Short-process comprehensive red mud utilization method and equipment

A short-flow, red mud technology, applied in red mud separation of iron, removal of aluminum-silicon slag and alkali metals, iron and refractory production technology fields, can solve environmental pollution, red mud stockpiles cannot be comprehensively utilized in large quantities, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

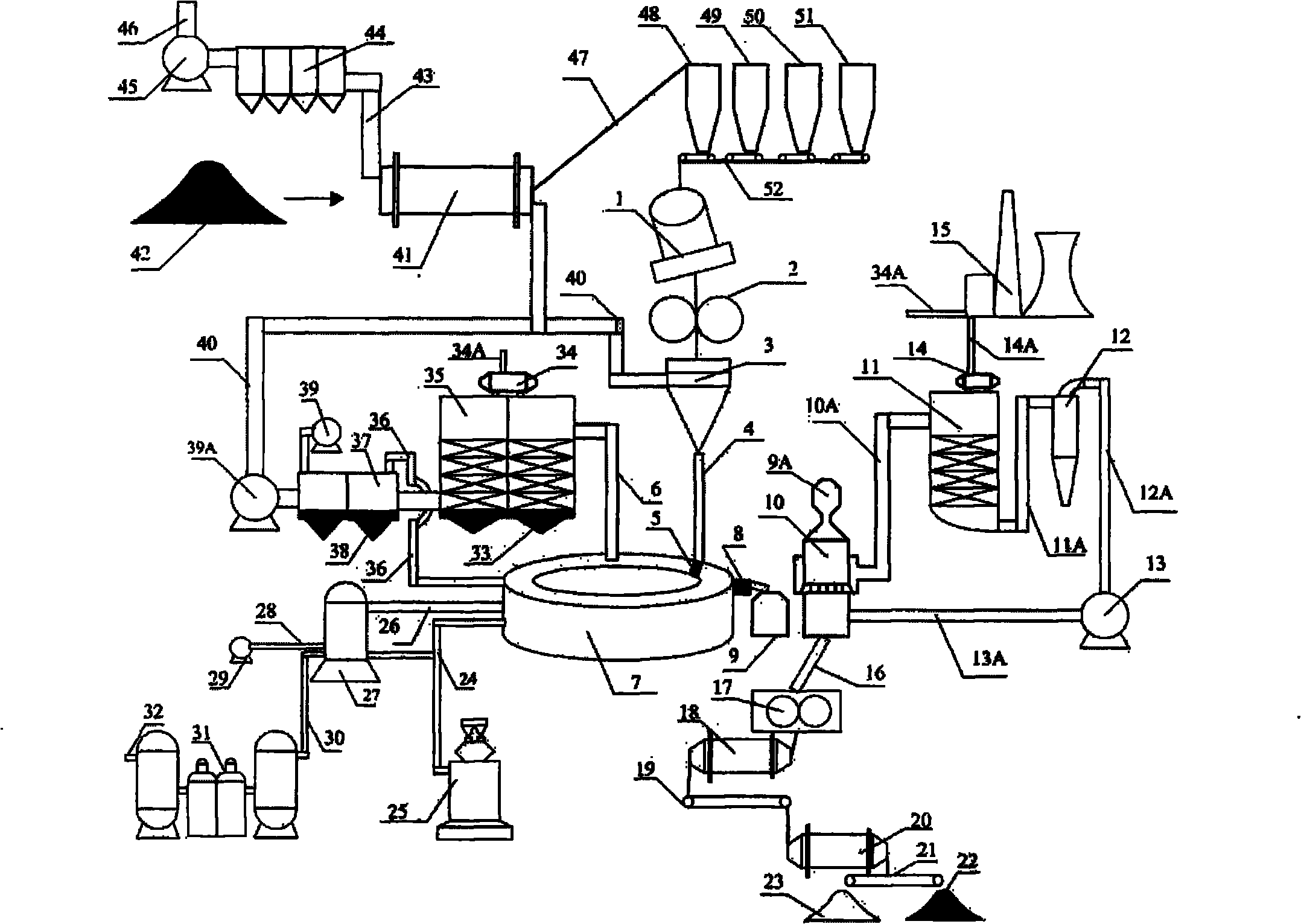

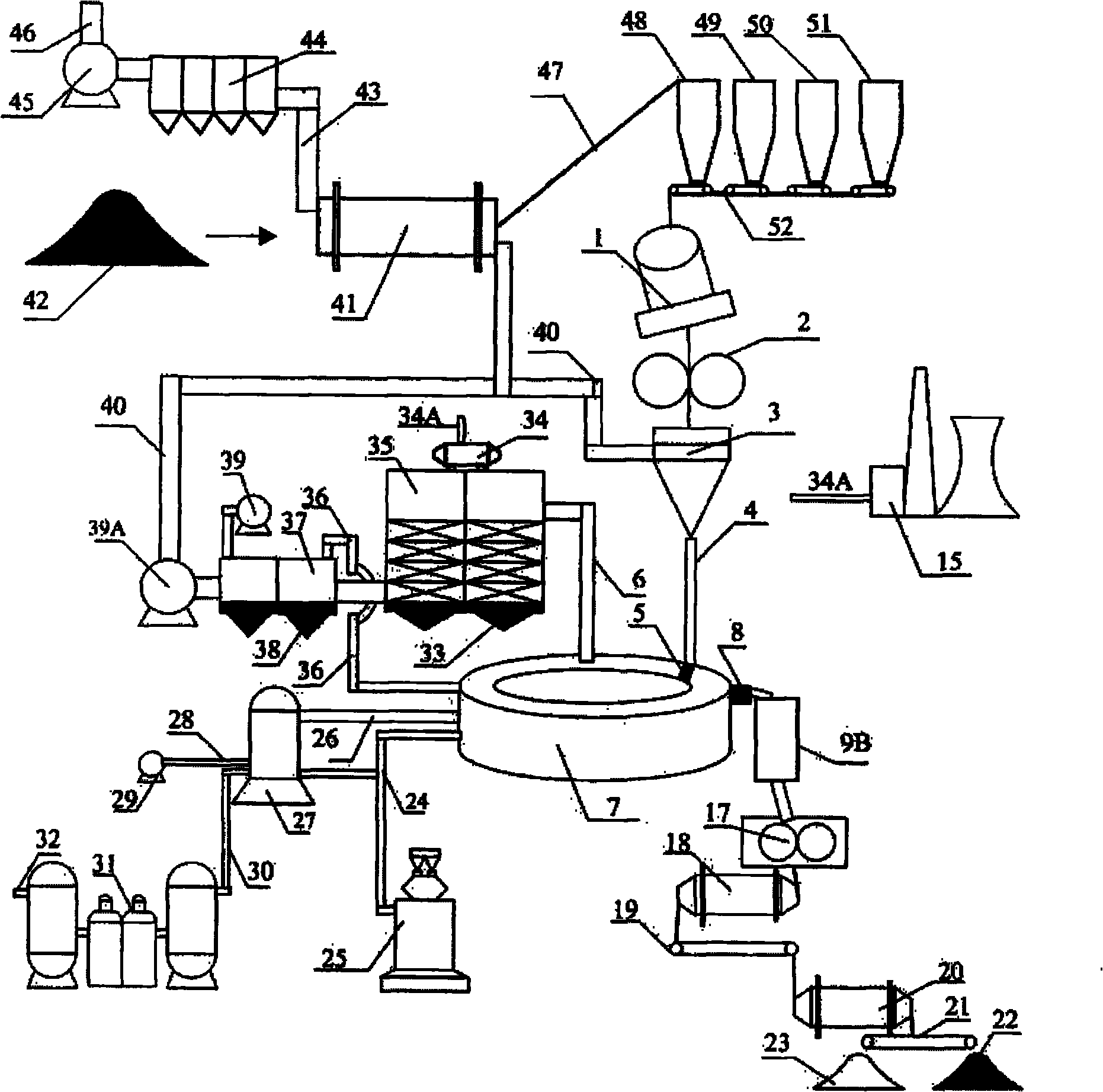

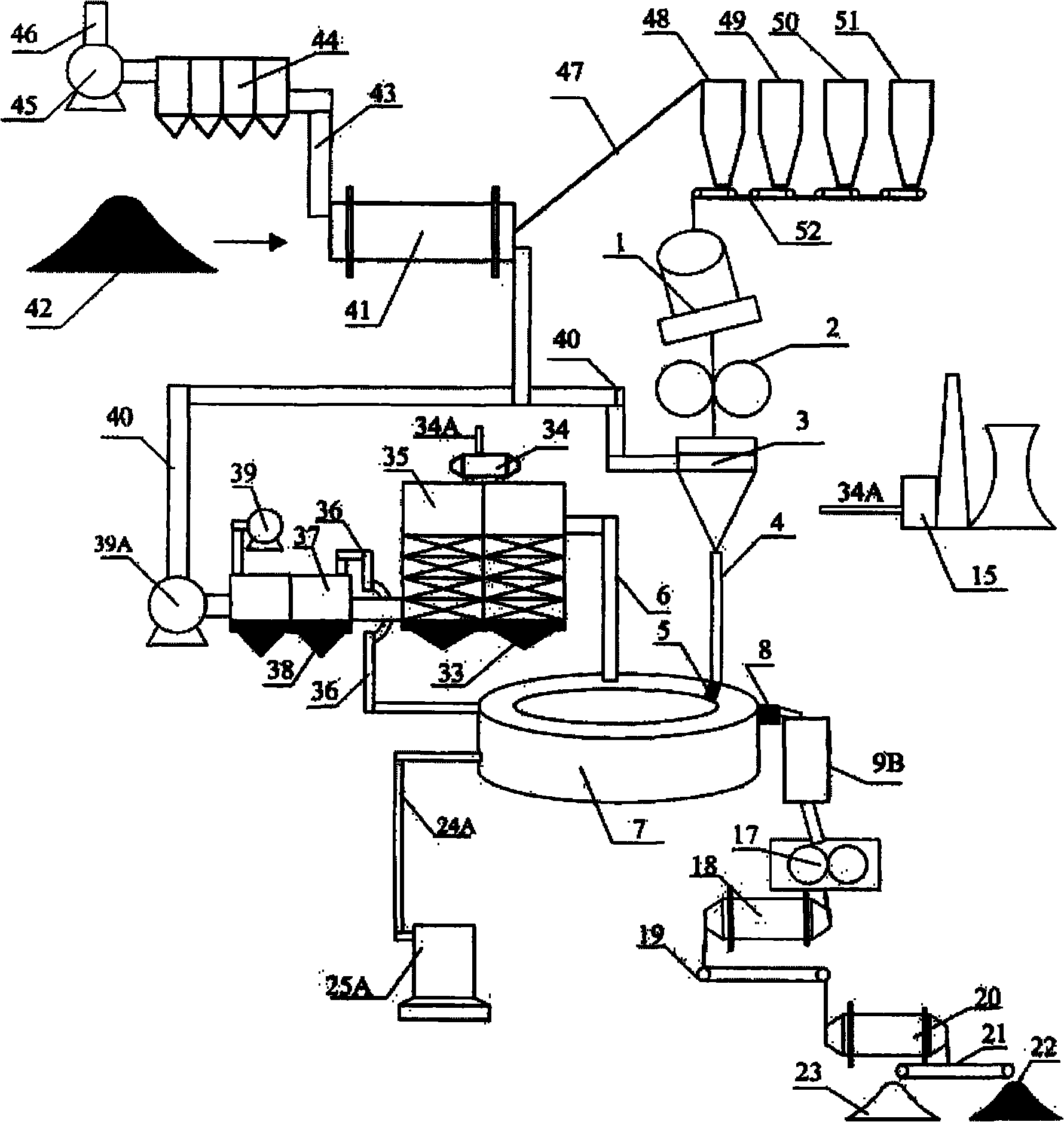

[0008] The present invention proposes a short-flow red mud comprehensive utilization method, comprising the following steps:

[0009] 1) After the red mud is dried, it is mixed with coal powder, lime and additives in a certain proportion, and processed into pellets;

[0010] 2) The pellets obtained in step 1) are preheated from flue gas at 300-350°C to 150-200°C in the preheating equipment and sent to the rotary bed;

[0011] 3) Rotating bed smelting reduction: In the rotating bed, the high-temperature oxygen-enriched hot air from the hot blast stove at 900-1100°C burns gas and carbon in the pellets to reduce Fe 2 o 3 The generated CO provides heat for the heating and melting reduction of the pellets. At a temperature of 1300-1500 ° C, the iron in the red mud is reduced and melted, and the molten iron particles gather into lump iron, making the pellets into molten reduction balls Agglomerates, so that iron and high-alumina-silicon slag are separated, and alkali metal oxides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com