Porcelain granule and preparation method thereof

A technology of ceramsite and materials, which is applied in the field of ceramsite and its preparation, can solve the problems of insufficient utilization of waste residue, etc., and achieve the effect of rich pores, high strength and good surface properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

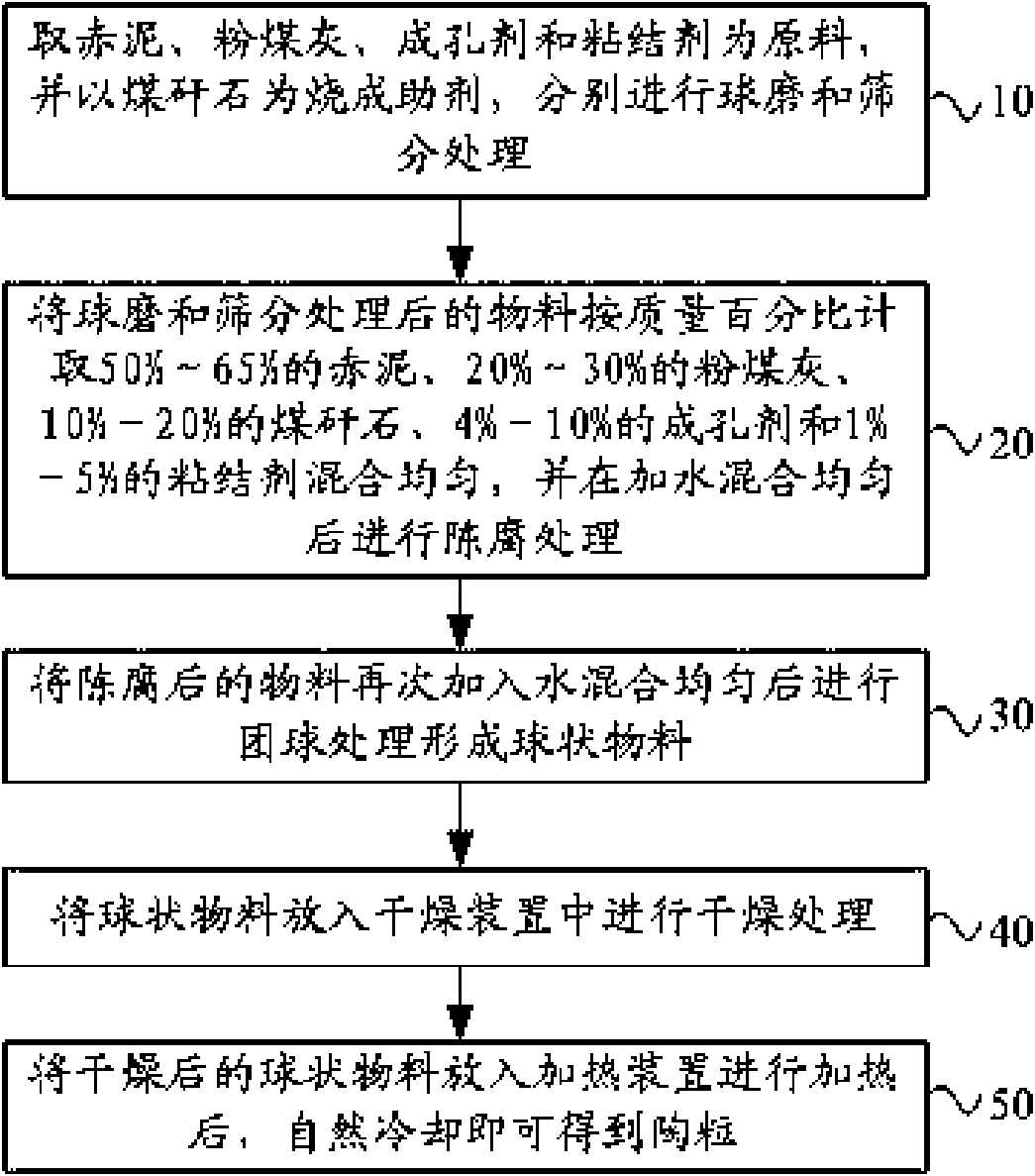

[0025] figure 1 It is a schematic flow diagram of the preparation method of ceramsite of the present invention. Such as figure 1 As shown, the method includes the following steps:

[0026] Step 10. Take red mud, fly ash, pore-forming agent and binder as raw materials, and use coal gangue as sintering aid to perform ball milling and sieving respectively.

[0027] The chemical composition of the red mud of the present invention includes 23% to 26% SiO in weight percentage 2 , 4%~12% Fe 2 O 3 , 13%~15% Al 2 O 3 , 2%~4%Na 2 O and 42% to 57% CaO.

[0028] The chemical composition of the fly ash of the present invention includes 35%-45% SiO in weight percentage 2 , 3%~6% Fe 2 O 3 , 30%~40% Al 2 O 3 , 0.8%~1.2%Na 2 O and 6%-11% CaO.

[0029] The chemical composition of the coal gangue of the present invention includes 50% to 70% SiO in weight percentage 2 , 8%~11% Fe 2 O 3 , 18%~24% Al 2 O 3 , 0.1%~0.3%Na 2 O and 0.7% to 1.2% of CaO.

[0030] Among them, the red mud and fly ash are the main...

Embodiment 1

[0047] First, the red mud, fly ash, coal gangue, limestone and clay are respectively subjected to ball milling and sieving treatment; secondly, the material after ball milling and sieving is taken as 50% red mud and 30% powder according to its mass percentage. Coal ash, 10% coal gangue, 2% limestone and 8% clay are mixed uniformly, and 15% of the total mass of the mixed material is added to the mixture, and then the aging treatment is carried out for 8 hours; then, the stale Add 15% water to the total mass of the material again and mix it uniformly to form a spherical material; then put the spherical material into a drying device and dry it at 105°C for 11 hours; finally, put the dried spherical material into After the heating device is heated at 1140°C, the ceramsite can be obtained by natural cooling.

[0048] The ceramsite prepared by this example has an apparent porosity of 47.89%, a water absorption rate of 33.32%, and a bulk density of 1.53kg / m 3 , The crushing strength is ...

Embodiment 2

[0050] First, the red mud, fly ash, coal gangue, limestone and clay are respectively subjected to ball milling and sieving treatment; secondly, the material after ball milling and sieving treatment is taken as 60% red mud and 20% powder according to its mass percentage. Coal ash, 10% coal gangue, 6% limestone and 4% clay are mixed uniformly, and 20% of the total mass of the mixed material is added to the mixture, and then the aging treatment is carried out for 8 hours; then, the stale Add 10% water to the total mass of the material again and mix it uniformly to form a spherical material; then put the spherical material into a drying device and dry at 105°C for 9.5 hours; finally, put the dried spherical material into After the heating device is heated at 1160°C, the ceramsite can be obtained by natural cooling.

[0051] The ceramsite prepared by this embodiment has a apparent porosity of 48.83%, a water absorption rate of 32.19%, a bulk density of 1.52kg / m3, a crushing strength o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| crushing strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com