Manufacturing method of charging coil stamping

A manufacturing method and charging coil technology, applied in coil manufacturing, transformer/inductor coil/winding/connection, circuit, etc., can solve the problems of easy pollution, complicated manufacturing method, large gap between charging coils, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

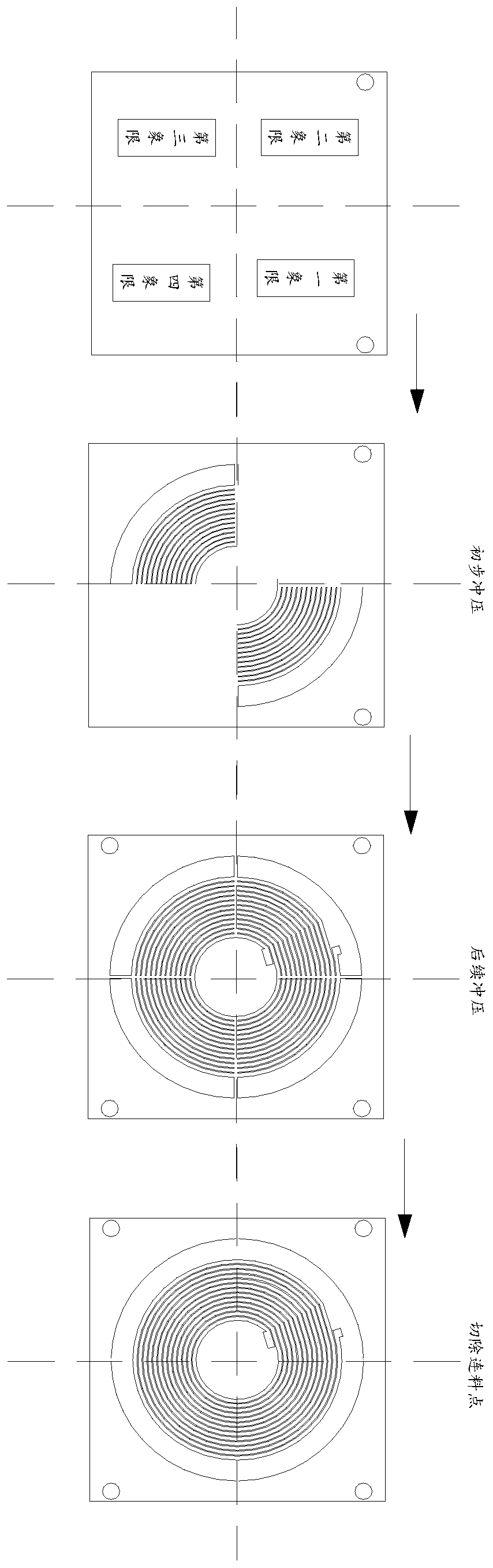

[0040] Attached below Figures 1 to 11 The present invention is described in further detail.

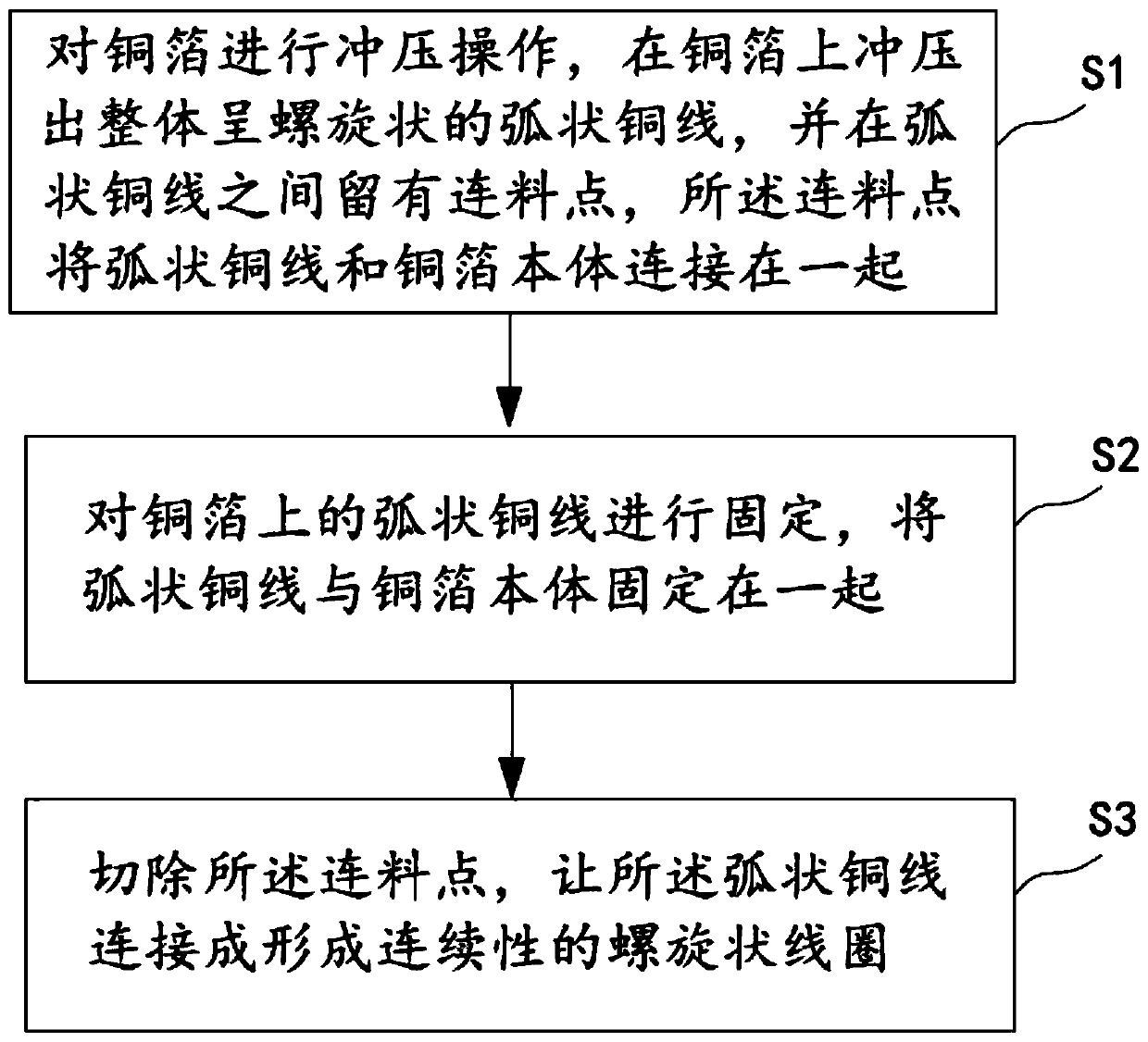

[0041] The invention discloses a charging coil stamping manufacturing method, which includes the following steps:

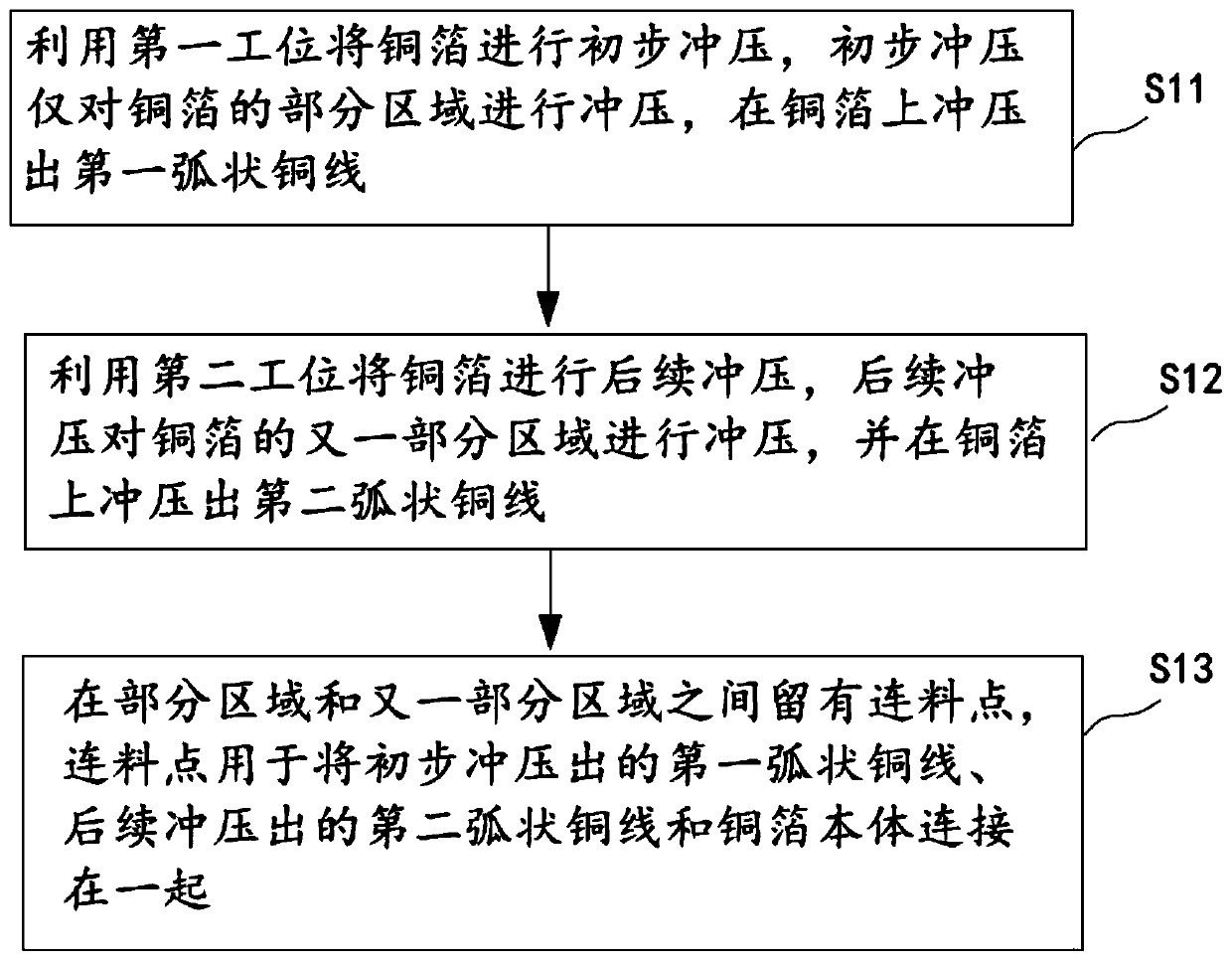

[0042] Step S1: Stamping the copper foil, stamping out the overall spiral arc-shaped copper wire on the copper foil, and leaving a connecting point 201 between the arc-shaped copper wires, the connecting point 201 connects the arc-shaped copper wire and the copper foil the bodies 204 are connected together;

[0043] Step S2: Fix the arc-shaped copper wire on the copper foil, and fix the arc-shaped copper wire and the copper foil body 204 together;

[0044] Step S3: cutting off the connecting point 201, and connecting the arc-shaped copper wires to form a continuous helical coil.

[0045] After the punching operation, a part area will be reserved, that is, there will be a connecting point 201 between the arc-shaped copper wires. The connecting point 201 is used to con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com