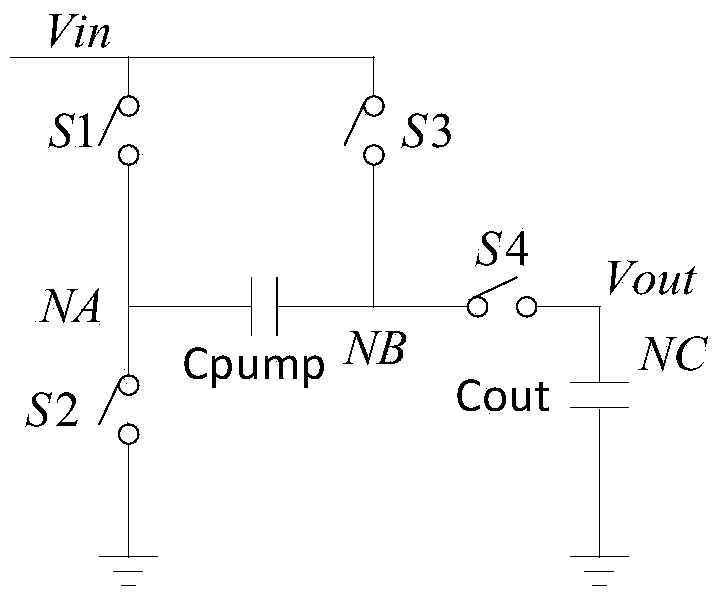

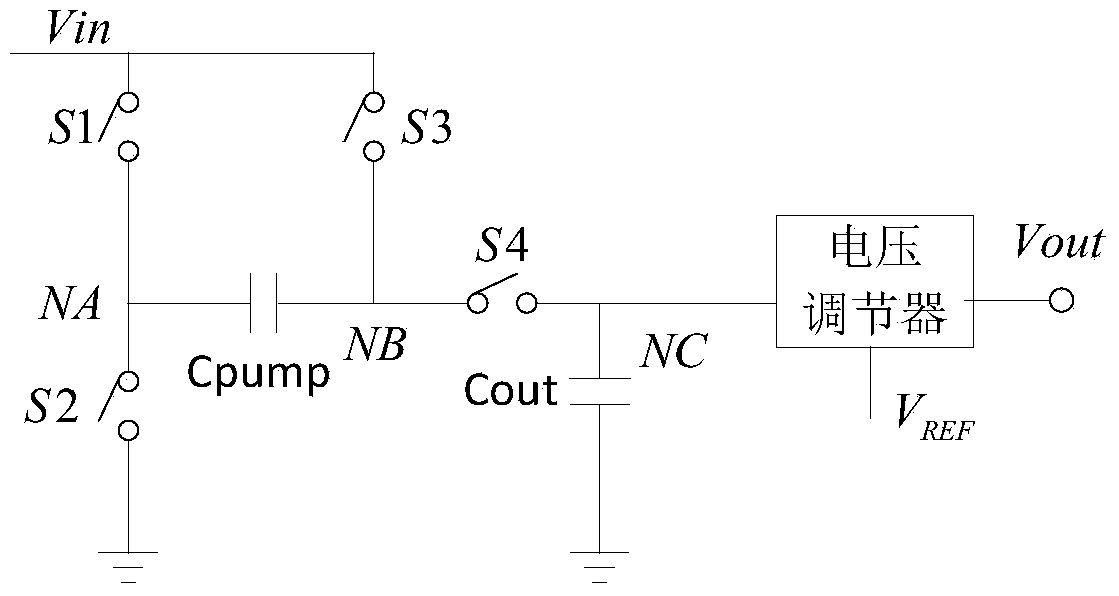

Boost charge pump circuit

A charge pump and circuit technology, which is applied in the direction of motor generator control, electrical components, sustainable manufacturing/processing, etc., can solve the problems of voltage regulator conversion efficiency drop, waste of energy, and charge pumps are difficult to meet, and achieve improved circuit conversion. Efficiency, differential stability, and power saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The foregoing and other objects, features, and advantages of the present invention will be more apparent from the following description and accompanying drawings. Here, specific embodiments according to the present invention will be described in detail with reference to the accompanying drawings.

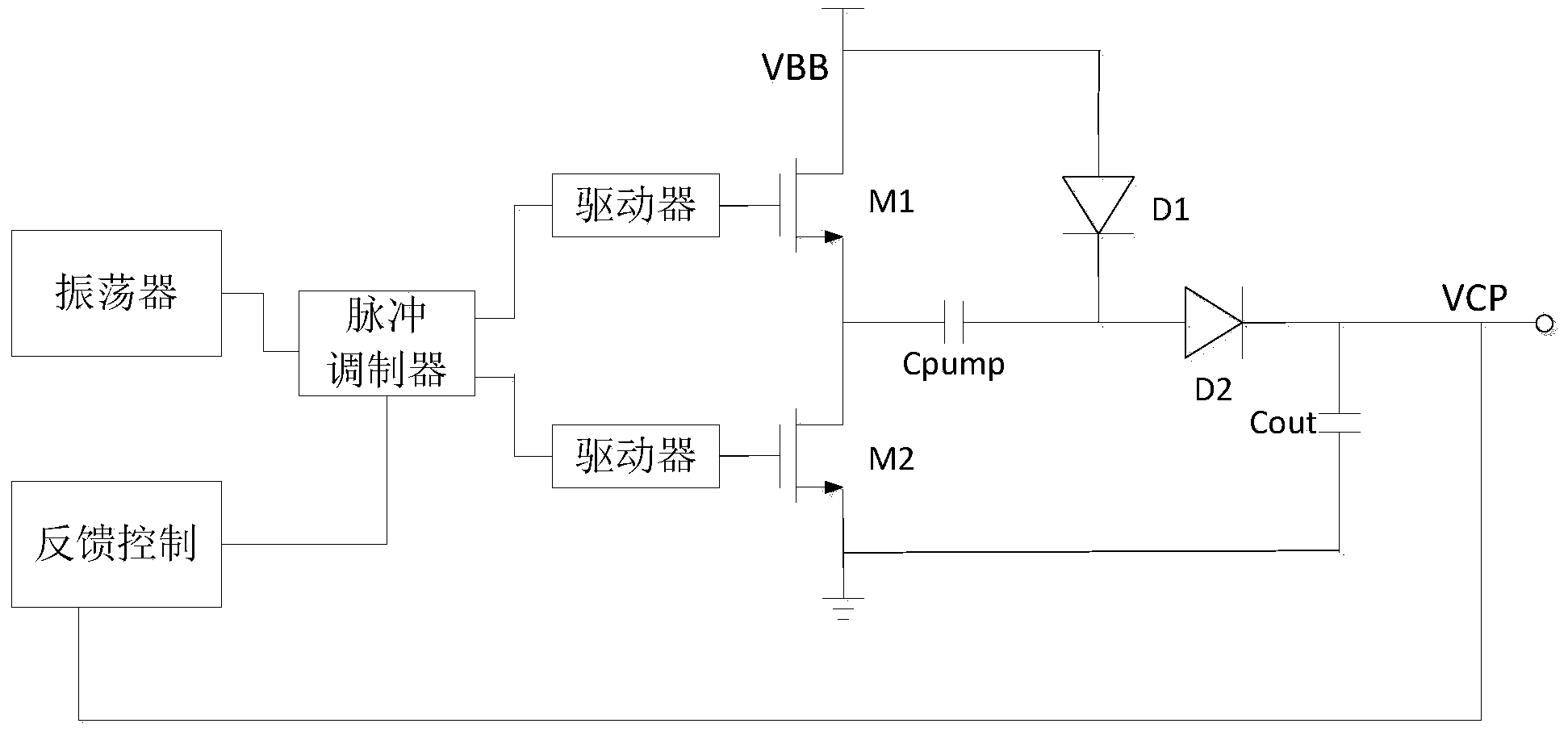

[0035] Such as image 3 As shown, the charge pump circuit of an embodiment of the present invention includes an output terminal Vout, a pair of NMOS switch tubes M1, M2, a pair of diodes D1, D2, a pump capacitor Cpump and a charging capacitor Cout, and the NMOS switch tubes M1, M2 and Diodes D1 and D2 form an H-bridge structure, the pump capacitor Cpump is connected between the source of the NMOS switch M1 and the cathode of the diode D1, and the charging capacitor Cout is connected between the cathode of the diode D2 and the ground;

[0036] The charge pump circuit in this embodiment also includes an oscillator, a pulse modulator, a first driver, a second driver, and a feed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com