Control valve block system and method for testing hydraulic cylinders

A technology of hydraulic cylinder and control valve, which is used in fluid pressure actuation system testing, fluid pressure actuation device, servo motor components, etc. It can solve the problems of low test efficiency and high work intensity of operators, and it is convenient to reach the oil temperature. Control, improve test efficiency, and simplify the test process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the drawings.

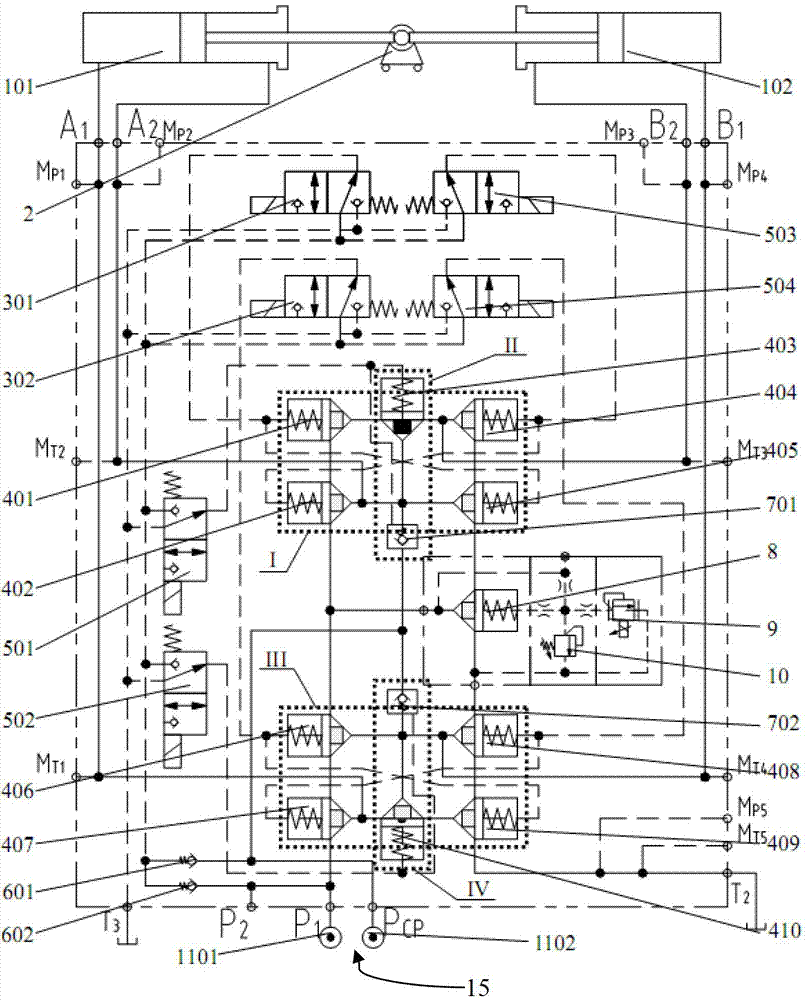

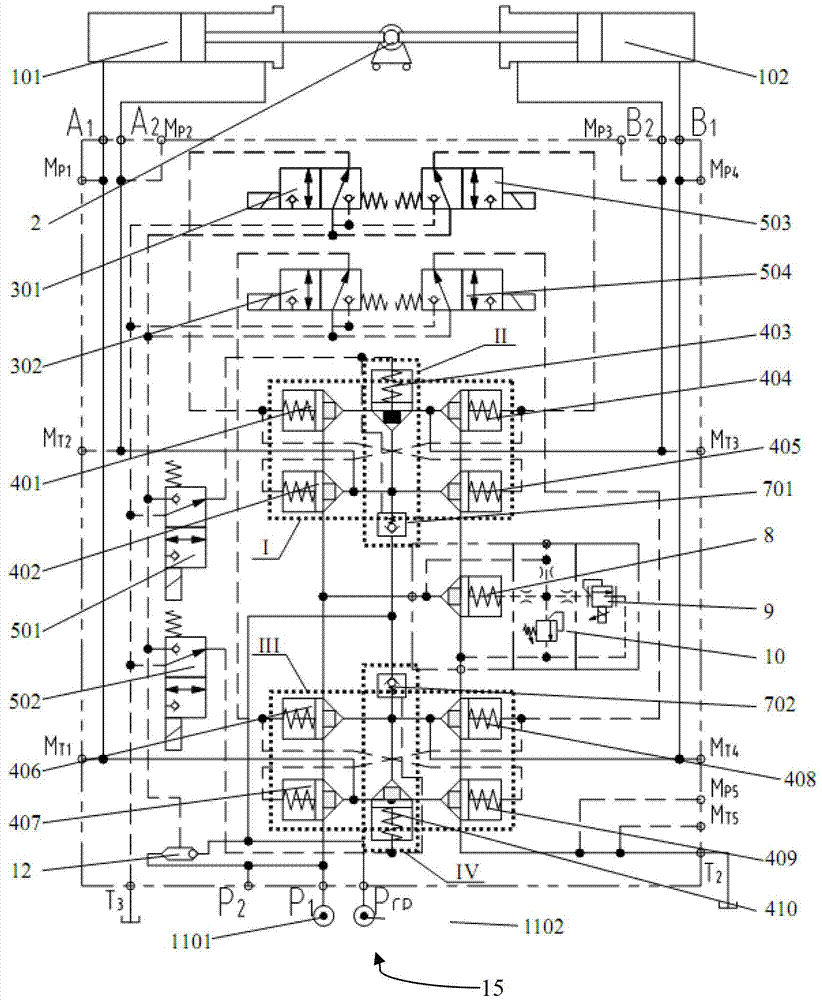

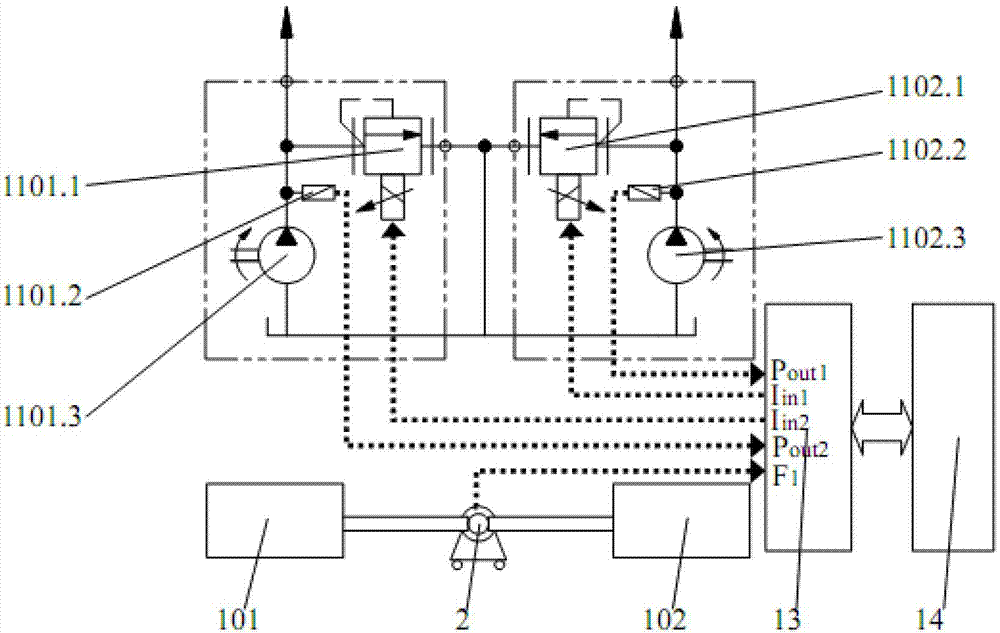

[0024] Reference figure 1 The control valve block system 15 for testing hydraulic cylinders according to the present invention includes two sets of functional reversing valves and two sets of selective reversing valves.

[0025] The first group of functional reversing valves includes cartridge valves 401, 402, 404, and 405; the second group of functional reversing valves includes cartridge valves 406, 407, 408, and 409. Each group of functional reversing valves consists of two two-position three-way reversing valves as pilot control valves. The two-position three-way reversing valve can be an electromagnetic reversing valve.

[0026] In the first group of functional reversing valves: the cartridge valve 401 is connected to the control chamber (ie C cavity) of the cartridge valve 405, and its pilot pressure is controlled by the two-position three-way reversing valve 301; the cartridge val...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com