Direct stored energy control system of plasma-cutting power source and control method thereof

A technology of energy storage control and plasma, applied in plasma welding equipment, electrical components, manufacturing tools, etc., can solve the problems of large cutting current ripple, low frequency oscillation cost, poor cutting quality, etc., to reduce the harm of harmonic current, Low cutting current, increasing real-time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

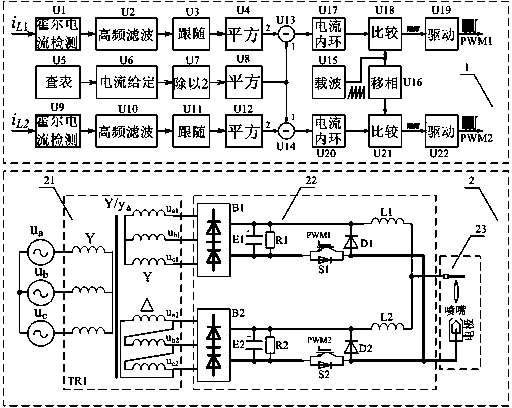

[0026] see figure 1 , the present invention relates to a direct energy storage control system for plasma cutting power supply, said system includes a power circuit 2 and a control circuit 1;

[0027] The power circuit includes a reducing circuit 21, a chopper circuit 22 and a cutting torch circuit 23. The step-down circuit is a power frequency transformer, and the power frequency transformer includes a star-connected (Y-connected) primary coil, a star The secondary coil of the star connection (Y connection) and the secondary coil of the delta connection (△ connection), and the primary coil of the star connection input 380V three-phase AC power supply, the secondary coil of the star connection and the secondary coil of the delta connection The initial phases of the primary coils are 0° and 30° respectively, and the output voltage is 220V;

[0028] The chopper circuit includes a first interleaved BUCK circuit and a second interleaved BUCK circuit;

[0029]The first interleaved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com