Parallel device based on Delta mechanism and 3D printer adopting same

A parallel and motion mechanism technology, applied in the field of 3D printing, can solve the problems of complex design, small working space, transmission failure, etc., and achieve the effect of improving the narrow motion space, convenient later maintenance, and simplifying the control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

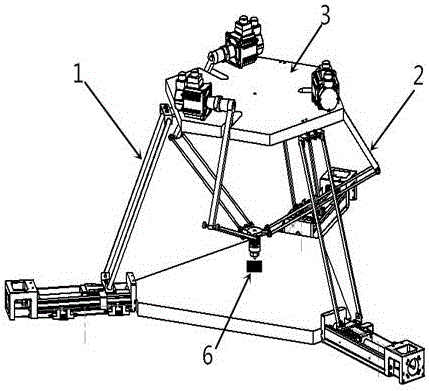

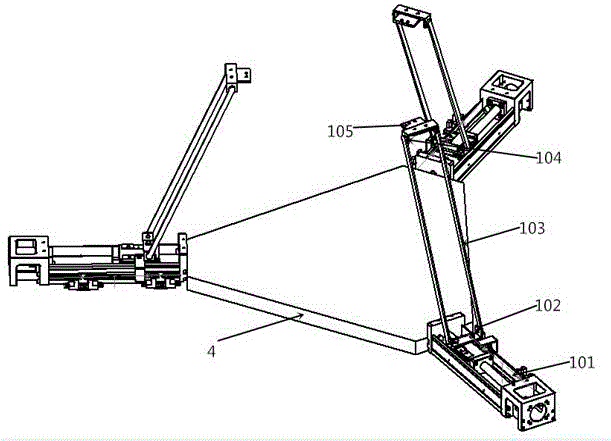

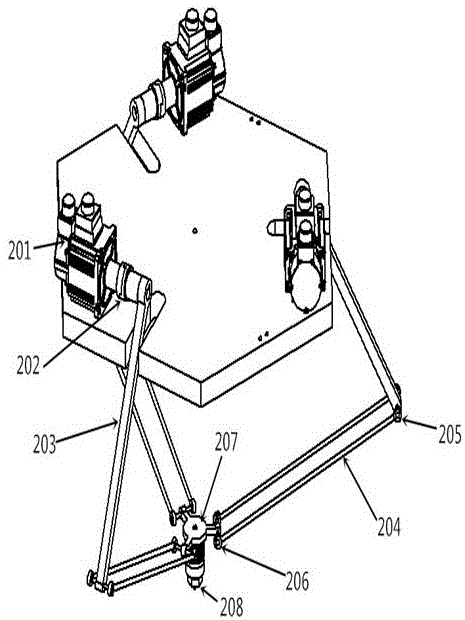

[0058] see figure 1 , 2 and 3, further, typical embodiments of the invention are:

[0059] Between the main bearing platform 3 and the supporting platform 4, there are three sets of primary motion mechanisms 1. The three sets of primary motion mechanisms 1 are distributed in a character shape. Three sets of first-level kinematic mechanisms 1 together form a PUU kinematic chain structure. Wherein, each primary motion mechanism 1 includes a linear slide 101 , a support arm 103 , a support plate 105 , a third rod-end joint bearing 104 and a fourth rod-end joint bearing 102 .

[0060] The linear slide table 101 includes a slider and a drive motor. The drive motor in the linear slide table 101 drives the corresponding slider to move back and forth.

[0061] The top of the support arm 103 is connected to the support plate 105 through the third rod-end joint bearing 104 , and the support plate 105 is connected to the main platform 3 .

[0062] The bottom of the support arm 103 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com