A quick-change valve hot forging die and its installation method and disassembly method

An installation method and technology of hot forging dies, applied in forging/pressing/hammer devices, forging/pressing/hammering machinery, manufacturing tools, etc., can solve the problems of high forging temperature, short service life and waste of materials for valves, and achieve Save material, save operation time, simple and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below.

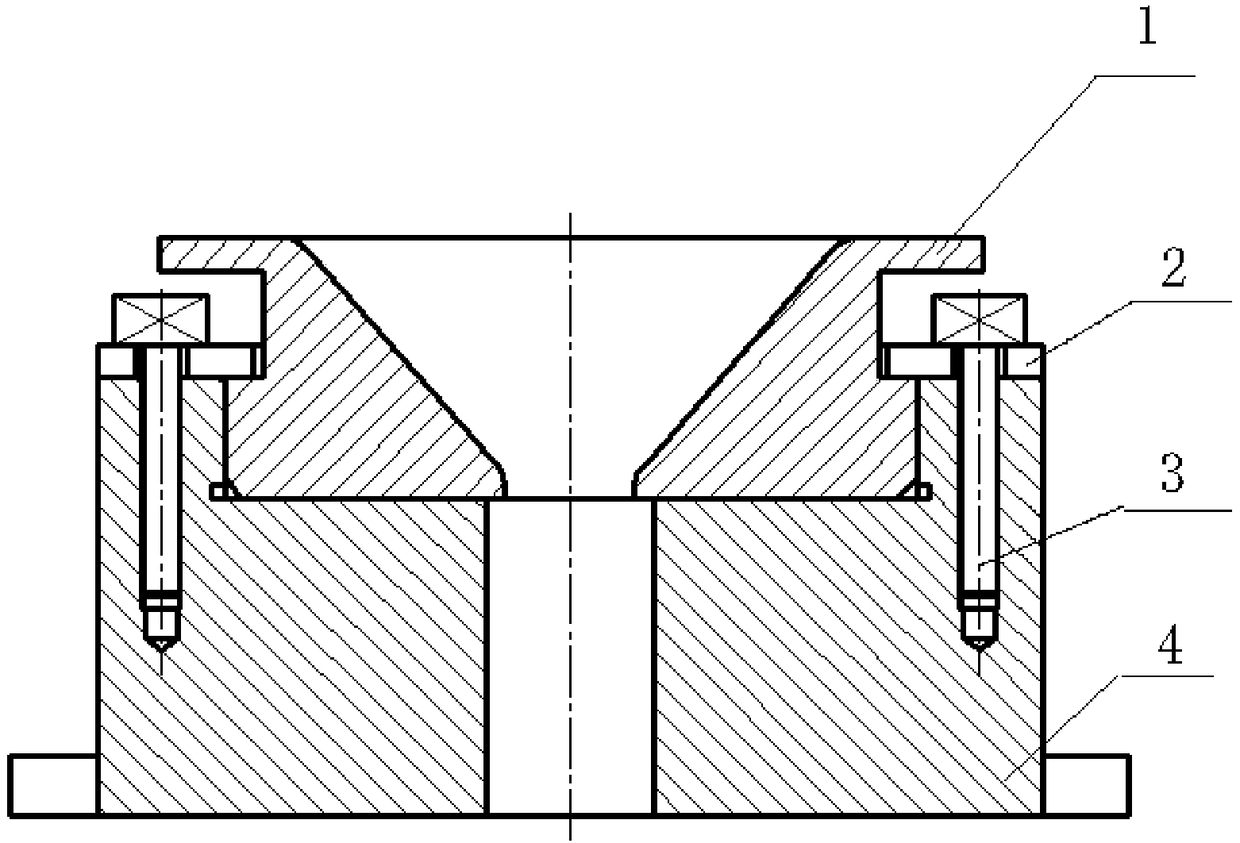

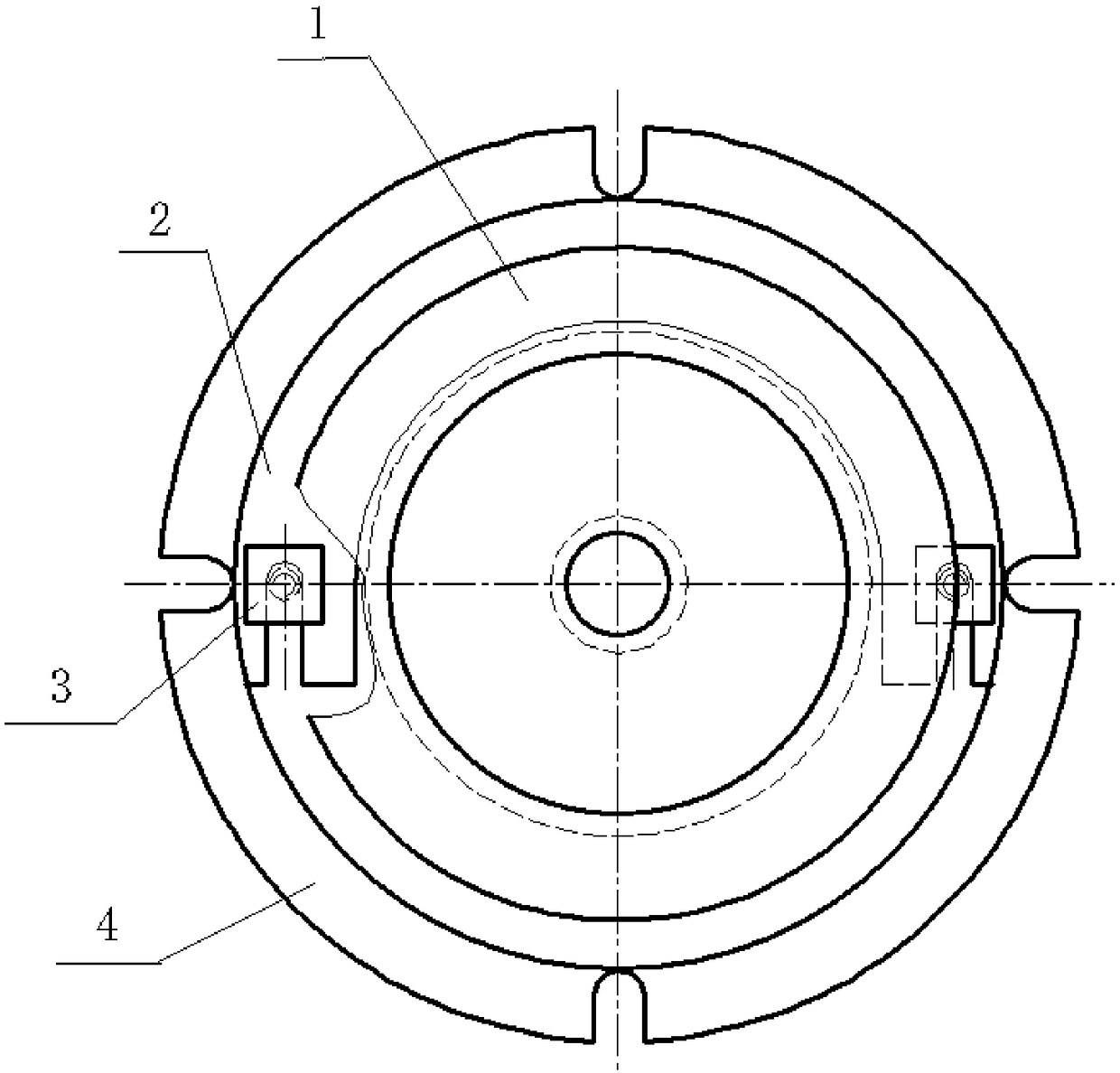

[0031] A quick-change air valve hot forging die, comprising a quick-change forging die, a U-shaped washer, a die base, and two screws.

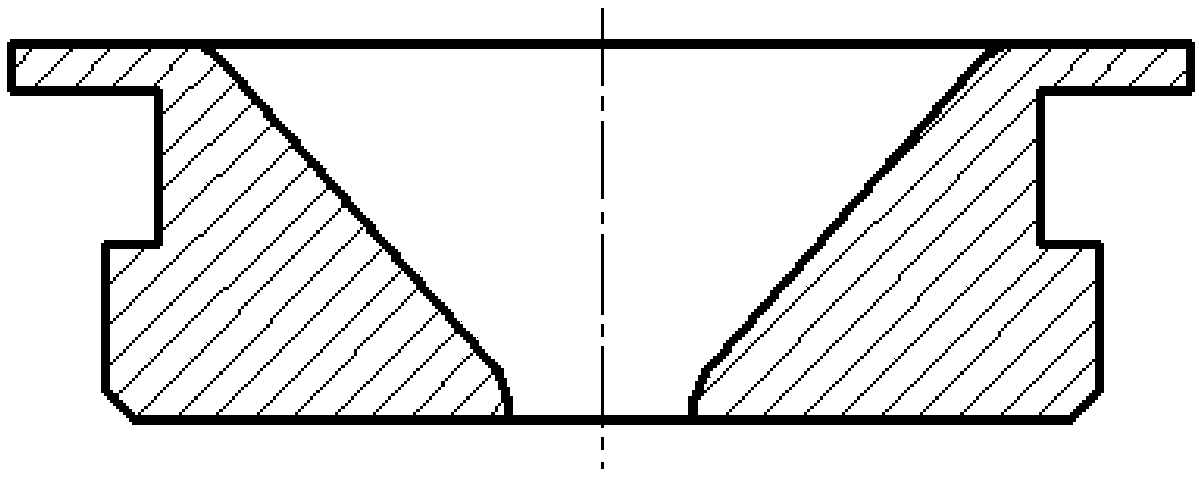

[0032] The inner cavity of the quick-change forging die corresponds to the shape of the valve, and different quick-change forging dies can be configured according to different valve models. When it is necessary to replace due to thermal fatigue, replace the quick-change forging die, and replace another type of quick-change forging die when producing different valves. The side wall of the quick-change forging die is convex, concave and convex, the upper surface of the concave structure is the lower surface of the convex structure, and the lower surface of the concave structure is the upper surface of the convex structure; when loading the mold, The tightened screw fixes the U-shaped washer on the mold base, and the U-shaped washer bears against the upper surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com