Distributed driving new wheel-rail high-speed train system

A high-speed train, distributed technology, applied in the field of rail transit, can solve problems such as hindering the acceleration of the train's acceleration performance and increase the maximum speed, and achieve the effects of strong dynamic performance, system safety, and convenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

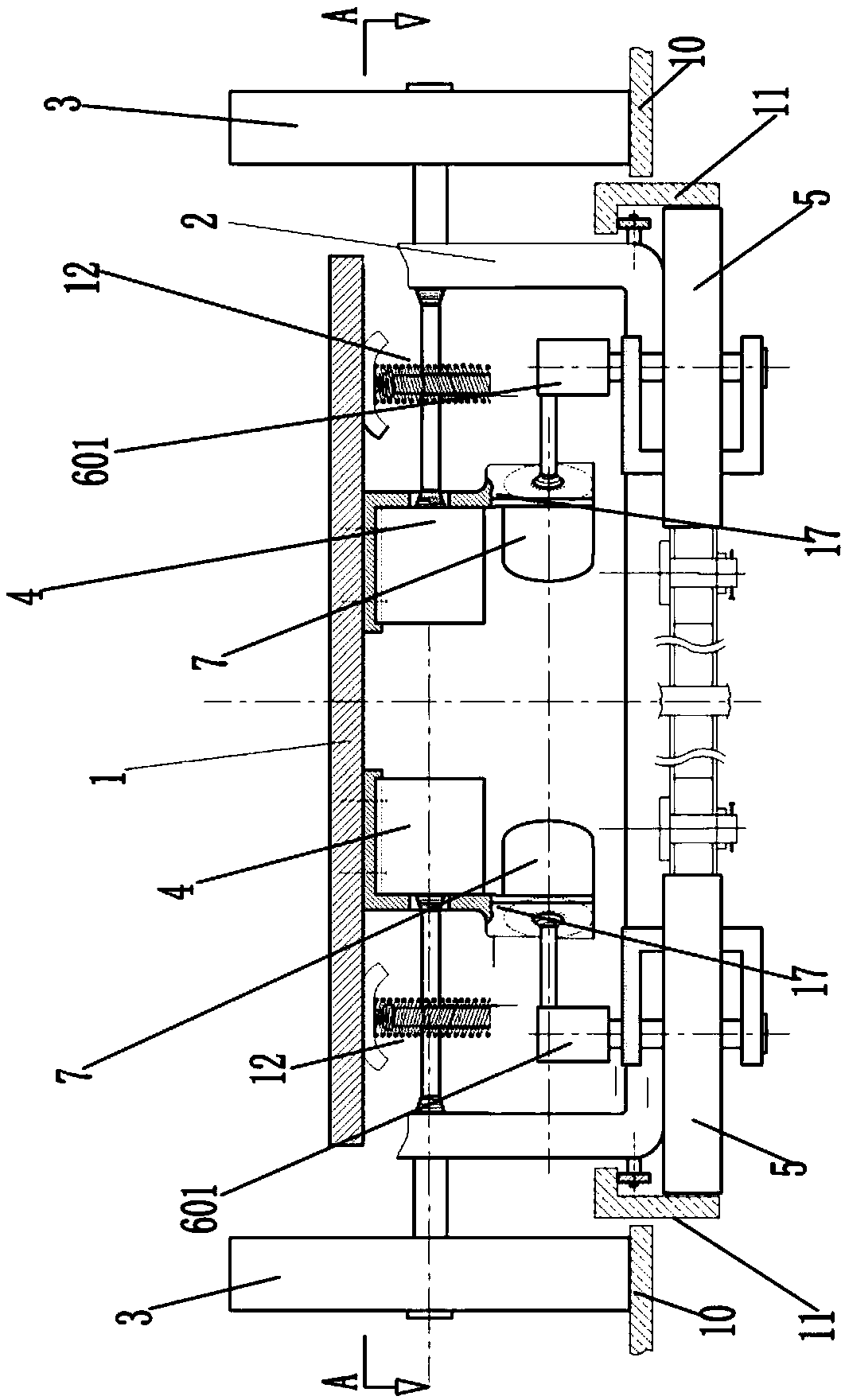

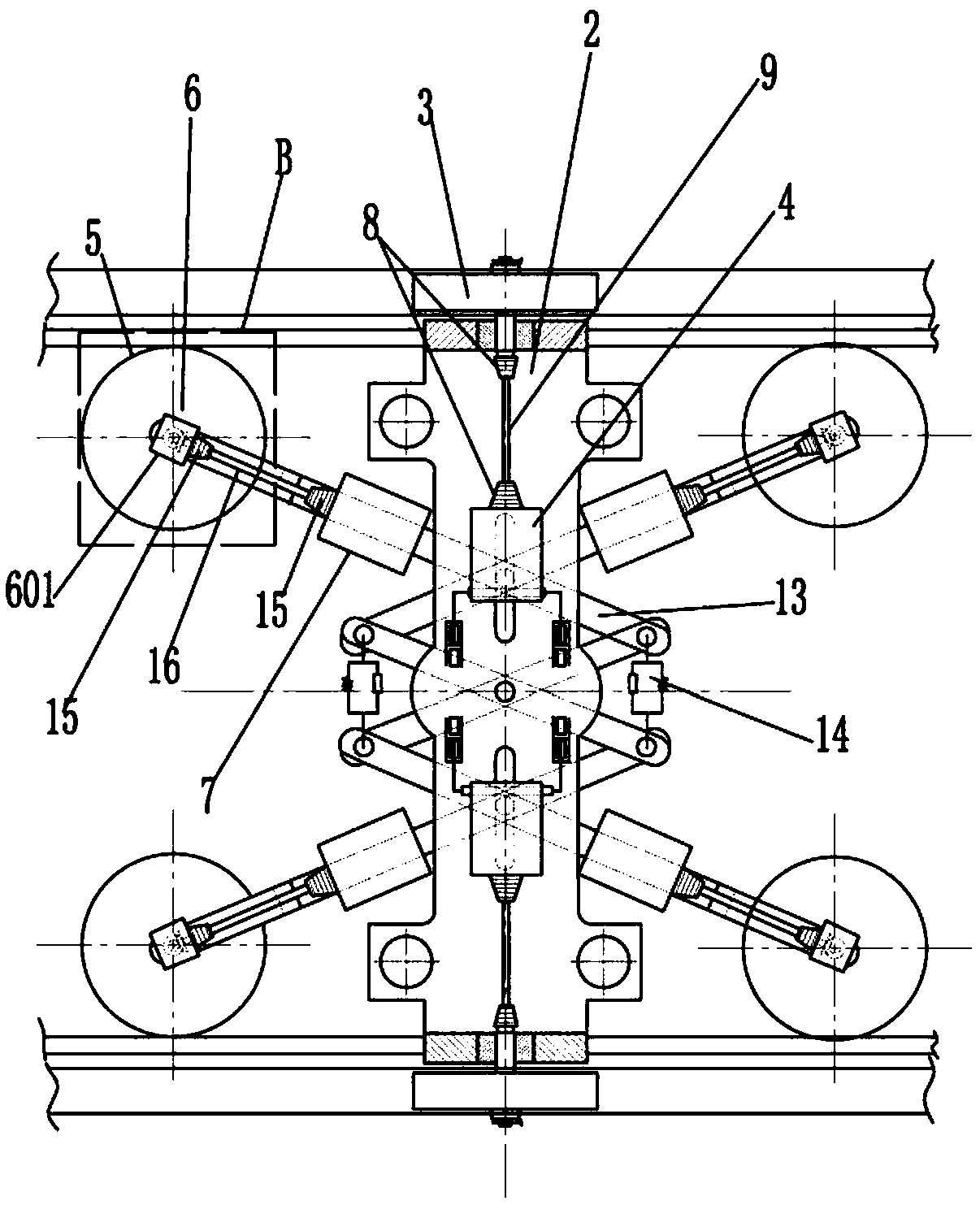

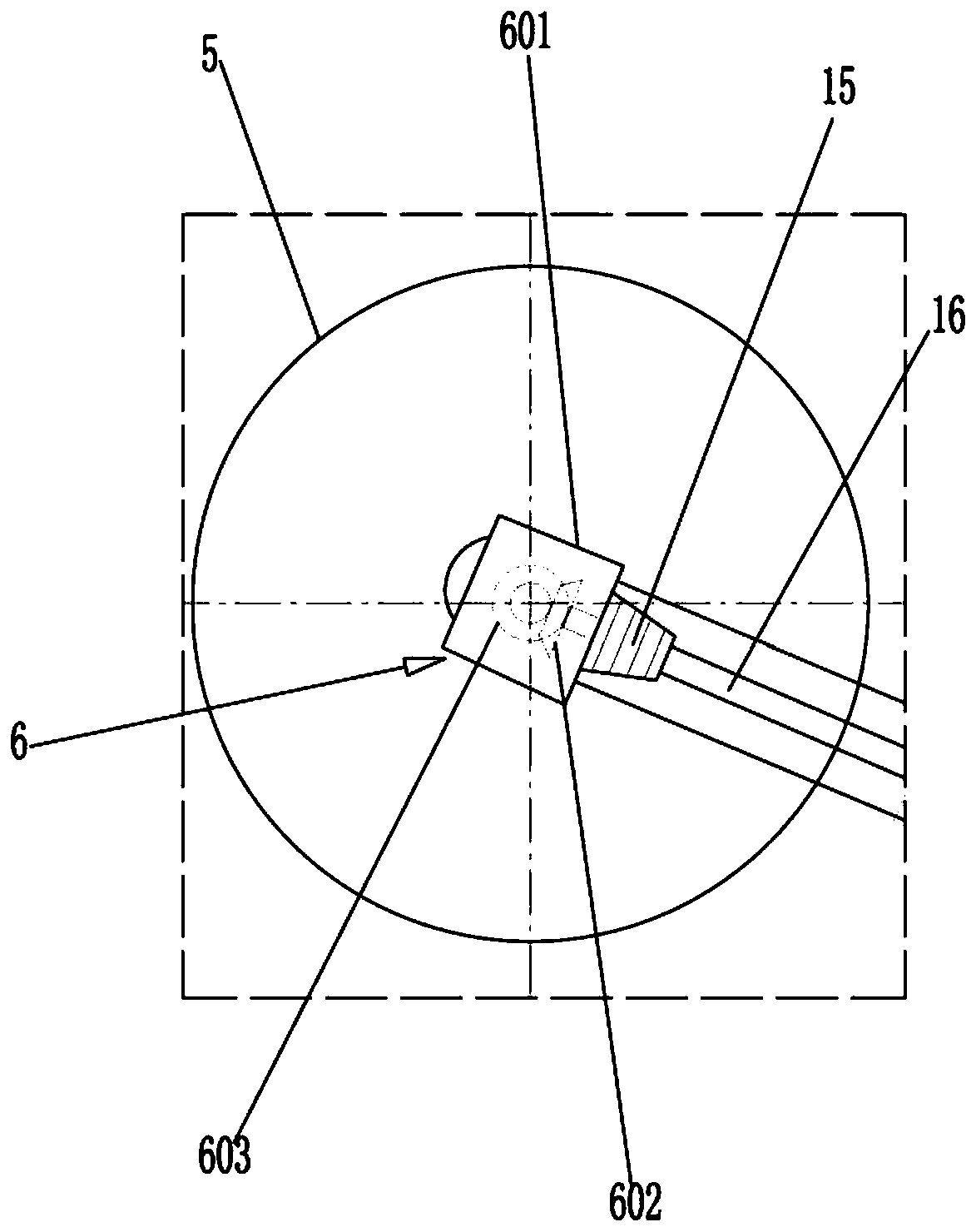

[0022] Such as Figure 1-3 As shown, a distributed drive new wheel-rail high-speed train system includes a plurality of bogie bodies and a pair of track assemblies rollingly matched with the bogie bodies.

[0023] Each track assembly comprises a load-bearing track 10 and a guide track 11, the working surface of the load-bearing track 10 is arranged horizontally, and the working surface of the guide track 11 is vertically arranged.

[0024] Each bogie main body includes a car connecting frame 1, a load-bearing frame 2, a load-bearing wheel 3, a guide wheel 5, a transverse telescopic linkage mechanism 13, a spring damping assembly 14, a shock absorbing assembly 12, and a motor installed on the car connecting frame 1. The mounting frame 17, wherein the carriage connecting frame 1 is horizontally rotatably installed on the bottom side of the carri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com