Thread wrench with smooth disassembling and assembling effect

A thread and smooth technology, applied in the direction of wrenches, screwdrivers, manufacturing tools, etc., can solve the problem that the threaded wrench cannot be removed smoothly, and achieve the effect of simple structure, convenient assembly and reliable loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

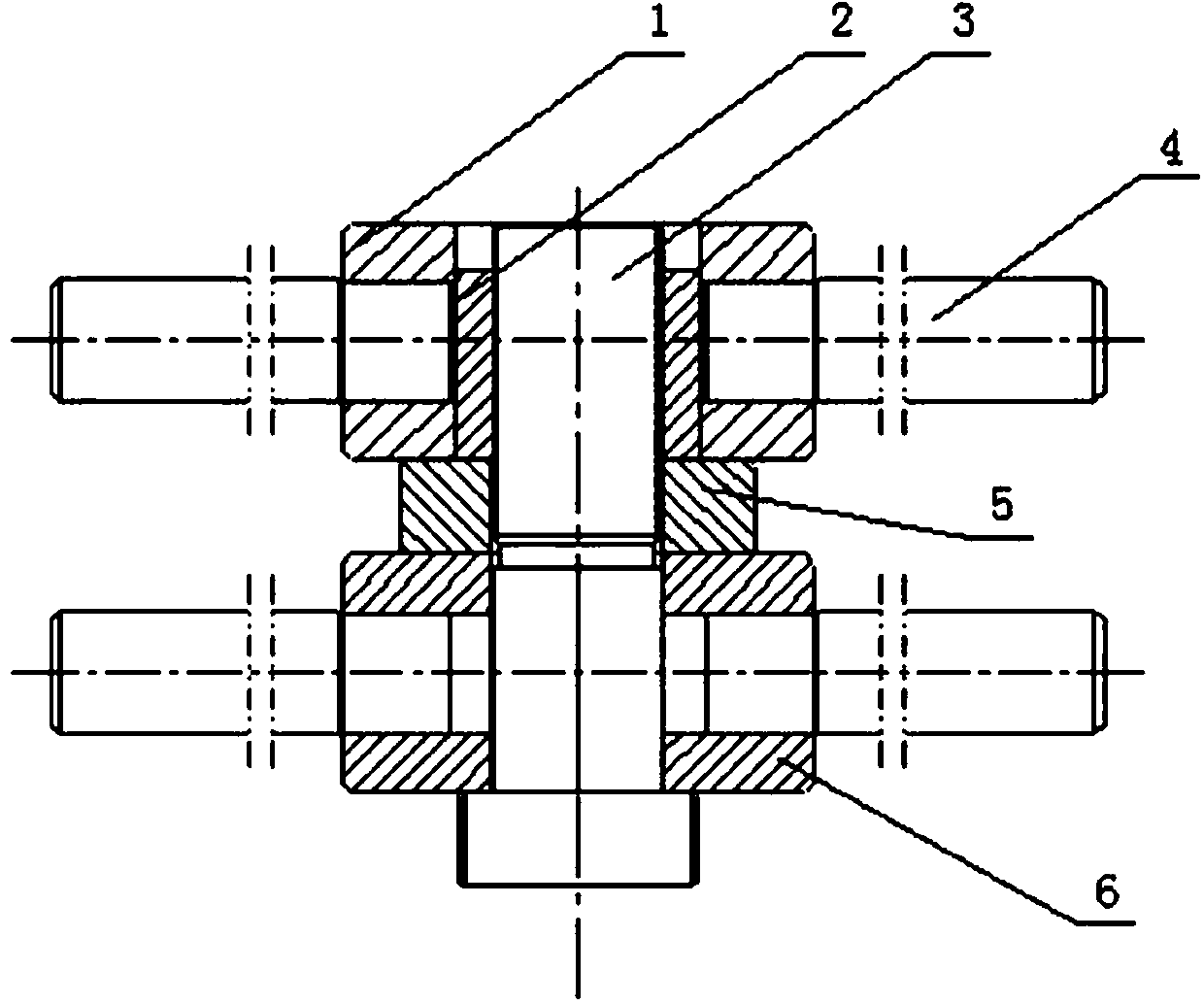

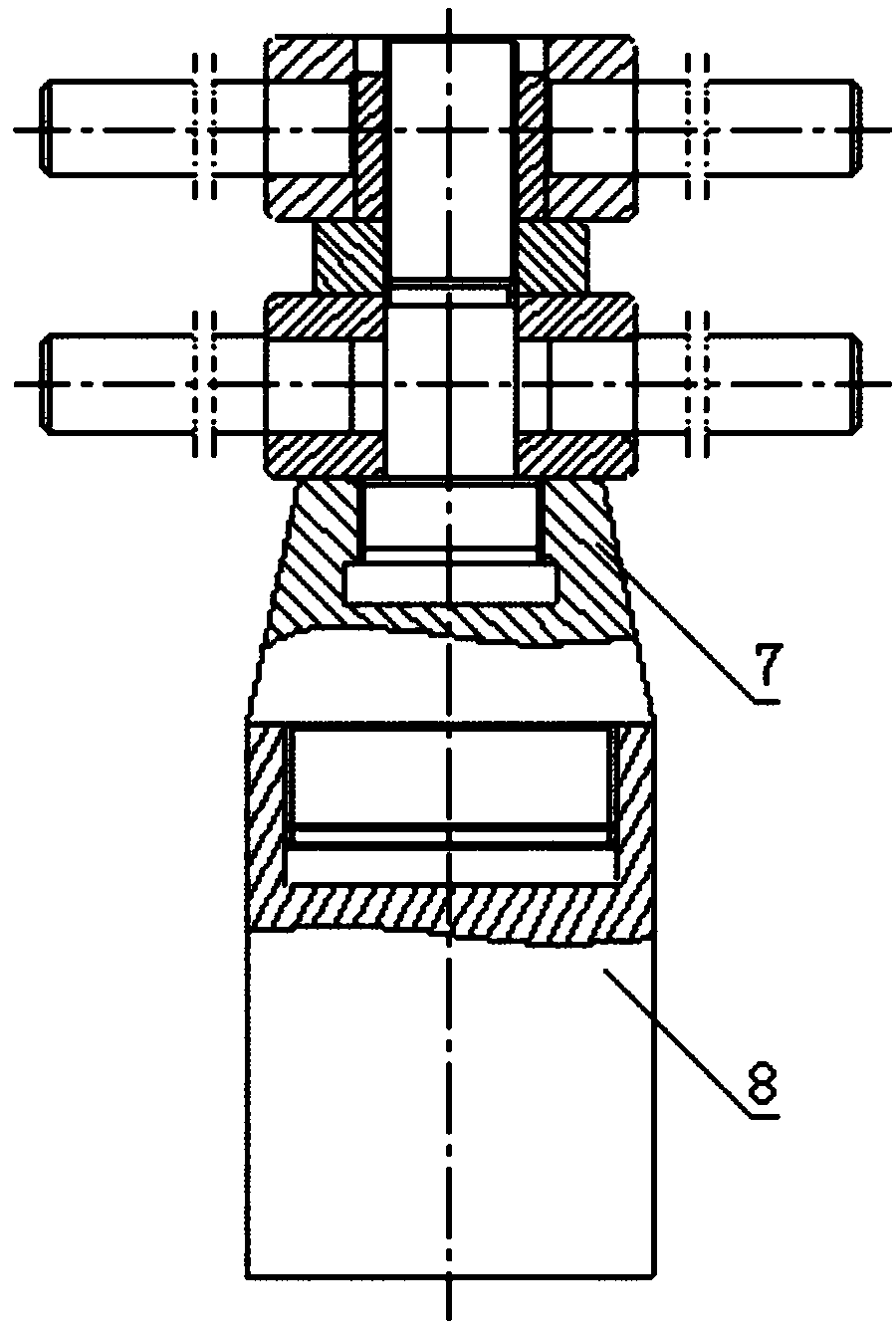

[0019] A kind of screw wrench that can be disassembled smoothly of the present invention, as figure 1 As shown, including center column 3, hex nut 2, upper wrench set 1, lower wrench set 6, washer 5 and wrench rod 4;

[0020] The sidewalls at the upper and lower ends of the central column 3 are respectively processed with threaded sections with opposite thread directions. The external thread of the threaded section at the lower end of the central column 3 matches the internal thread of the threaded hole of the assembly part, and the length of the threaded section at the lower end of the central column 3 is shorter than that of the assembly part. The depth of threaded hole, the middle part of central column 3 is the connection section of regular hexagon, and the outer diameter of threaded section of central column 3 lower ends is greater than the outer diameter of the circumscribed circle of central column 3 middle part connection section; The threads of the threaded section at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com