Fiber reinforced cement-based foam heat retaining board production line

A fiber-reinforced cement and thermal insulation board technology, applied in ceramic molding workshops, auxiliary molding equipment, supply devices, etc., can solve the problems of easy drop of slurry, reduced efficiency, complicated process, etc., and achieve good product quality, high efficiency, simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

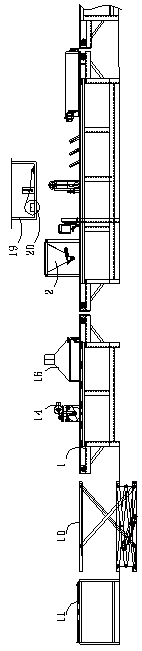

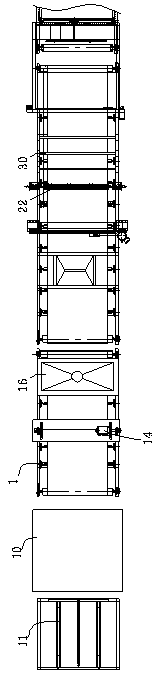

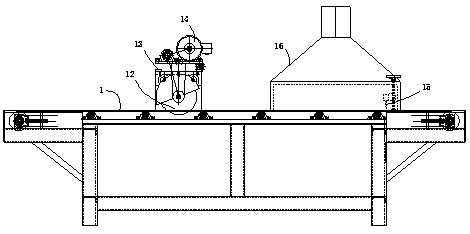

[0052] Best practice: see Figure 1-Figure 6 , a fiber-reinforced cement-based foam insulation board production line, including a conveying platform 1, the upper surface of the conveying platform is a conveying work surface for conveying the substrate from the starting end to the terminal end (during implementation, a conveying belt set with multi-stage connection or Conveying rollers and other mechanisms to obtain the conveying working surface), and the conveying platform 1 is provided with a dust suction device, a material spreading device, a web laying device and a cutting device in sequence from the starting end to the terminal end; the feature is that the material spreading device includes Discharge device, the discharge device includes a storage hopper 2, the storage hopper 2 is located above the conveying platform and the outlet at the lower end is set directly against the conveying working surface; The initial scraping mechanism includes a scraper mounting plate 3, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com