Design method applied to car frame assembly structure of two-step urban passenger car

A design method and assembly structure technology, applied in the substructure, vehicle parts, transportation and packaging, etc., can solve the problem of low utilization rate of the passenger area of the low floor, etc., achieve the weight reduction of the frame, the reduction of the manufacturing cost, and the convenience of transportation in different places and the effect of assembling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

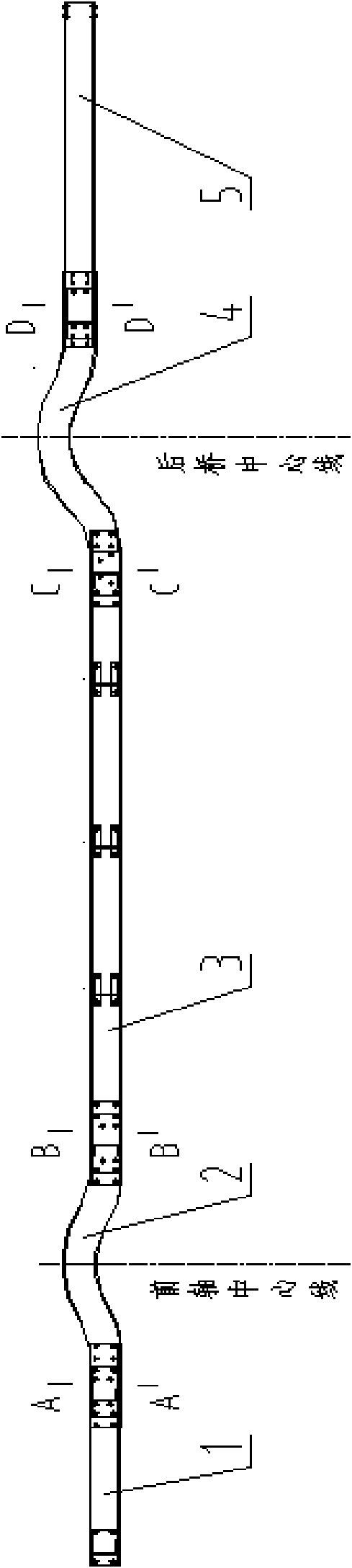

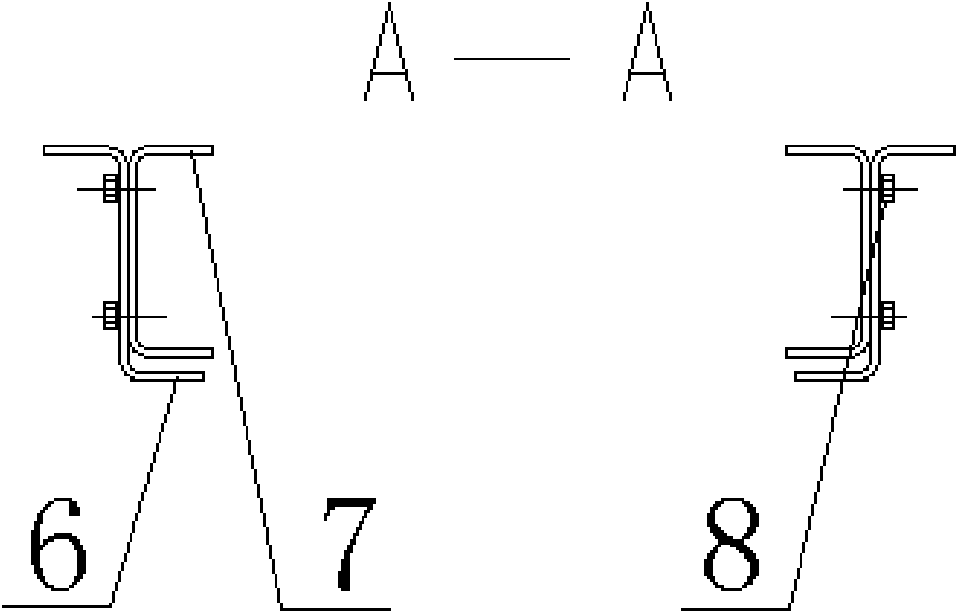

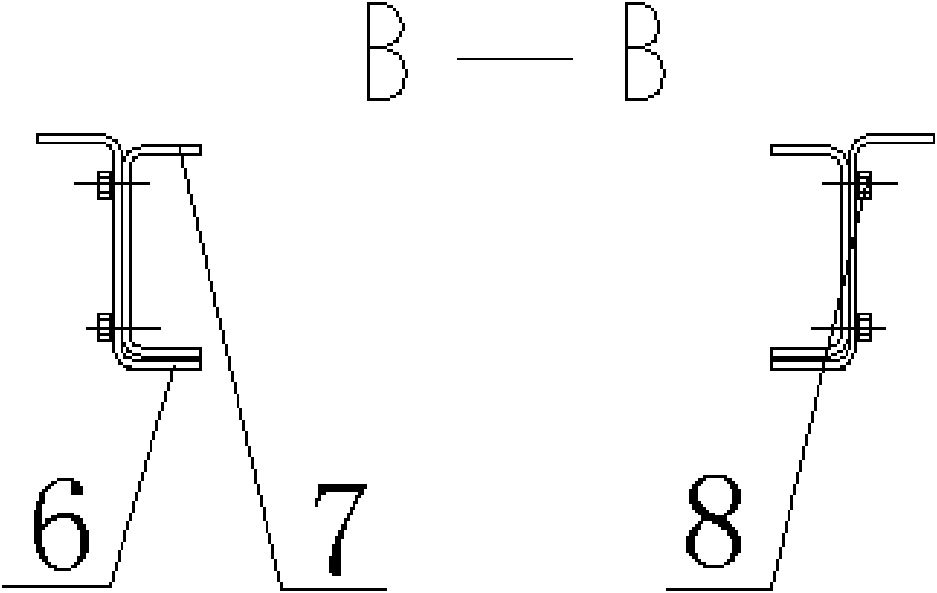

[0016] Such as figure 1 and Figure 6 As shown, it includes the front section frame module 1, the front axle frame module 2, the middle section frame module 3, the rear axle frame module 4, the rear section frame module 5, the front section frame module 1, the middle section frame module 3 and the rear section The longitudinal beams on both sides of the section frame module 5 have a "["-shaped structure, and the planes of the longitudinal beams on the front and rear sides of the front axle frame module 2 are connected to the longitudinal beams on both sides of the front section frame module 1 and the middle section frame module 3 respectively. The plane of the "shaped structure is connected by a bolt and nut structure 8; the planes of the longitudinal beams on the front and rear sides of the rear axle frame module 4 and the longitudinal beams on both sides of the middle frame module 3 and the rear frame module 5 are planes of a "[" shaped structure respectively. Connected by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com