Tooth-shaped paper strip carding frame

A paper strip and tooth shape technology is applied in the field of toothed paper processing equipment, which can solve the problems of inability to adjust the spacing, unfavorable production continuity, and toothed paper strips coming out, so as to improve the adjustment flexibility and expand the scope of application of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

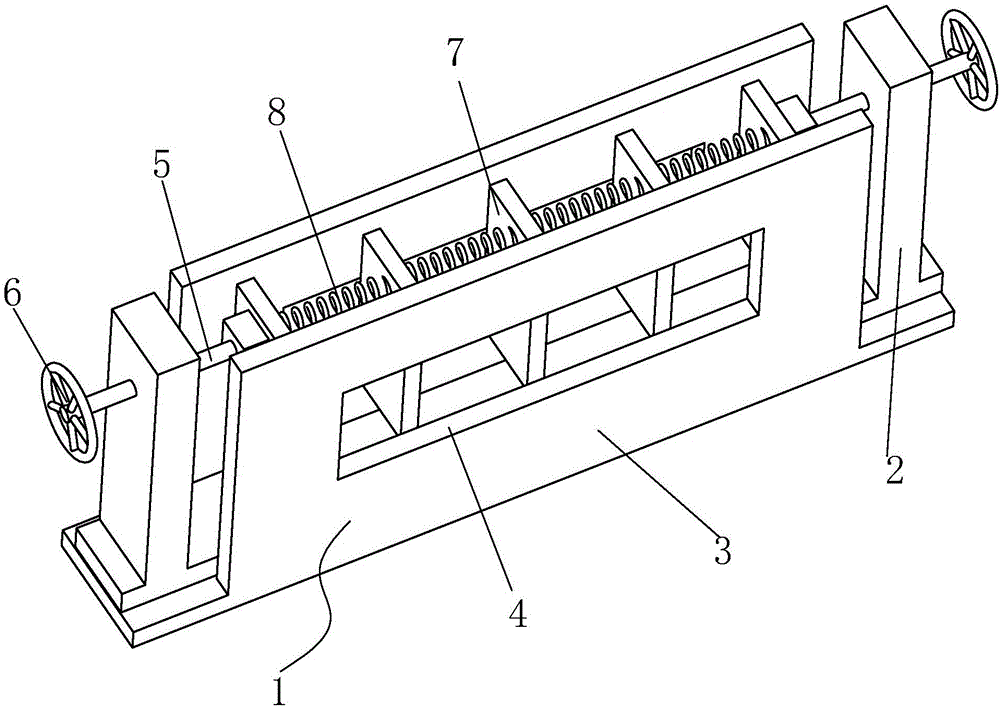

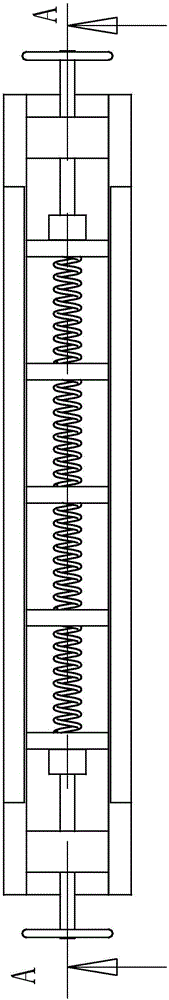

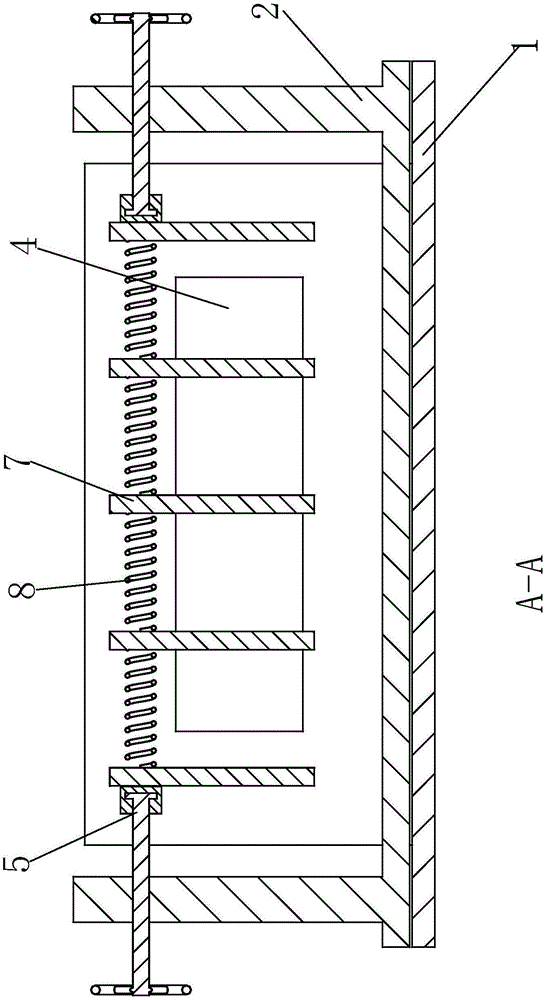

[0018] like Figure 1 to Figure 3 As shown, a toothed paper strip carding frame includes a main frame 1, a support plate 2 is respectively provided on the left and right sides of the main frame 1, and a baffle plate 3 is respectively fixed on the front and rear sides of the main frame 1. A rectangular through hole 4 is provided in the middle part of the baffle plate 3, and a screw rod 5 is horizontally matched in the support plate 2, and a rotating disk 6 for conveniently rotating the screw rod 5 is fixed on the outer end of the screw rod 5; the main body A number of limit plates 7 are uniformly and vertically arranged inside the frame 1, and a spring 8 is respectively fixedly installed between the upper parts of two adjacent limit plates 7, and the bottom of the limit plate 7 extends t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com