Non-azeotropic working medium dual-stage organic flash evaporation circulation system and heat energy recovery method thereof

A circulatory system and non-azeotropic technology, applied in steam recovery, mechanical equipment, steam engine devices, etc., to achieve effective utilization, improve temperature matching, and achieve high-efficiency utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

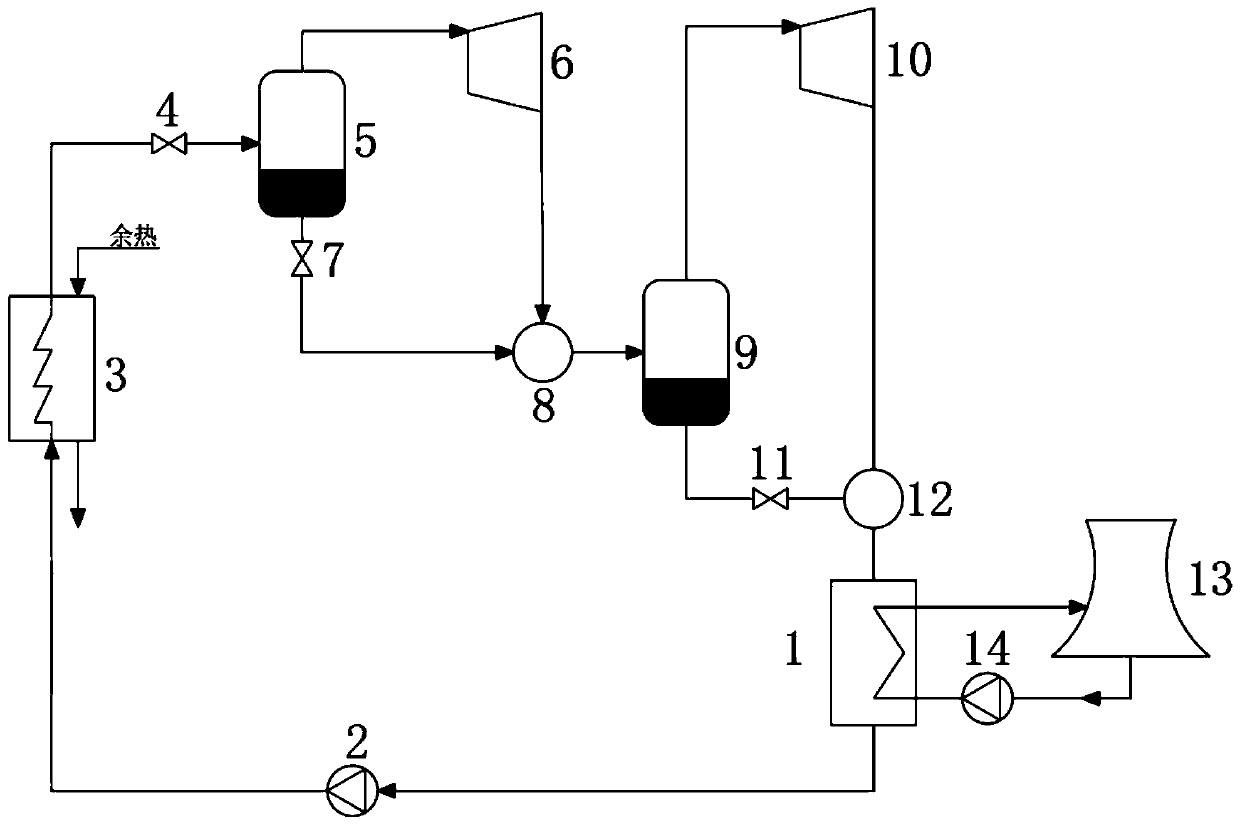

[0022] See attached figure 1 . A non-azeotropic working medium two-stage organic flash cycle system, including a condenser 1, a working medium pump 2, a heat exchanger 3, a first throttle valve 4, a high-pressure stage gas-liquid separator 5, and a high-pressure stage turbine 6 , high-pressure stage mixer 8, second throttle valve 7, low-pressure stage gas-liquid separator 9, low-pressure stage turbine 10, low-pressure stage mixer 12 and the third throttle valve 11; the thermal fluid side of the condenser 1 The outlet, the working medium pump 2 and the inlet of the cold fluid side of the heat exchanger 3 are sequentially connected through pipelines; the outlet of the cold fluid side of the heat exchanger 3, the first throttle valve 4 and the inlet of the high-pressure stage gas-liquid separator 5 Connect sequentially through pipelines; the steam outlet of the high-pressure stage gas-liquid separator 5 is connected with the inlet of the high-pressure stage turbine 6 through pip...

Embodiment 2

[0024] See attached figure 1 . A non-azeotropic working medium two-stage organic flash cycle system, including a condenser 1, a working medium pump 2, a heat exchanger 3, a first throttle valve 4, a high-pressure stage gas-liquid separator 5, and a high-pressure stage turbine 6 , high-pressure stage mixer 8, second throttle valve 7, low-pressure stage gas-liquid separator 9, low-pressure stage turbine 10, low-pressure stage mixer 12 and the third throttle valve 11; the thermal fluid side of the condenser 1 The outlet, the working medium pump 2 and the inlet of the cold fluid side of the heat exchanger 3 are sequentially connected through pipelines; the outlet of the cold fluid side of the heat exchanger 3, the first throttle valve 4 and the inlet of the high-pressure stage gas-liquid separator 5 Connect sequentially through pipelines; the steam outlet of the high-pressure stage gas-liquid separator 5 is connected with the inlet of the high-pressure stage turbine 6 through pip...

Embodiment 3

[0031] See attached figure 1 . A method for recovering heat energy of a non-azeotropic working medium two-stage organic flash cycle system, using the above-mentioned non-azeotropic working medium two-stage organic flash cycle system, including a waste heat absorption step, a heat energy utilization step and a working medium Cooling step; the step of absorbing waste heat is specifically: the working fluid comes out from the hot fluid side outlet of the condenser 1, and enters the cold fluid side inlet of the heat exchanger 3 after being pressurized by the working fluid pump 2, and the working fluid is in the heat exchanger 3 and The waste heat medium input from the hot fluid side inlet of the heat exchanger 3 and output from the hot fluid side outlet of the heat exchanger 3 is heat-exchanged; the heat energy utilization steps are as follows: the working fluid comes out from the cold fluid side outlet of the heat exchanger 3, passes through After throttling by the first throttl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com