Method for detecting content of elements in alloy raw material

A technology of element content and alloy, which is applied in the field of detection of element content in alloy raw materials, can solve problems such as excessive pores, incomplete removal of gas, and influence on the accuracy of element content detection results, so as to avoid excessive pores, reduce pores, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

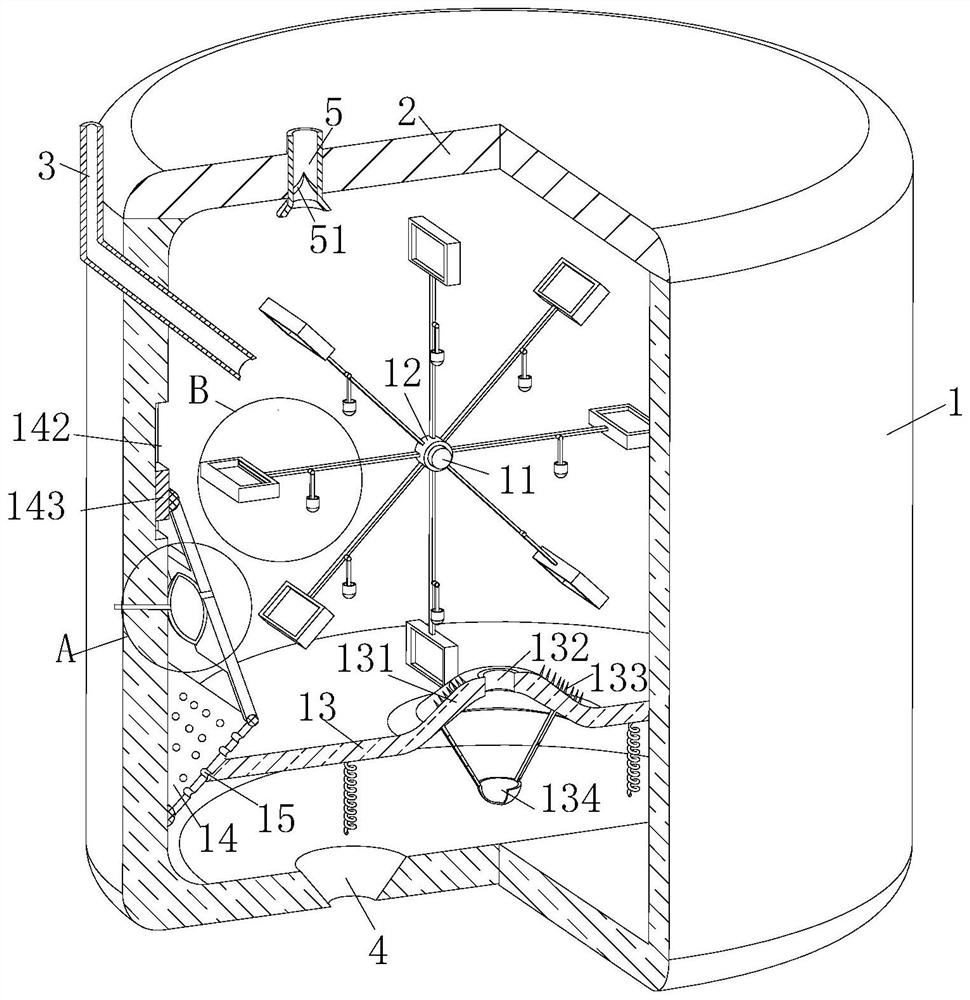

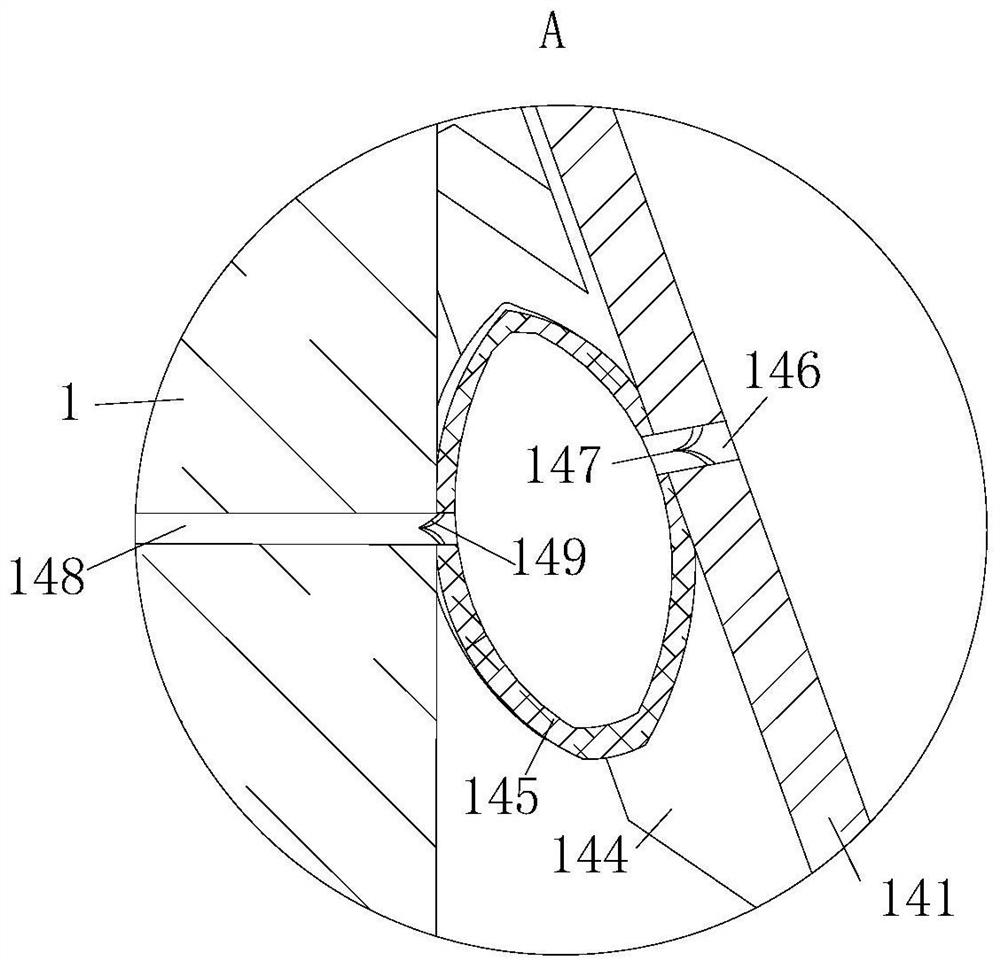

[0038] As a specific embodiment of the present invention, the end of the second pressing plate 14 away from the bottom of the can body 1 is provided with a No. 1 rod 141, and the No. 1 rod 141 is rotatably connected to the No. 2 pressing plate 14; A groove 142 is arranged on the inner surface of the side wall close to the tank cover 2, and a No. and the middle part of the No. 1 rod 141 is provided with a No. 3 pressure plate 144, and the surface of the No. 3 pressure plate 144 near the side wall of the tank body 1 is provided with an air bag 145, and the surface of the air bag 145 is provided with a part near the bottom of the tank body 1. There is an air inlet 146, and the air inlet 146 is provided with a No. 1 barrier piece 147, and the part of the surface of the air bag 145 close to the side wall of the tank body 1 is provided with an air outlet pipe 148, and the air outlet pipe 148 is far away from the side of the air bag 145. The end passes through the side wall of the ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com