Technological method of comprehensive utilization of separation and pyrolysis treatment of garbage

A process method and technology of a garbage disposal system, which are applied in the comprehensive utilization process field of garbage sorting and pyrolysis treatment, can solve the problems of low recovery efficiency, high operation cost, large amount of secondary landfill, etc., and reduce the cost of garbage disposal. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

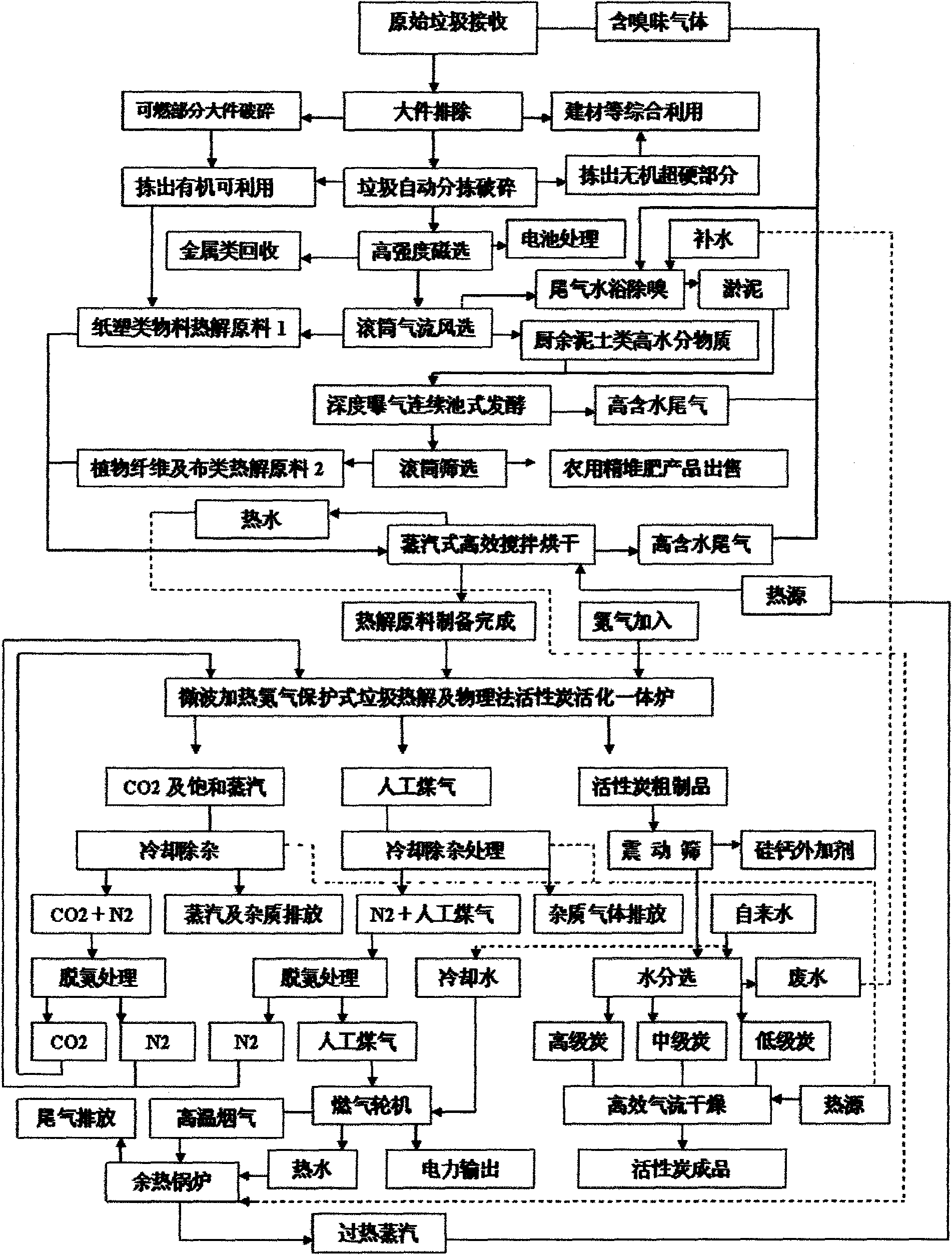

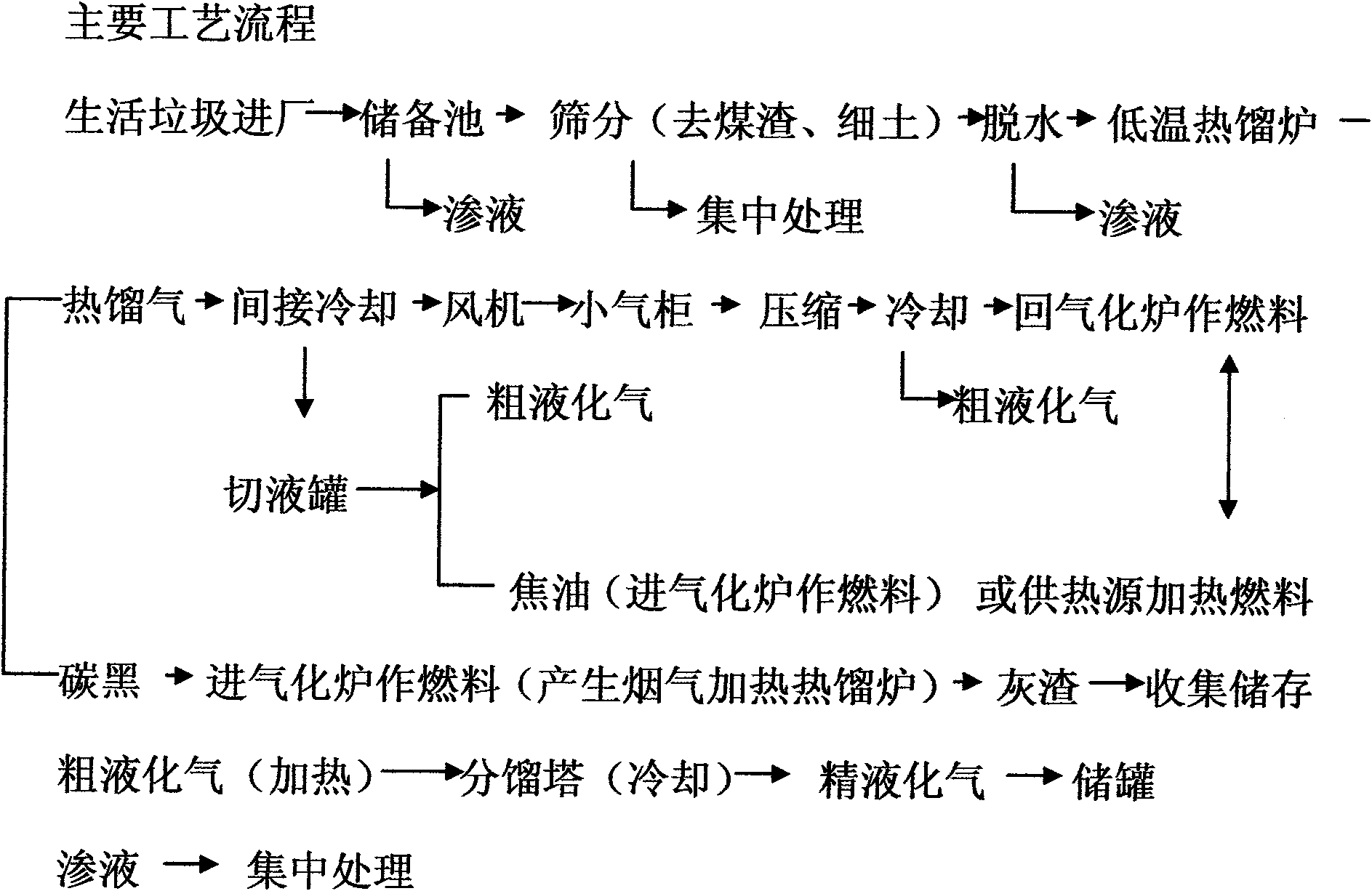

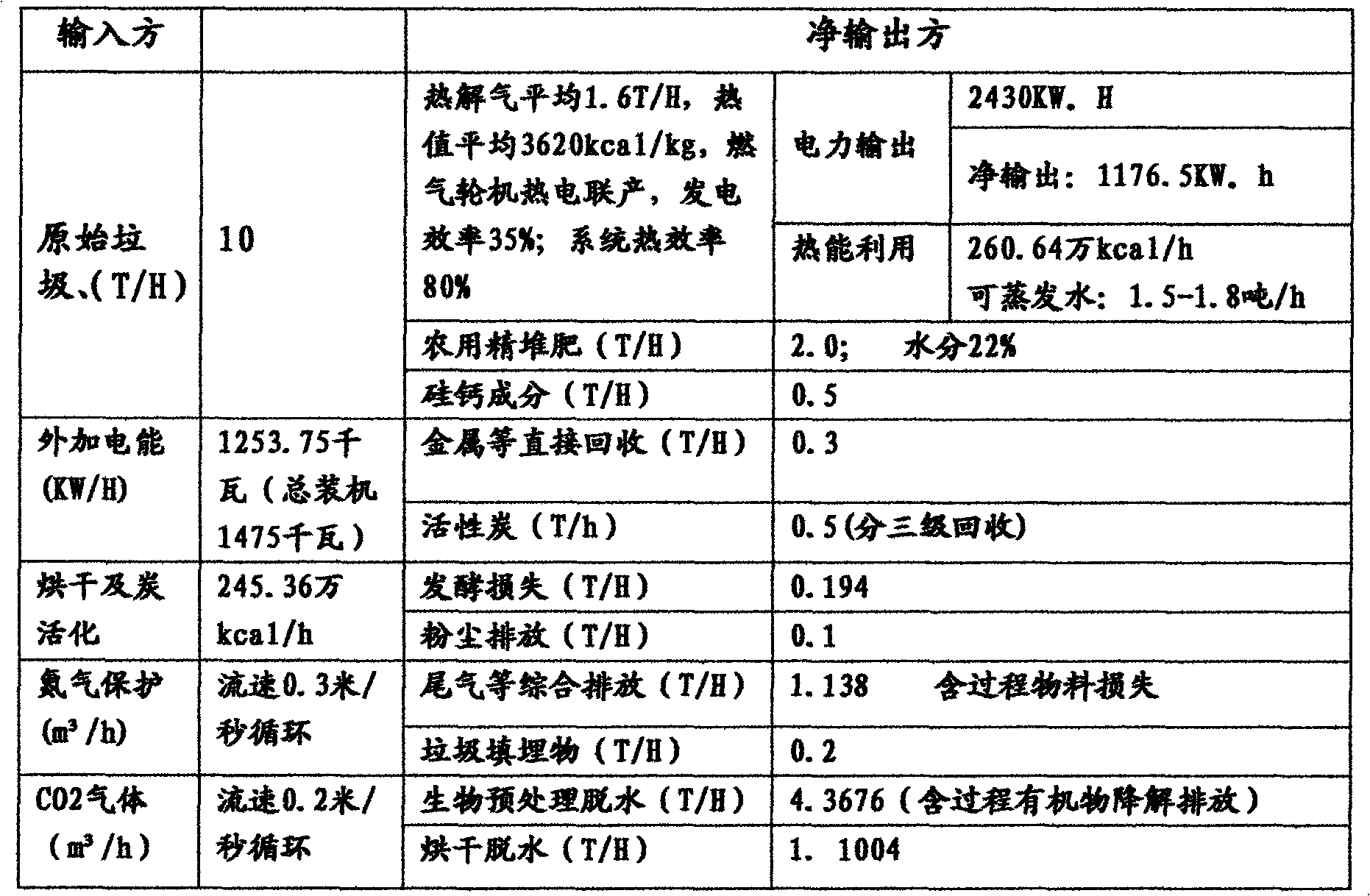

[0059] A comprehensive utilization process method for pyrolysis treatment of garbage sorting materials. The process method is composed of garbage primary sorting pulverizers, drum airflow sorting equipment, fermentation tanks, screening equipment, chopping equipment, drying equipment, and nitrogen protection microwave heating. It is realized in the municipal solid waste sorting and pyrolysis treatment system composed of low-temperature garbage sorting pyrolysis and carbon activation integrated furnace, gas turbine and waste heat boiler. The process method is realized by the following steps:

[0060] A. Garbage sorting and pretreatment:

[0061] A-1.Use the mixed garbage primary sorting and pulverizer in the garbage treatment system to sort and crush the municipal solid waste, extract the hard substances such as batteries, metals, and inorganic substances, and cooperate with the secondary separation of the drum airflow sorting device. Classification, the usable components in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com