Electrophoretic painting device for car door

A technology for electrophoretic painting and car doors, which is applied in the directions of electrolytic paint, electrophoretic plating, and coating, and can solve the problems of car door prolapse and low versatility of electrophoretic paint tooling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

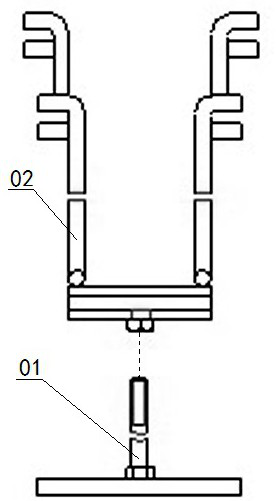

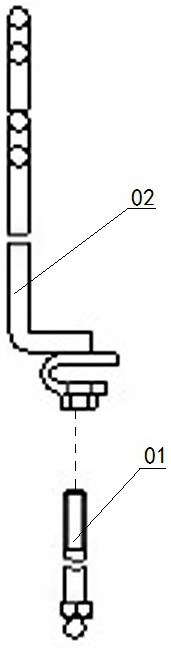

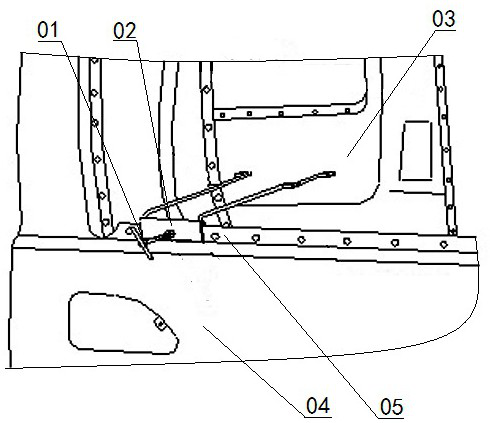

[0022] The car door electrophoretic painting device shown in 7 includes a support rod 1. The support rod 1 in this embodiment has a vertical rod section 1-2 with a limit block 1-3 welded at one end and the other end of the vertical rod section 1-2 is connected. The horizontal bar section 1-1, the vertical bar section 1-2 and the horizontal bar section 1-1 are arranged at right angles, and the angle c between the vertical bar section 1-2 and the horizontal bar section 1-1 in this embodiment is 90° °; the other end of the cross bar section 1-1 is connected with a lower folding bar section 1-4 inclined to the limit block 1-3 side, and the folding bar section 1-4 is connected with an upper folding bar section 1-5; The angle d between the horizontal bar section 1-1 and the lower folding bar section 1-4 of the embodiment is 105°, and the included angle f between the lower folding bar section 1-4 and the upper folding bar section 1-5 is 130° °, the above-mentioned included angle c, i...

Embodiment 2

[0024] The car door electrophoretic painting device shown in 7 includes a support rod 1. The support rod 1 in this embodiment has a vertical rod section 1-2 with a limit block 1-3 welded at one end and the other end of the vertical rod section 1-2 is connected. The horizontal bar section 1-1, the vertical bar section 1-2 and the horizontal bar section 1-1 are arranged at right angles, and the angle c between the vertical bar section 1-2 and the horizontal bar section 1-1 in this embodiment is 90° °; the other end of the cross bar section 1-1 is connected with a lower folding bar section 1-4 inclined to the limit block 1-3 side, and the folding bar section 1-4 is connected with an upper folding bar section 1-5; The angle d between the horizontal bar section 1-1 and the lower folding bar section 1-4 of the embodiment is 115°, and the included angle f between the lower folding bar section 1-4 and the upper folding bar section 1-5 is 140° °, the above-mentioned included angle c, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com