Compact HVAC system for a motor vehicle

a hvac system and motor vehicle technology, applied in the direction of cooling fluid circulation, domestic cooling apparatus, lighting and heating apparatus, etc., can solve the problems of high-volume components of air conditioning as known from stationary air conditioning units that cannot be used, assembly is expensive, and potential leakage points that could only be corrected with very much time and cost consumed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0088]The following detailed description and appended drawings describe and illustrate various embodiments of the invention. The description and drawings serve to enable one skilled in the art to make and use the invention, and are not intended to limit the scope of the invention in any manner. In respect of the methods disclosed, the steps presented are exemplary in nature, and thus, the order of the steps is not necessary or critical.

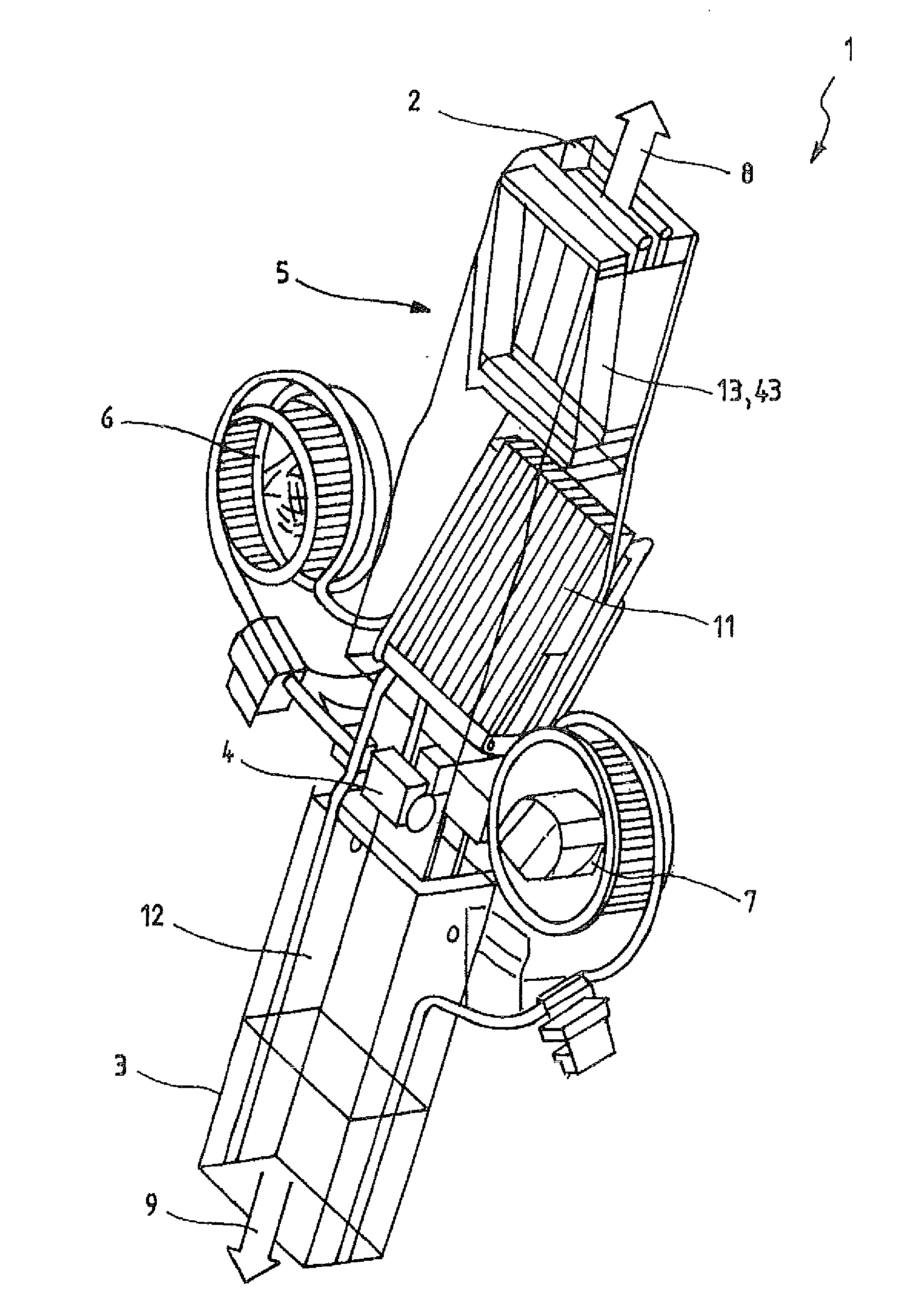

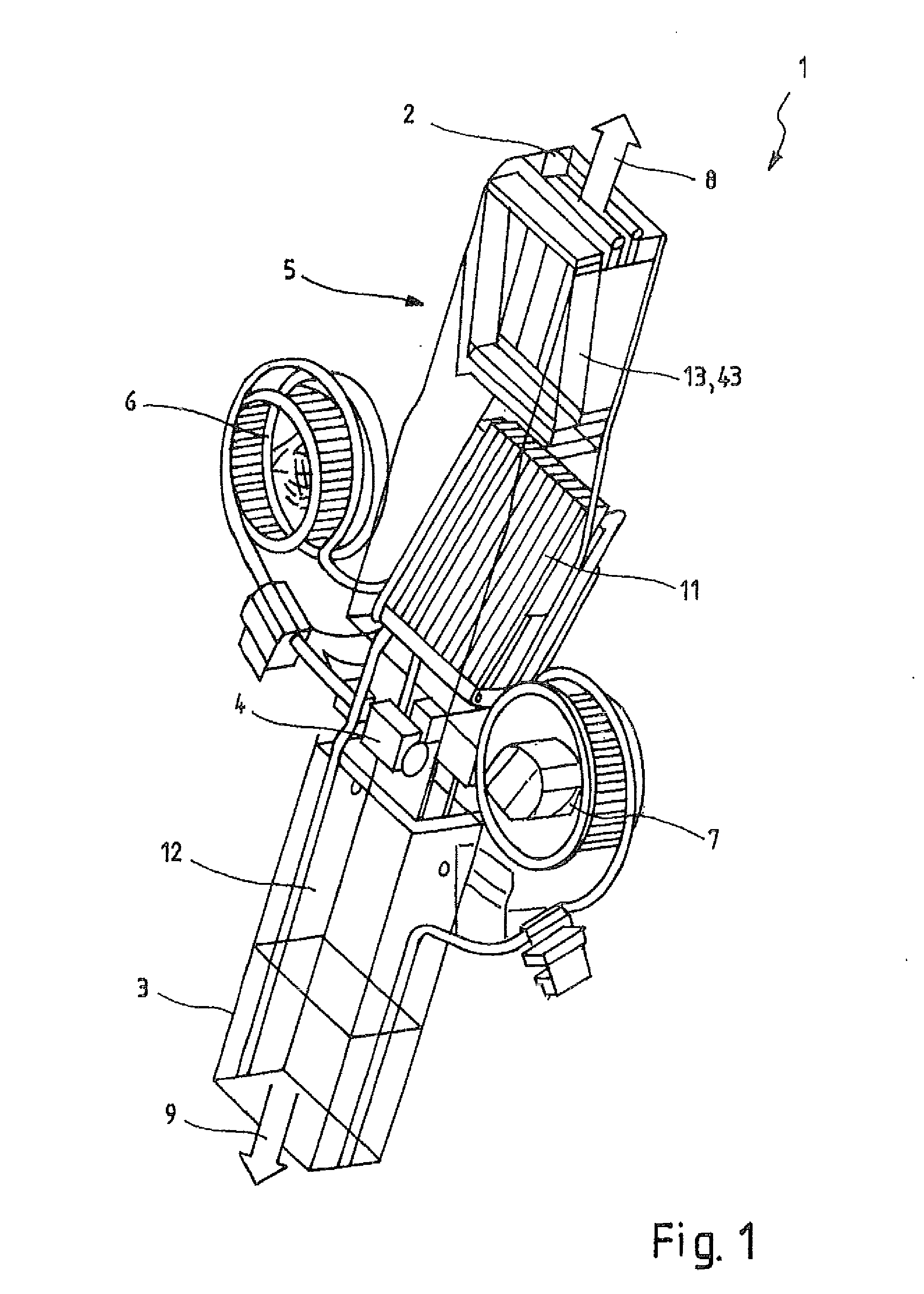

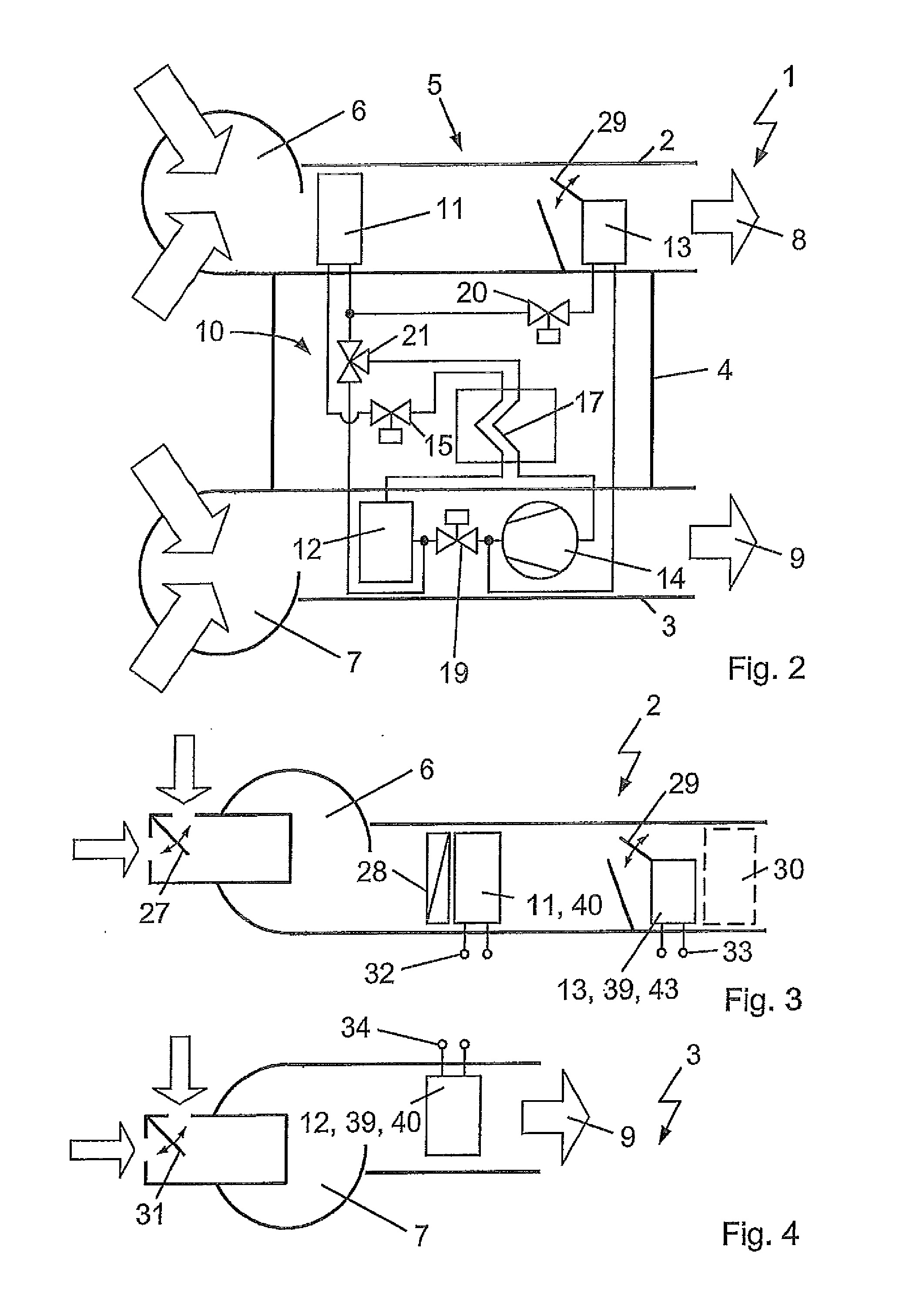

[0089]In FIG. 1, the compact vehicle HVAC system 1 according to the invention with a linear arrangement of the flow channels is shown. The casings of the evaporator unit 2 and the condenser unit 3, each forming a flow channel of a fresh / recirculated air system, have a rectangular flow cross-section in the range of the channels and are displaced with their faces to each other, linearly after each other. The faces displaced to each other are established closed, whereas the respective opposite sides, as sides of air exit, are established open. In an alte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com