Method for constructing insulating layer of wall body by utilizing insulating mortar

A technology of thermal insulation mortar and thermal insulation layer, applied in thermal insulation, building components, building structure and other directions, can solve problems such as affecting thermal insulation effect and different compactness, and achieve the effect of saving material consumption, more pores, and saving construction and labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] 1. Composition of self-foaming thermal insulation mortar

[0026] According to the mass ratio, take 3-5 parts of expanded perlite, 5-10 parts of volcanic tuff, 10-15 parts of aluminate early strength cement, 1-5 parts of polyvinyl formal, saponin and sisal short fiber mixture 3 -6 parts and 1-5 parts of silicone water repellent.

[0027] Because the raw materials used have the properties of perlite inorganic foam aging resistance, volcanic tuff reinforcement, aluminate cement early strength, polyvinyl formal viscosity, saponin self-foaming, sisal fiber toughening and silicone water repellency.

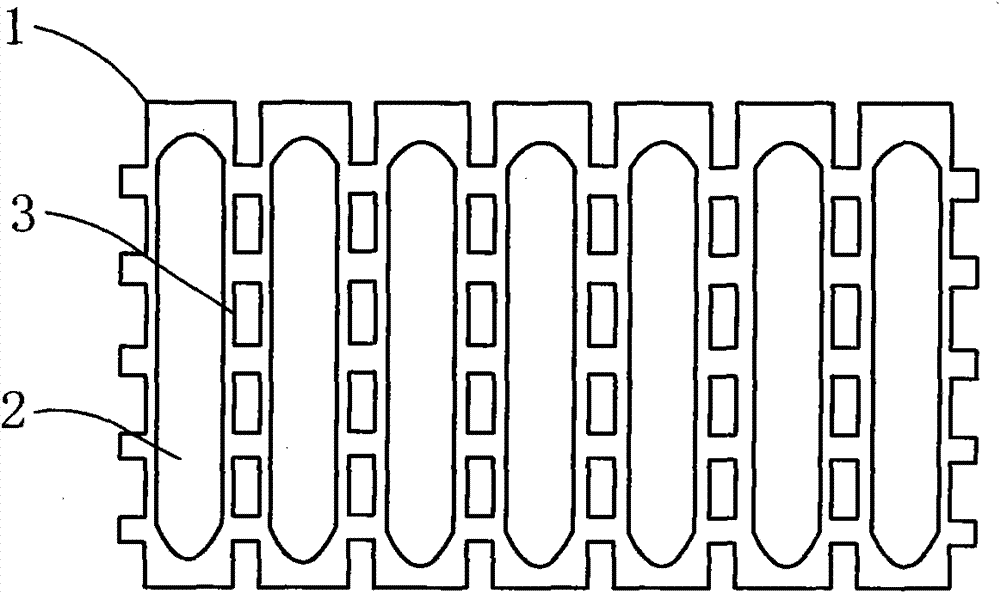

[0028] 1.1. Preparation of core tube sheet: A core tube sheet with multiple tubes arranged in parallel is made of paper or plastic. according to figure 1 As shown, closed core tubes 2 are provided at parallel intervals on the core tube sheet 1, and through holes 3 are distributed at intervals on the sheet between the core tubes and the core tubes.

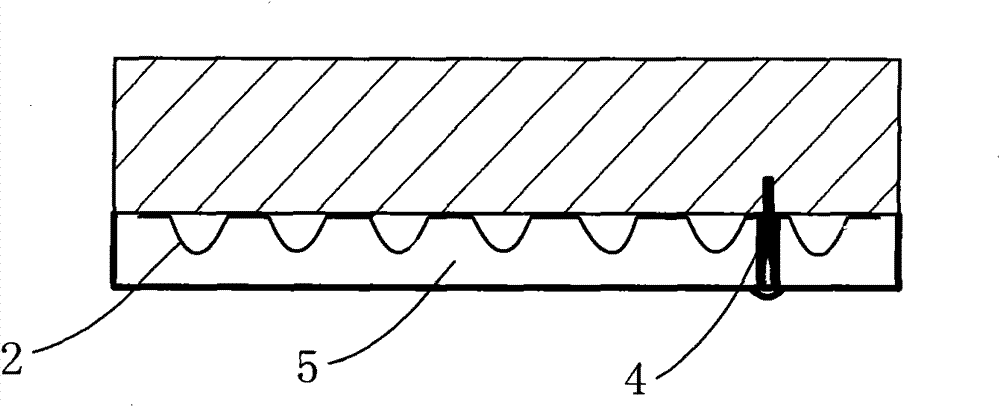

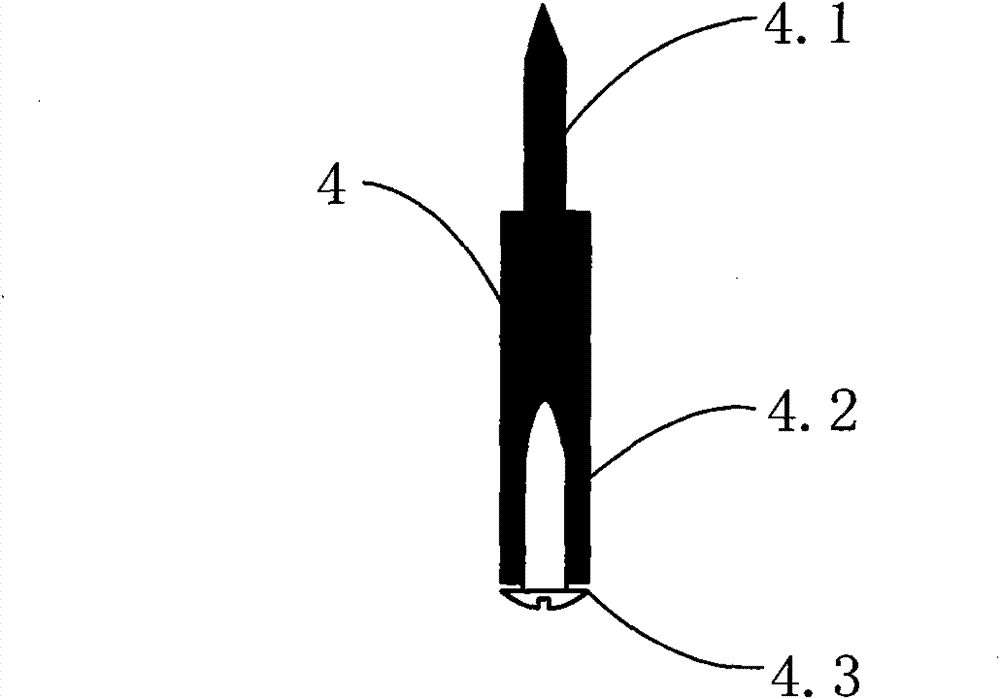

[0029] 1.2. Anchor nail pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com