Automatic loading and unloading device of numerical control honing machine

A technology of automatic loading and unloading, grinding machine, applied in the direction of grinding machine parts, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of manual loading and unloading, low degree of use, etc., to achieve safe and reliable work, easy to operate , the effect of good control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

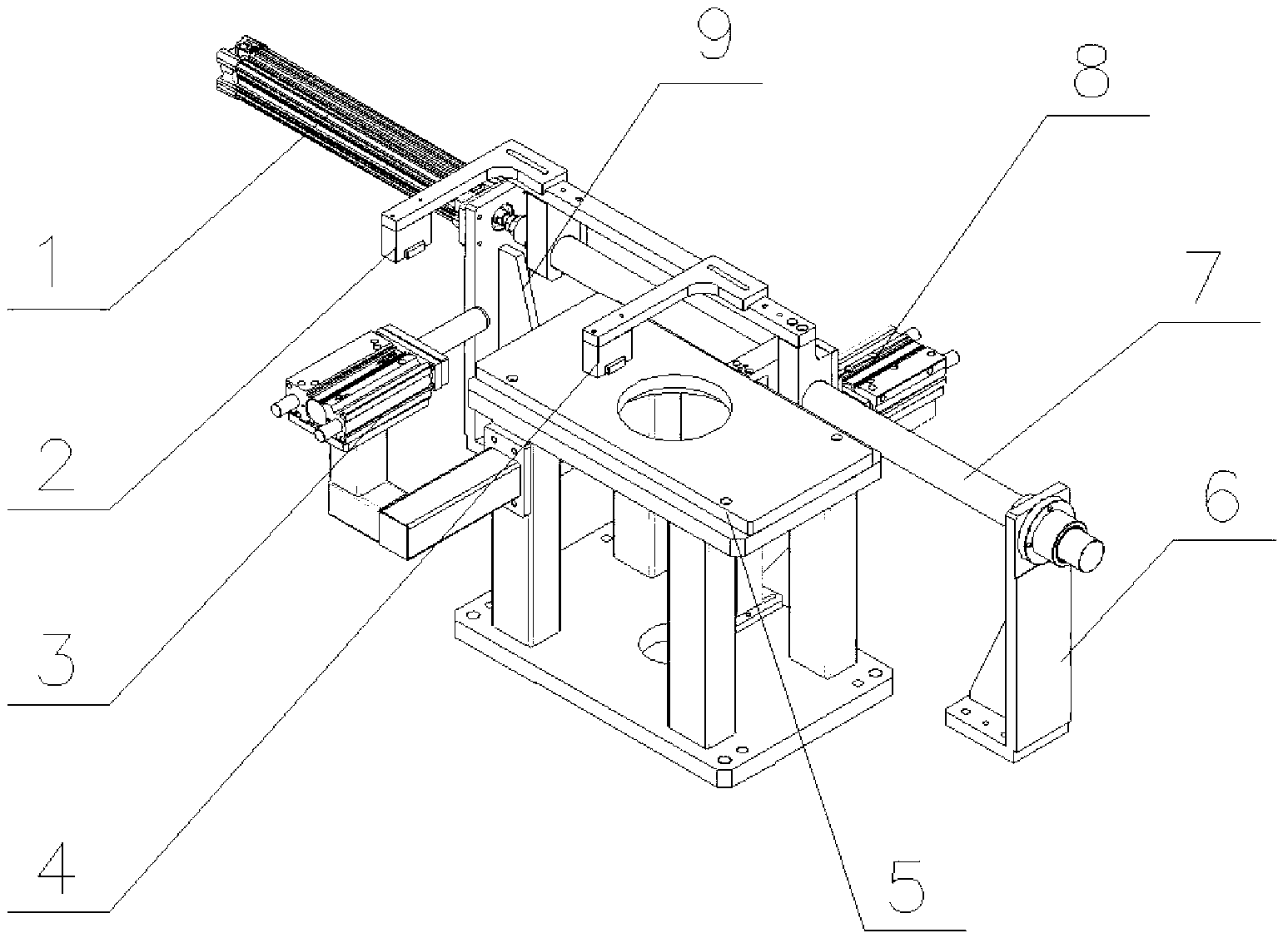

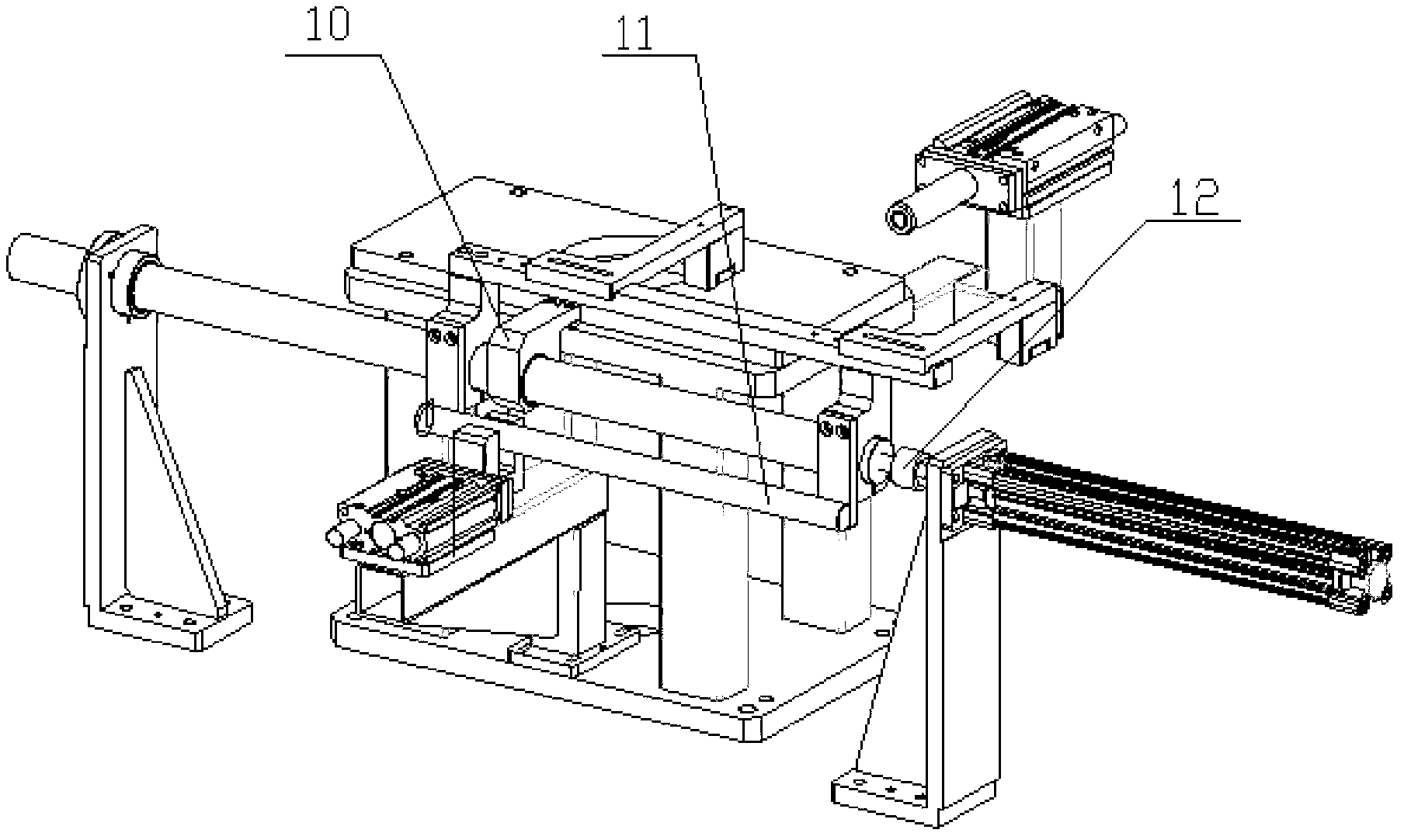

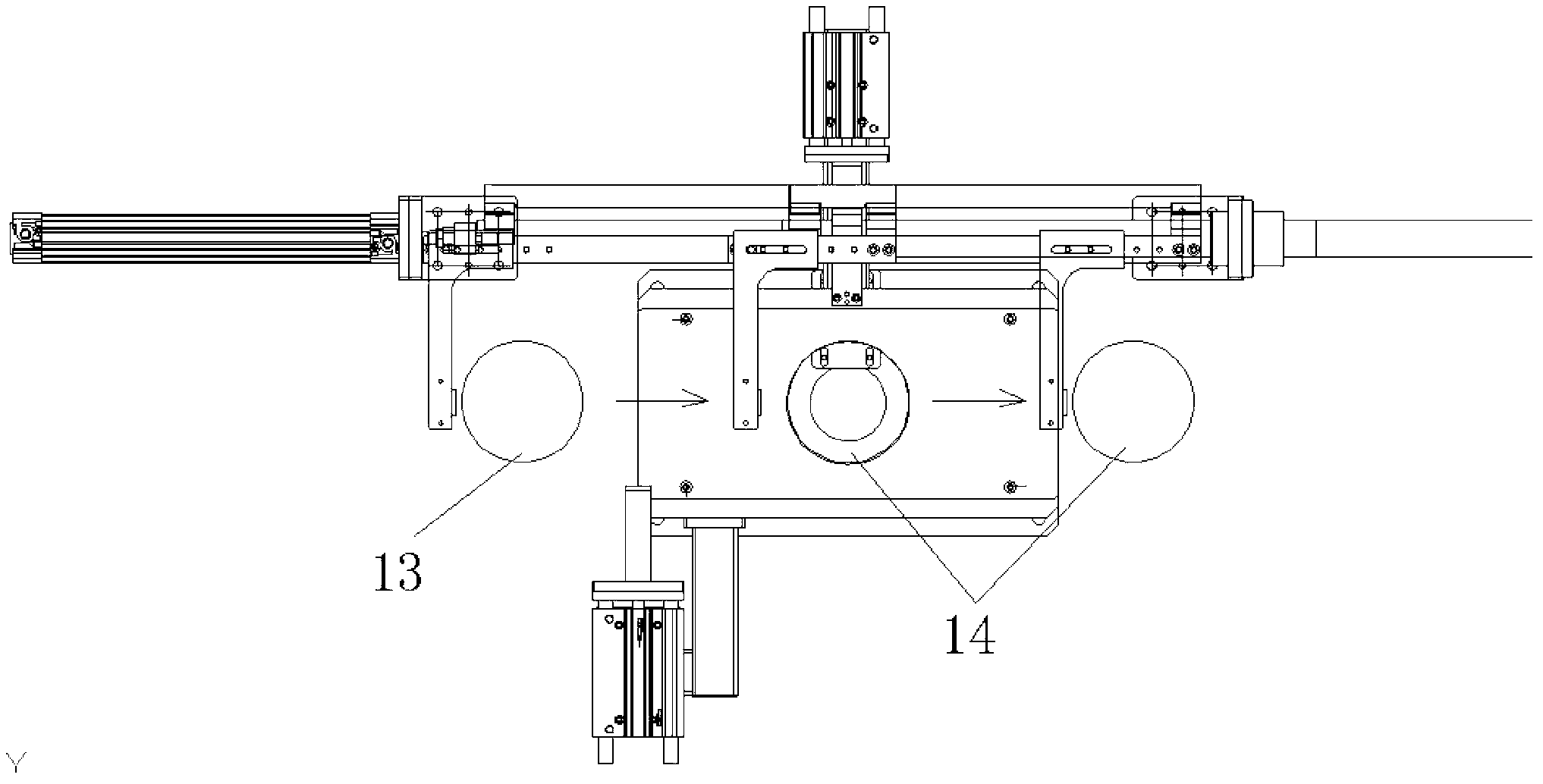

[0014] Such as figure 1 , 2 , 3, the present invention is an automatic loading and unloading device for a numerically controlled truss mill, comprising an optical axis 7, and the two ends of the optical axis 7 are installed on the middle auxiliary support seat 10 and the right auxiliary support seat 6 respectively, and the optical axis 7 and the middle auxiliary support seat 10 and the right auxiliary support seat 6 are clearance fit, that is, the optical axis 7 can move or rotate within the range of these two support seats, and the middle auxiliary support seat 10 is fixed on the workbench 5 .

[0015] On the optical axis 7, there are respectively fixedly installed a loading toggle 2 and a blanking toggle 4, and the loading toggle 2 and the unloading toggle 4 are rigidly connected together by a connecting shaft 11, that is, the loading toggle 2. The feeding head 4 and the connecting shaft 11 move synchronously with the optical axis 7. Also comprise pusher mechanism 1, this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com