Separation and recovery device and method for argon and methane in synthetic ammonia relief gas

A technology for degassing, separation and recovery of synthetic ammonia, applied in the direction of cold treatment separation, chemical instruments and methods, inert gas compounds, etc., can solve the problem that argon and methane cannot be separated and purified, and reduce the loss of effective energy and reduce the energy consumption of the device , High recovery effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

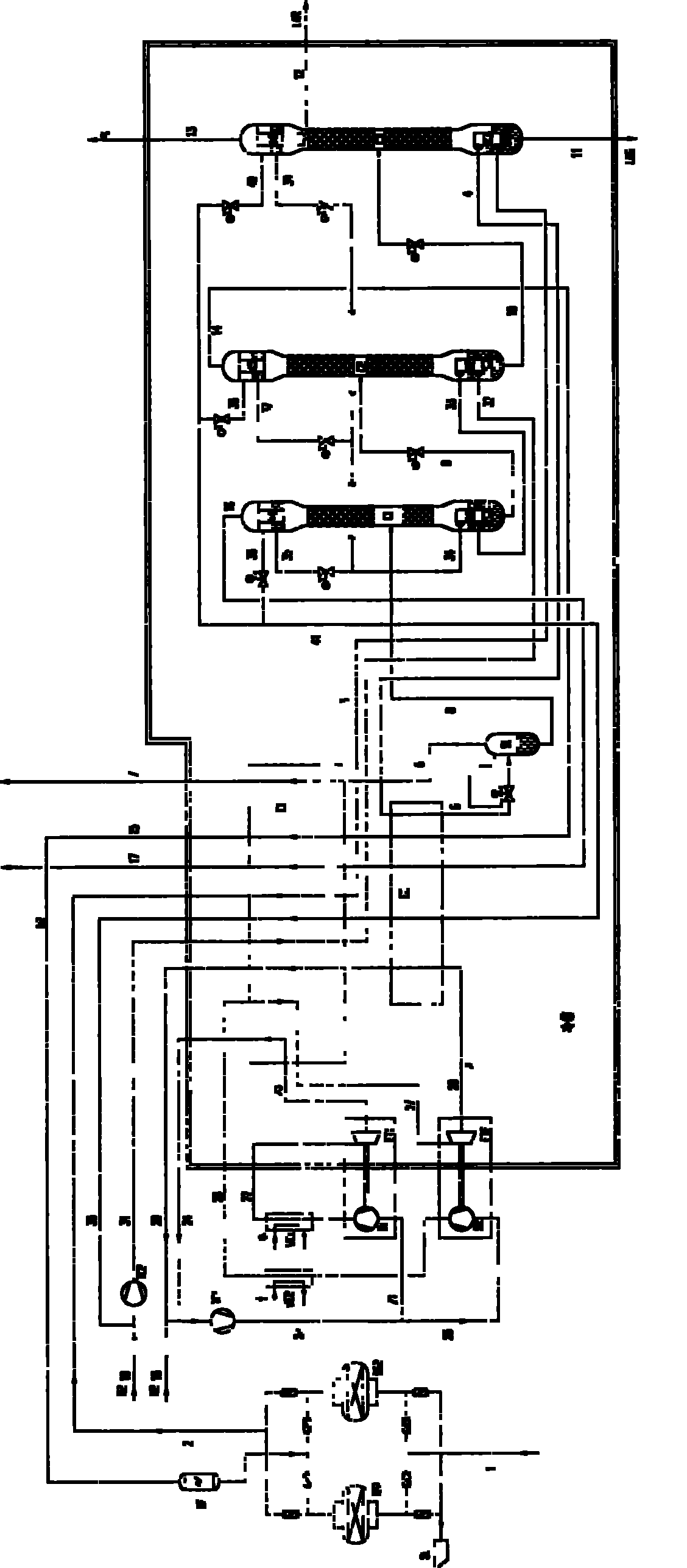

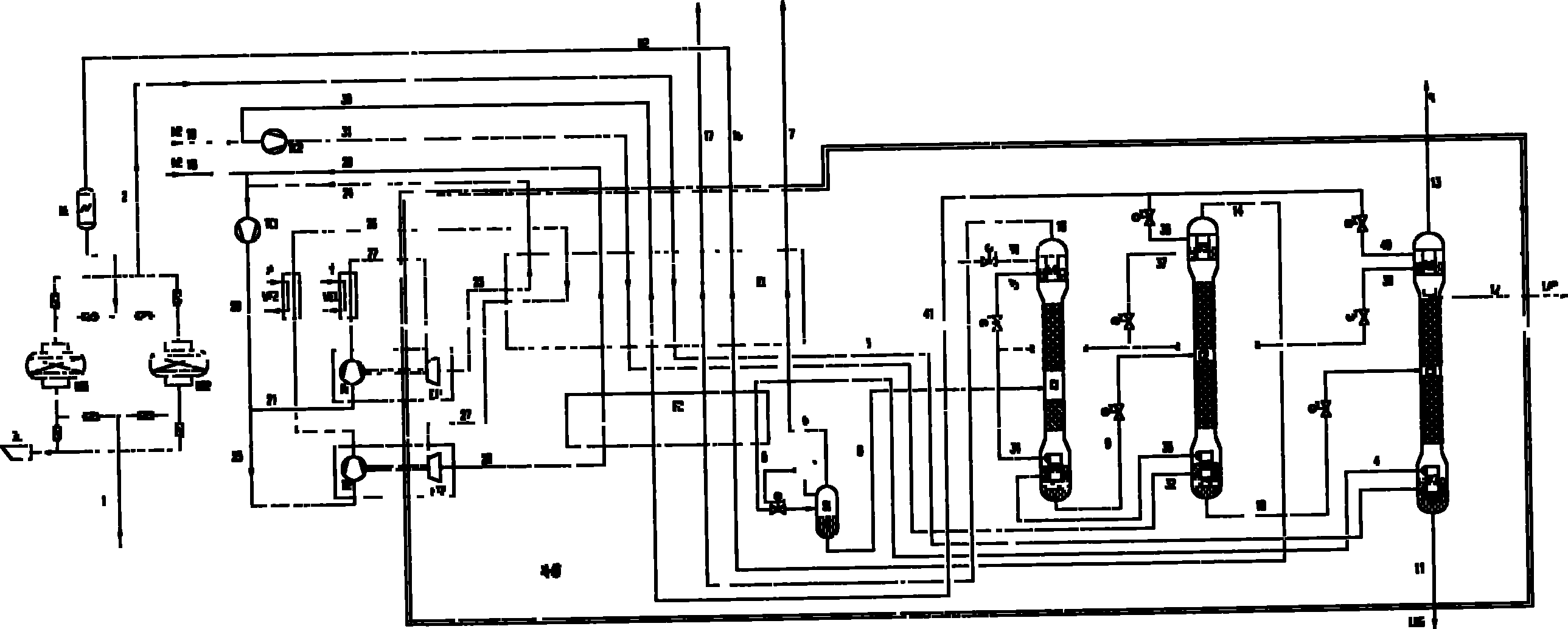

[0024] Such as figure 1 As shown, a separation and recovery device for argon and methane in synthetic ammonia purge gas includes a cold box, a raw material purge gas pipeline 1, and a first molecular sieve adsorber MS1 and a second molecular sieve adsorber MS1 connected to the raw material purge gas pipeline 1 The purification system of molecular sieve adsorber MS2, the refrigeration system that provides the cooling capacity required for separation and liquefaction, and the rectification system that separates the purge gas of raw materials step by step. The refrigeration system includes low-pressure circulating nitrogen compressor TC1, medium-pressure circulating nitrogen compressor TC2, low-temperature supercharged turboexpander ET2, high-temperature supercharged turboexpander ET1, main heat exchanger E1, liquefier E2, external nitrogen is connected to low-pressure circulating nitrogen compressor TC1 through pipelines, and low-pressure circulating nitrogen compressor TC1 is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com