Integrated heat exchanger for use in a refrigeration system

a heat exchanger and refrigeration system technology, applied in the field of refrigeration systems, can solve the problems of affecting fuel economy, limiting the ability of the vehicle's design to achieve aerodynamic slipperiness, and many such systems are prone to refrigerant leakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

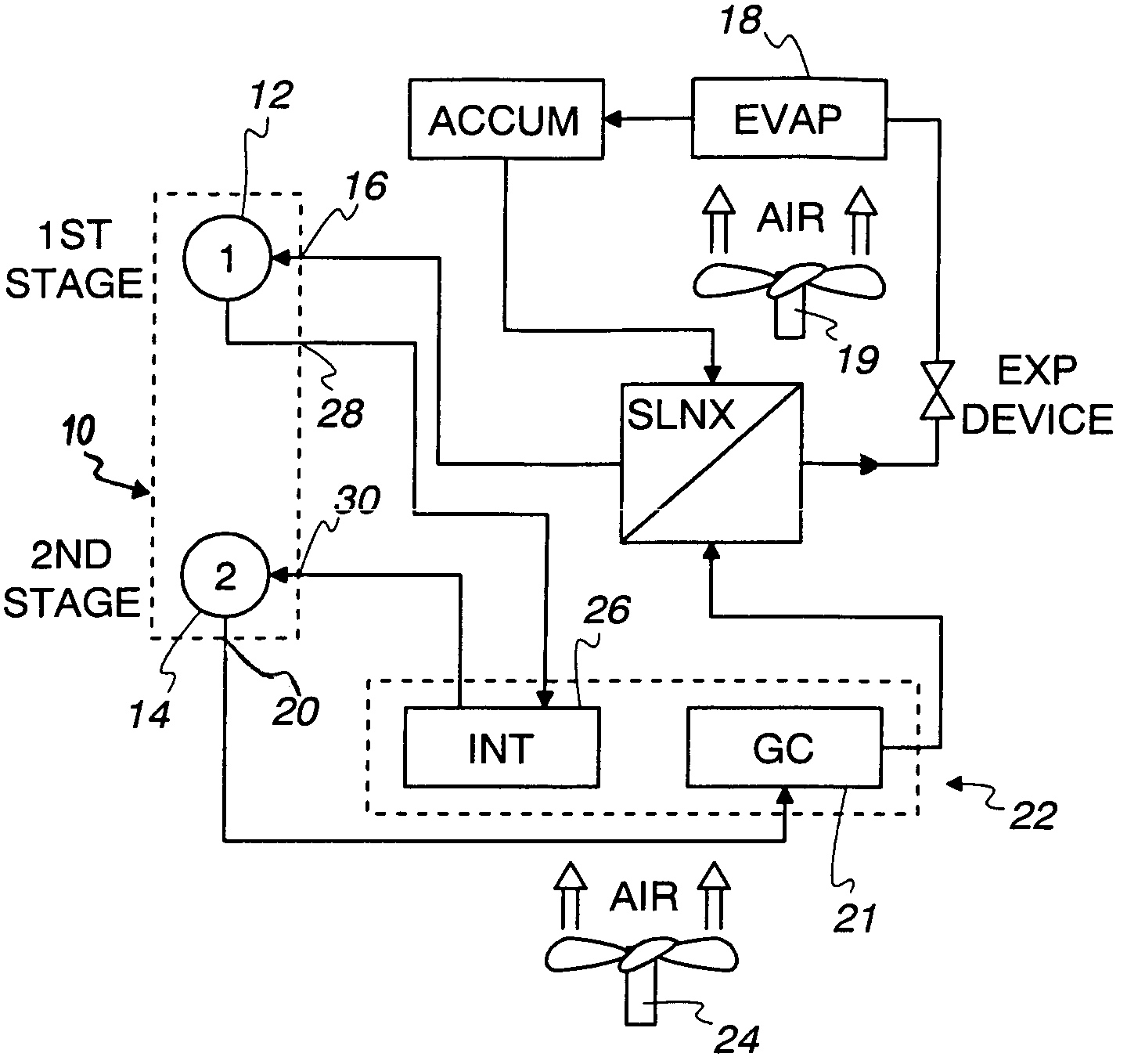

[0032] Before proceeding to the detailed description of the various embodiments, it is to be understood that the term “refrigeration system” as used herein is used in a broad sense to include any vapor compression based system utilized for cooling other objects. It is intended to include not only refrigeration systems in the narrow sense, such as refrigerators, refrigerated vehicles, etc. but also to include systems utilized for cooling spaces and / or occupants of such spaces, more narrowly understood to refer to air conditioning systems.

[0033] It is also to be noted that the invention is applicable to systems employed with refrigerants that in fact substantially fully change from the vapor phase to the liquid phase in a heat exchanger typically termed a condenser as well as in the systems utilizing so called transcritical refrigerants, such as carbon dioxide, wherein true condensation does not fully occur but nonetheless require a gas cooler for cooling the refrigerant after it has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com