacing graphite electrodes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

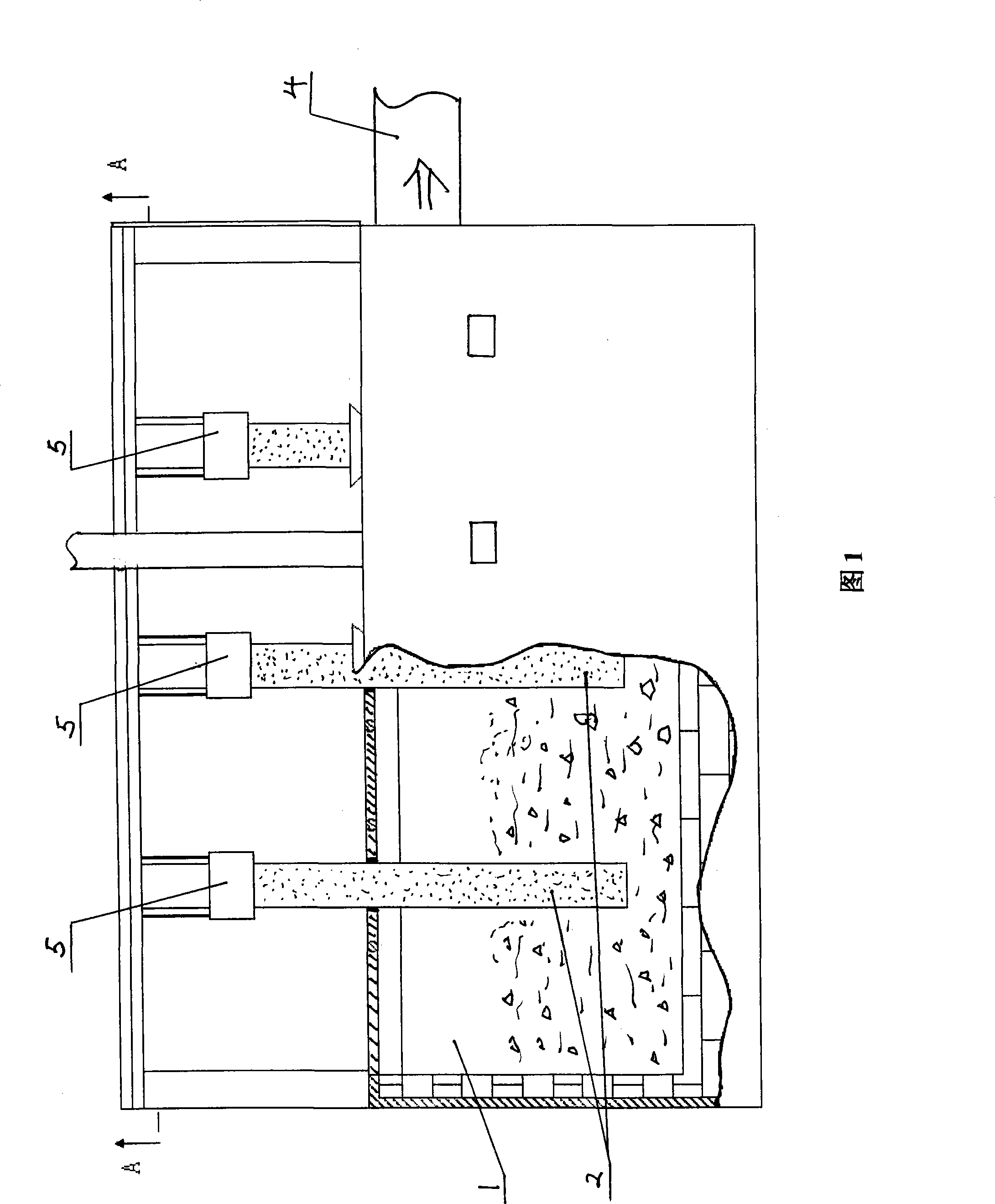

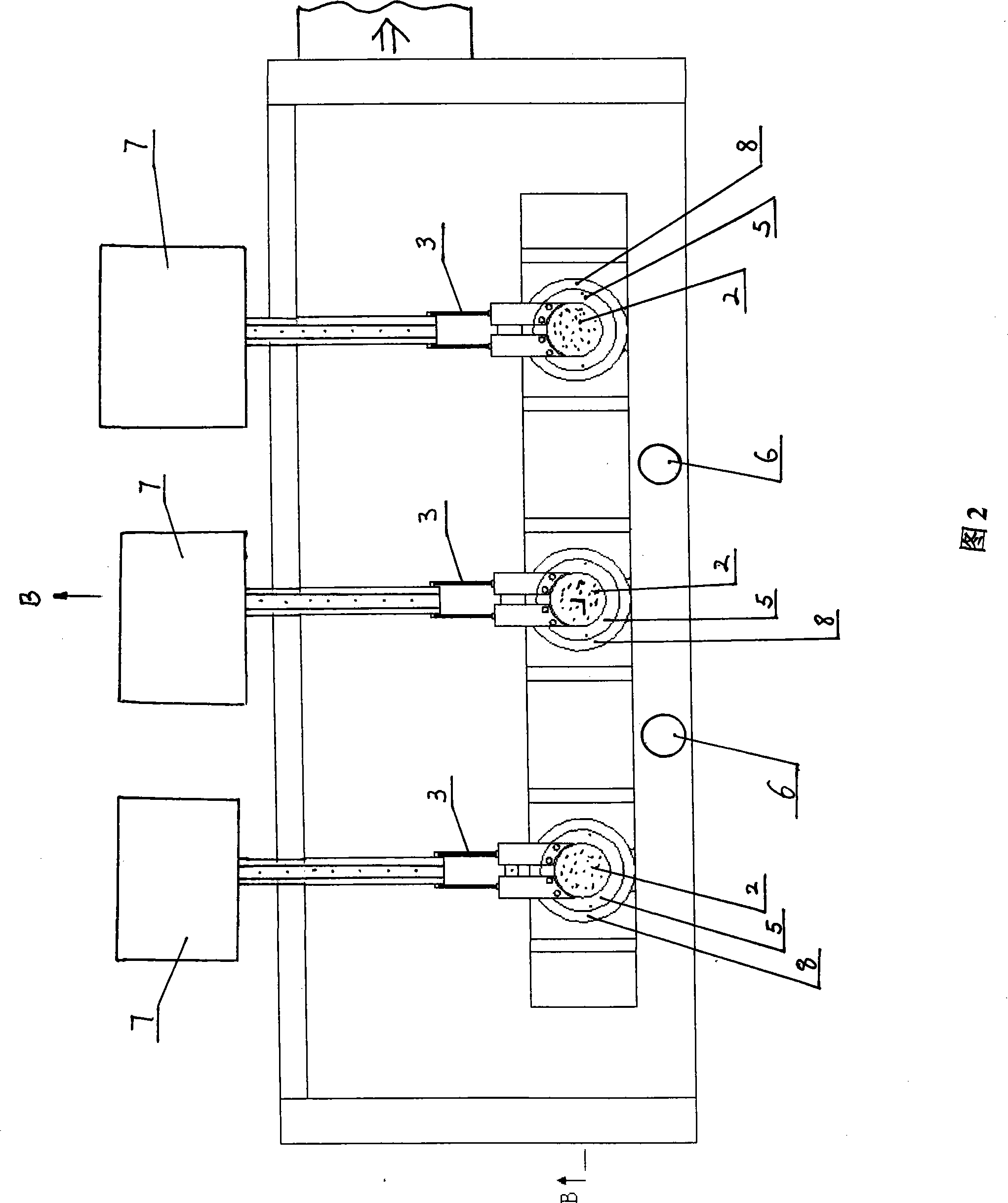

[0015] According to the structure shown in Fig. 1, the location is selected to make the hearth (1) of a sealed giant zinc-smelting electric furnace body. The closed hearth of the electric furnace (1) is built with refractory bricks with high density, good wear resistance and sufficient strength inside, such as aluminum chrome bricks; the outside is built with a layer of insulation bricks, and the outer layer can have a water jacket shell made of steel plate , A layer of asbestos board or aluminum silicate fiber felt can be lined between the insulation brick and the steel plate shell. In order to prevent the leakage of zinc vapor, the mortar joints of the bricks should be kept less than or equal to 2mm. In order to prevent deformation of the shell steel plate, channel steel or angle steel is often added as reinforcement. There is a furnace gas outlet (4) on the upper side of the inner wall of the airtight cavity of the furnace body of the electric furnace (1), and the furnace ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com