Low-concentration DMF wastewater treatment system by distillation method with multiple intermediate heat exchangers

An intermediate heat exchanger, low-concentration technology, applied in the direction of heating water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problems of low thermodynamic efficiency and energy waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

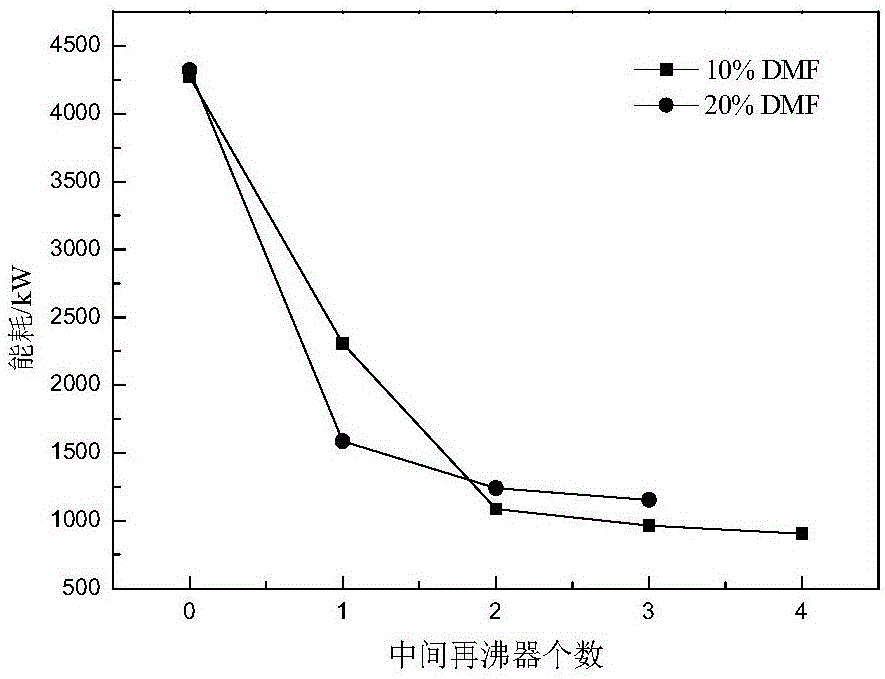

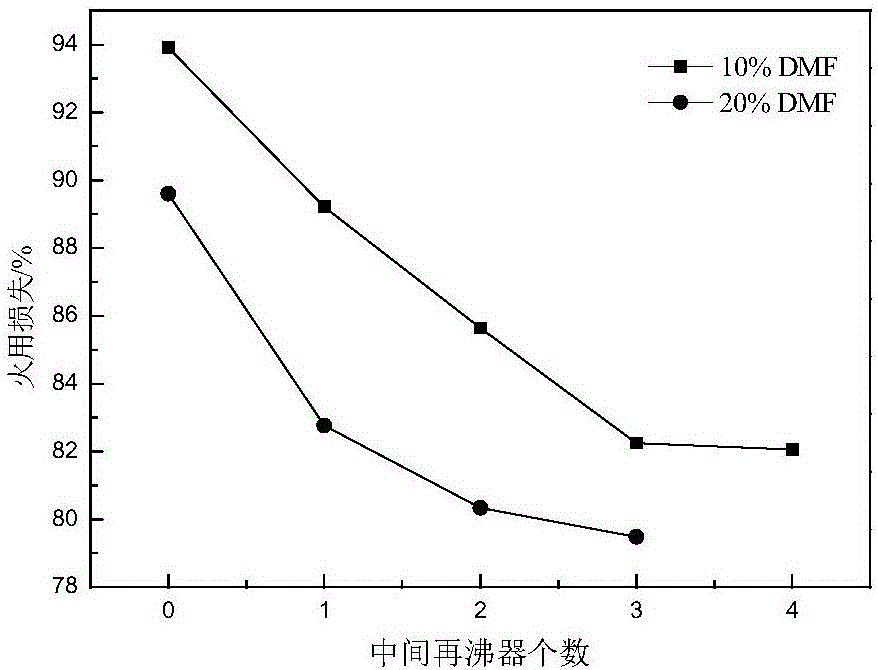

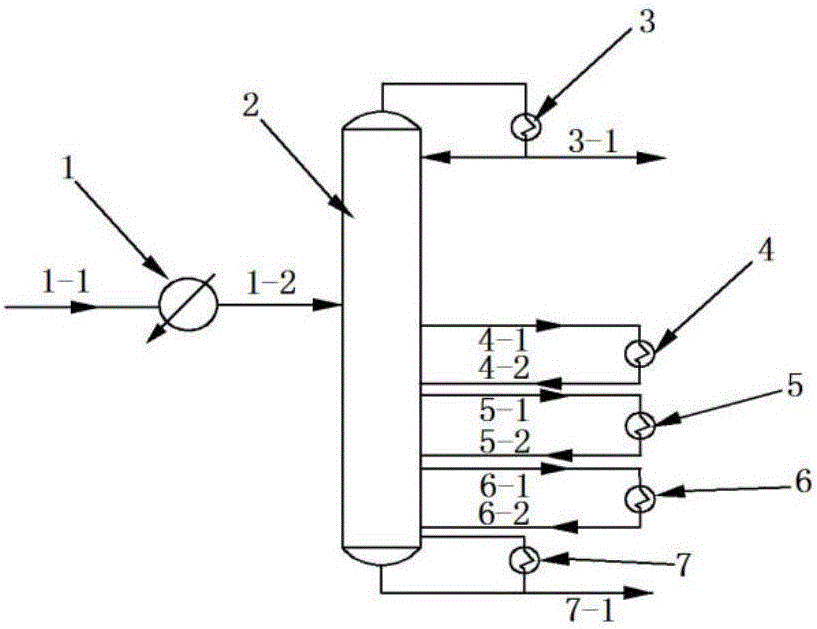

[0028] Attached image 3 Shown technological process, contain DMF 10% (massfraction) in the raw material mixture A, H 2 O90% (mass fraction), feed rate is 5000kg / h, enters preheater 1 preheating under normal temperature and pressure, enters separation in rectifying tower 2 by 102 after reaching bubble point temperature. The DMF wastewater separation and rectification tower needs 42 theoretical plates, the operating pressure is 0.1 MPa, the packing used is corrugated packing with perforated plates, the tower diameter is 1.15 meters, and the reflux ratio is 0.44. The concentration of the water at the top of the tower reaches 99.8%, and the DMF product with a purity of 99.8% is obtained in the tower still. Extract 90% of the tray material total amount from 37 plates, that is, the mixture of 7705.1kg / h is extracted through the 401 pipeline, and the temperature of the material is 102.4 ° C. Through the intermediate heat exchanger 4 (heated with 0.17MPa steam), the consumption of 3...

Embodiment 2

[0031] Attached image 3 Shown technological process, contain DMF 20% (massfraction) in raw material mixture A, H 2O 80% (mass fraction), feed rate is 5000kg / h, enters preheater 1 preheating under normal temperature and pressure, enters separation in rectifying column 2 by S102 after reaching bubble point temperature. The DMF wastewater separation and rectification tower needs 28 theoretical plates, the operating pressure is 101.3kPa, the packing used is corrugated packing with perforated plates, the tower diameter is 1.1 meters, and the reflux ratio is 0.51. The concentration of the water at the top of the tower reaches 99.8%, and the DMF product with a purity of 99.8% is obtained in the tower still. Extract 30% of the tray material total amount from 21 plates, that is, the mixture of 3692.6kg / h is extracted through the 401 pipeline, the temperature of the material is 101.7°C, and through the intermediate heat exchanger 4 (heated with 0.17MPa steam), the consumption of 1638....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com