Active-passive combined reactor core residual heat removal system for nuclear power station

A residual heat and passive technology, applied in nuclear power generation, reactors, nuclear engineering, etc., can solve problems such as unfavorable natural circulation heat exchange loops, reduce the risk of radioactive leakage, strengthen heat exchange capacity, and improve inherent safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

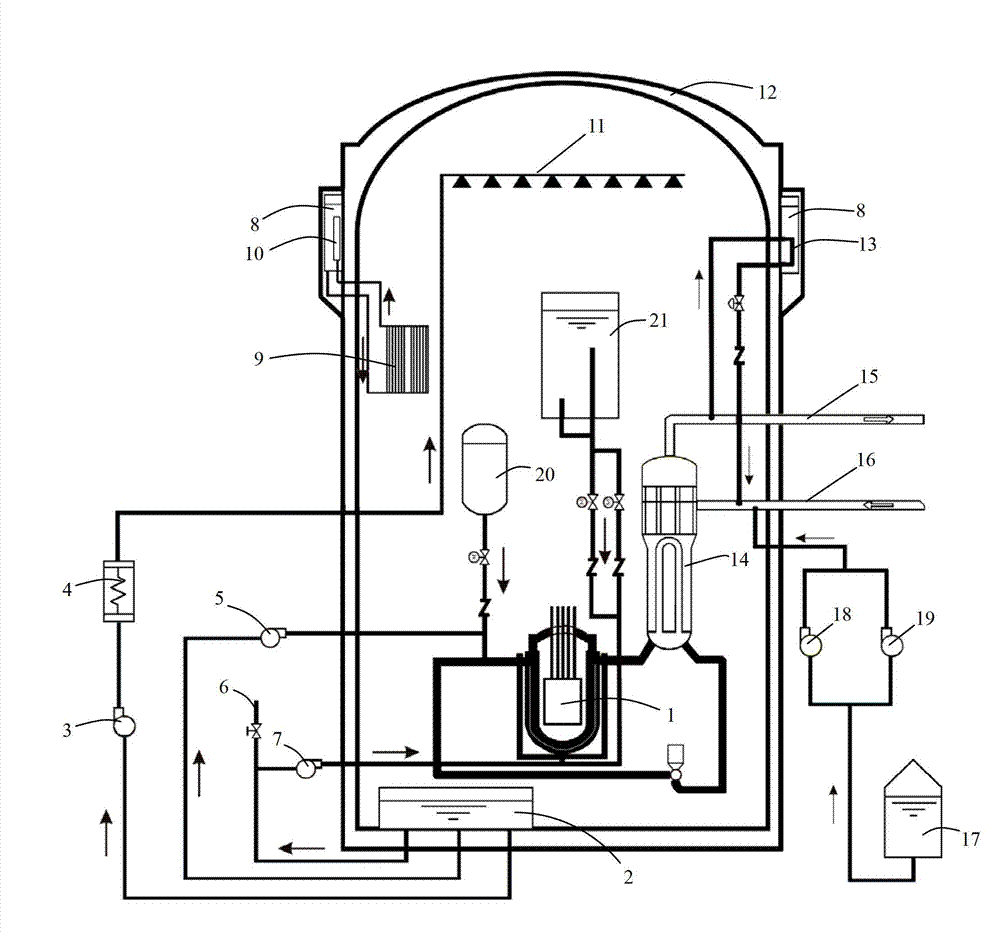

[0037] Such as figure 1 As shown, a complete nuclear power plant combined active and passive core residual heat removal system, including safety injection system, containment spray system, auxiliary water supply system, reactor cavity water injection system, secondary side passive residual heat removal system, non-active Active containment heat export system. Wherein, the safety injection system includes a refueling water tank 2 arranged in the pit below the core 1 inside the containment, and the bottom of the refueling water tank 2 is connected to the cold section of the reactor primary circuit through the pipeline through the safety injection pump 5 At the same time, a pipeline can also be connected with the hot section of the primary circuit of the reactor after passing through the safety injection pump (not shown in the figure); a passive safety injection box 20 is arranged above the reactor, and the safety injection box 20 It is connected to the cold section of the prima...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com