Sludge drying device and method

A sludge drying and sludge technology, applied in the direction of sludge treatment through temperature control, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of waste of useful sludge resources, environmental pollution, etc., to improve heat exchange efficiency, The effect of prolonging the residence time and enhancing the heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A sludge drying device includes a housing, an intermediate sleeve, a central shaft and a driving mechanism; the central shaft is sleeved in the intermediate sleeve, and the outer wall of the central shaft and the inner wall of the intermediate sleeve form a first cavity. Both ends of the first cavity are respectively provided with a first inlet and a first outlet; the intermediate sleeve is sleeved in the housing, the outer wall of the intermediate sleeve and the inner wall of the housing form a second cavity, and both ends of the housing are respectively provided with a first Two inlets and a second outlet; the outer wall of the central shaft is provided with a spiral-shaped first partition along the axial direction of the central axis, and the outer wall of the intermediate sleeve is provided with a spiral-shaped second partition along the axial direction of the intermediate sleeve; The driving mechanism drives the intermediate sleeve to rotate along its axial direction...

Embodiment 2

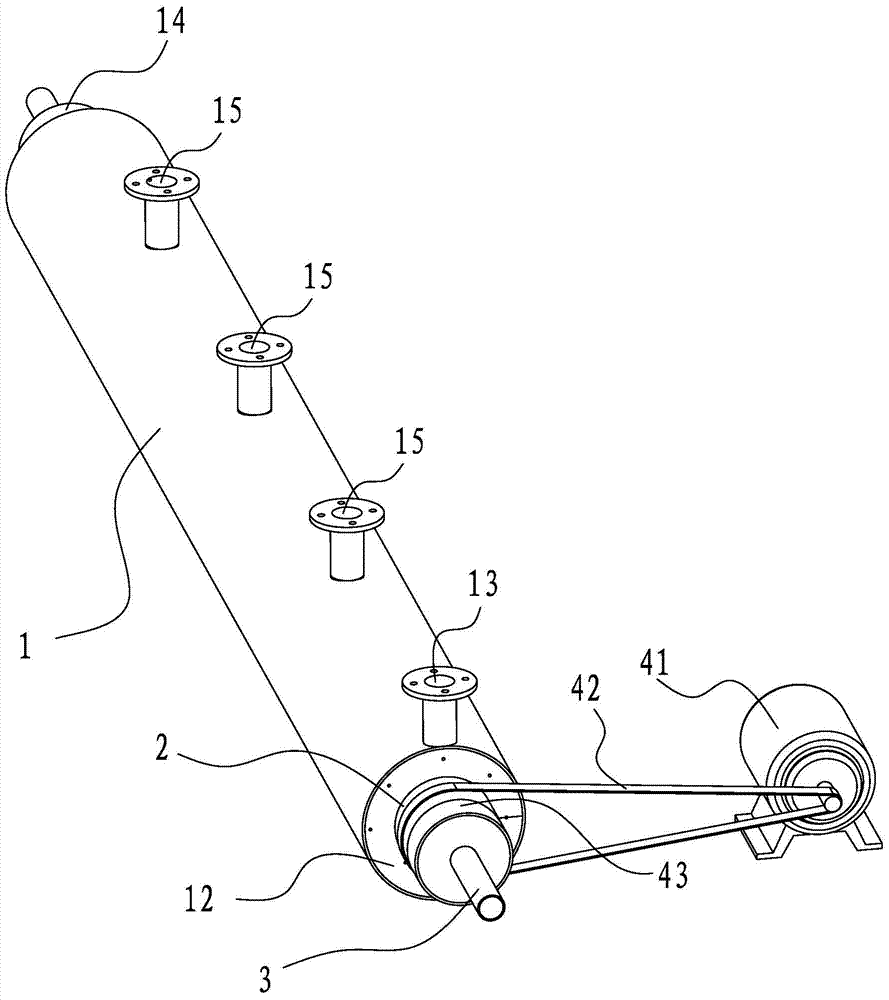

[0041] A sludge drying device, such as figure 1 As shown, it includes a housing 1, an intermediate sleeve 2, a central shaft 3 and a driving mechanism.

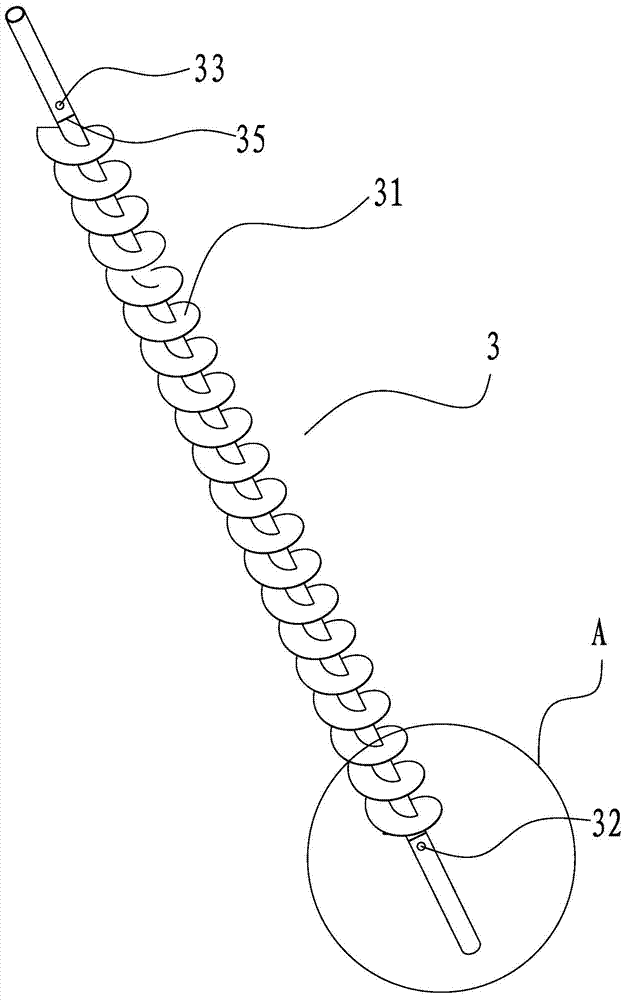

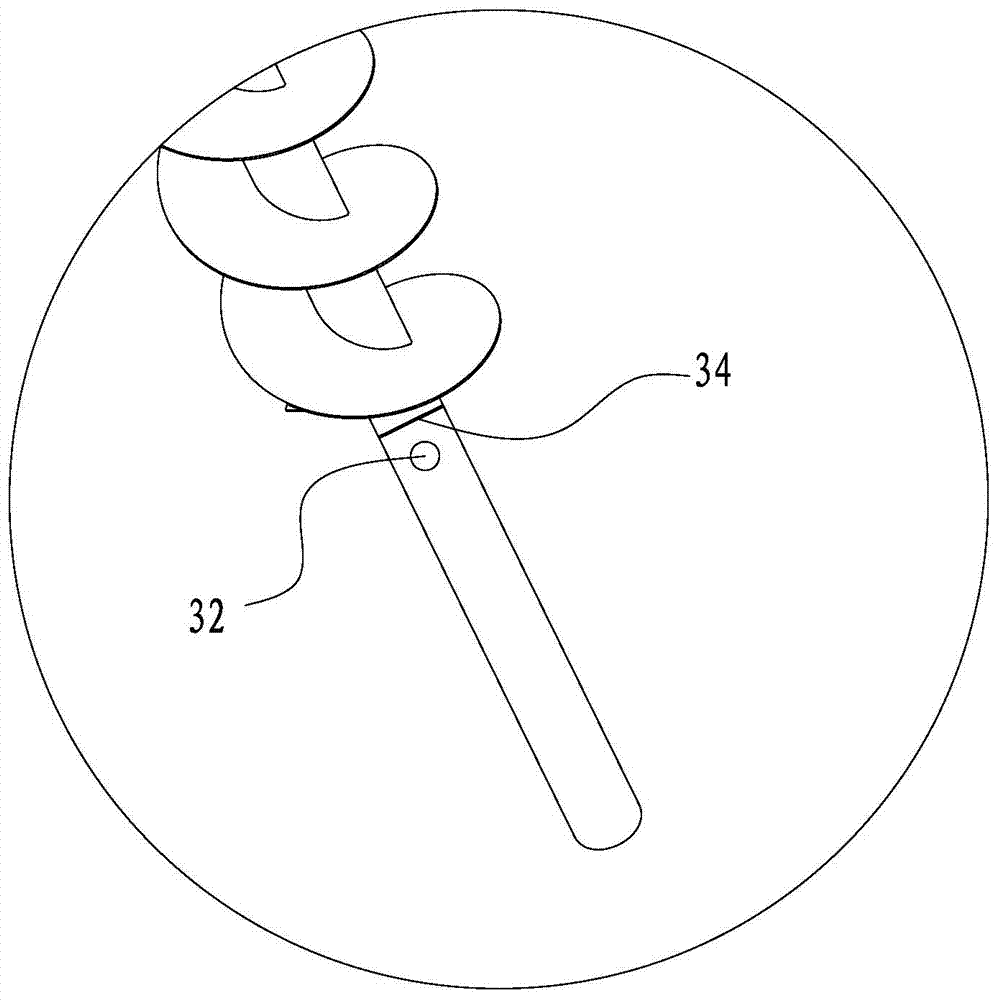

[0042] The central shaft 3 is sleeved in the intermediate sleeve 2 through a bearing 43. The outer wall of the central shaft 3 and the inner wall of the intermediate sleeve 2 form a first cavity. Both ends of the first cavity are respectively provided with first inlets and The first outlet; the intermediate sleeve 2 is sleeved in the housing 1, the housing 1 is provided with an outer end plate 12, the outer wall of the intermediate sleeve 2 and the housing 1 provided with the outer end plate 12 form a second cavity, The two ends of the housing 1 are respectively provided with a second inlet 13 and a second outlet 14; the outer wall of the central shaft 3 is provided with a spiral-shaped first partition 31 along the axial direction of the central shaft 3, such as figure 2 As shown, the outer wall of the intermediate sleeve 2 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com