Environmental protection and safety firecrackers

A safe and firecracker technology, applied in the direction of firecrackers, etc., can solve the problems of large reverse ejection force of the shell, non-moisture-proof paper shell, unstable product quality, etc., and achieve good explosion loudness, good moisture-proof performance, and significant environmental benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

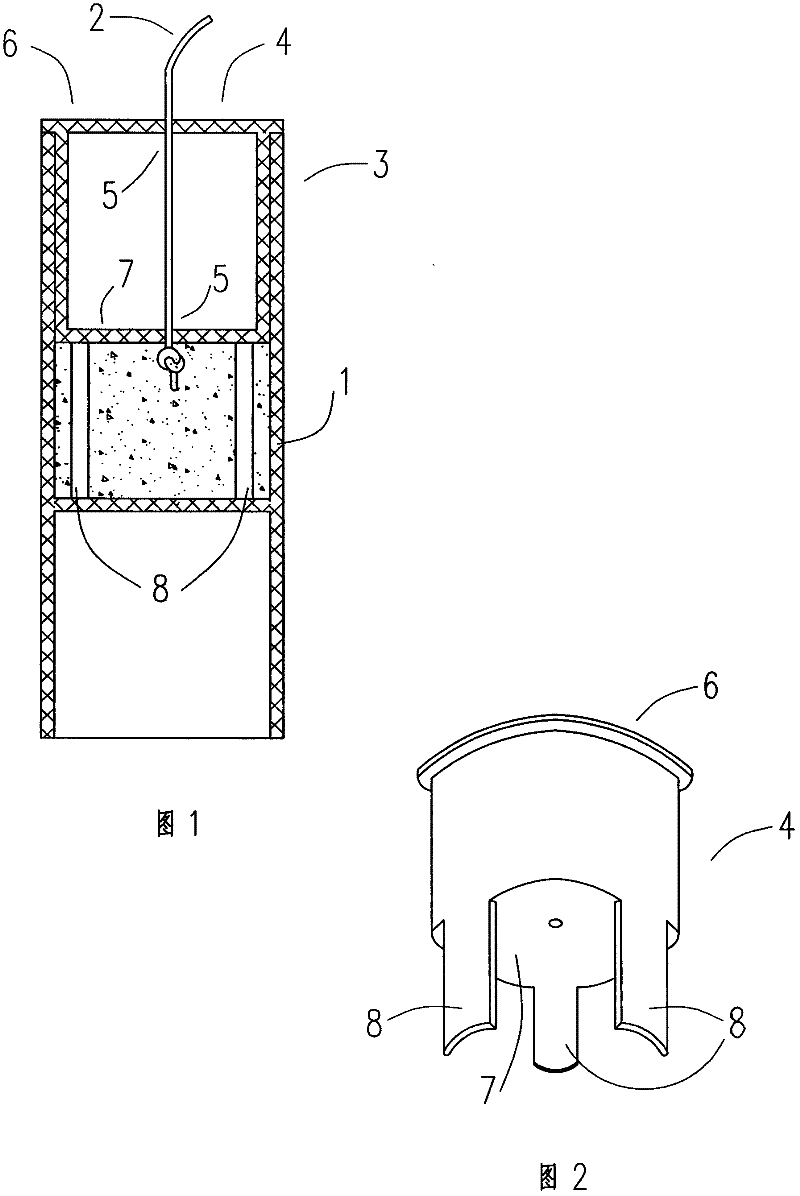

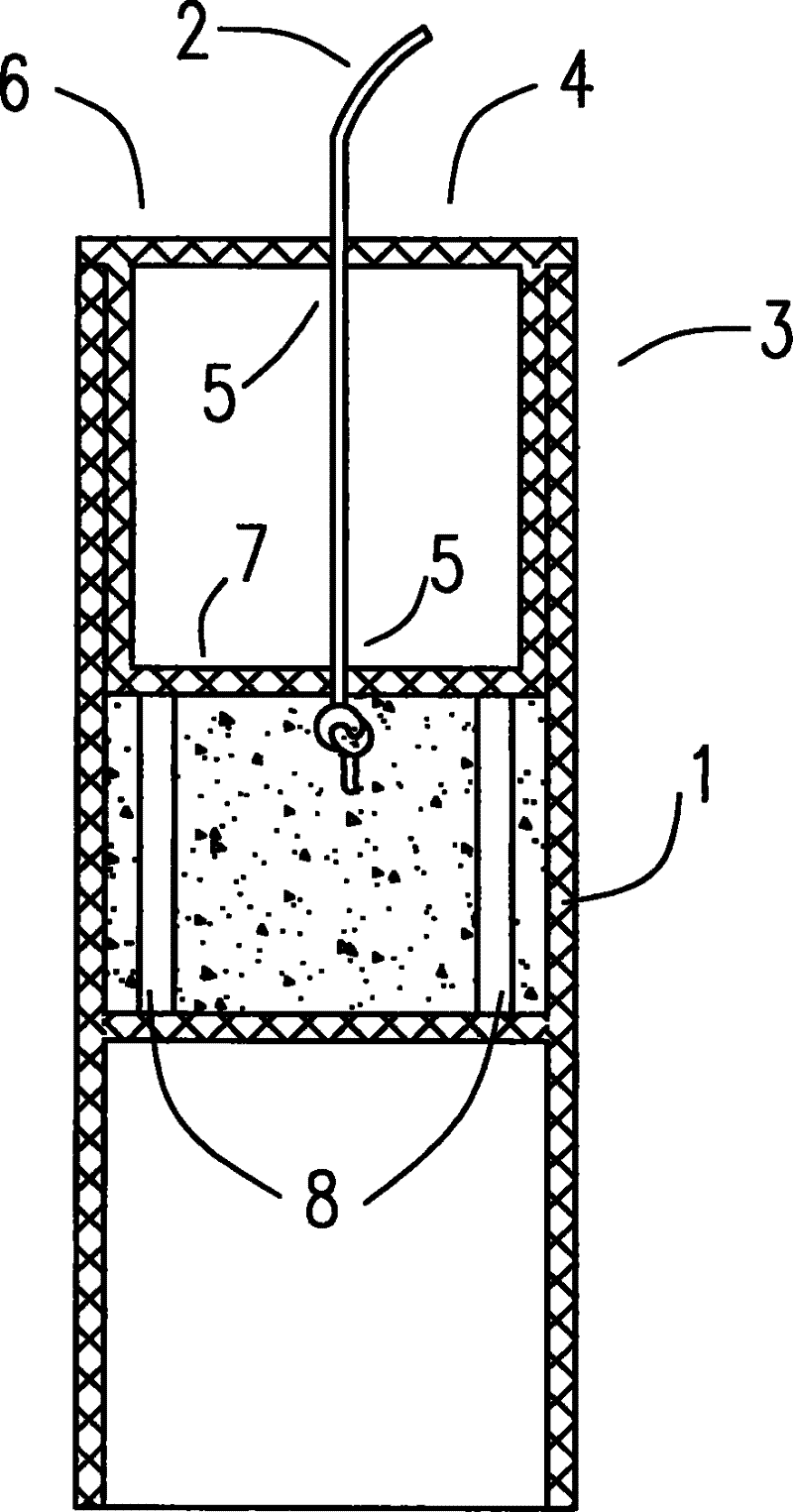

[0010] Such as figure 1 , figure 2 As shown, an embodiment of the present invention includes a housing 1 and a lead wire 2. The housing 1 is a U-shaped plastic molding with an open end 3 and a closed end. The inner cavity of the closed end is provided with a gunpowder portion. The feature is that the housing 1 is a thin-walled housing, and also includes an end cover 4, which is a plastic molded part, and the end cover is provided with lead wire penetration holes 5. The principle is: use a thin-walled plastic shell, a specific example is to use PVC plastic moldings, PVC plastic raw materials can be added with flame retardants, antistatic agents to improve its performance, its thickness is about 0.5mm, the shell The firmness of 1 is equivalent to the firmness of the original paper shell. The explosion gas can explode the shell 1 into plastic pieces. Due to the toughness of the plastic, it will not become fine debris, and there will be no single shell flying. In the case of hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com