Device and method of reclaim and processing tail gas of sulfur

A technology for tail gas treatment and sulfur recovery, which is applied in separation methods, chemical instruments and methods, sulfur preparation/purification, etc., can solve problems such as sulfur dioxide penetration, incomplete hydrogenation, and large economic losses, so as to simplify the process and reduce the Flow rate and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

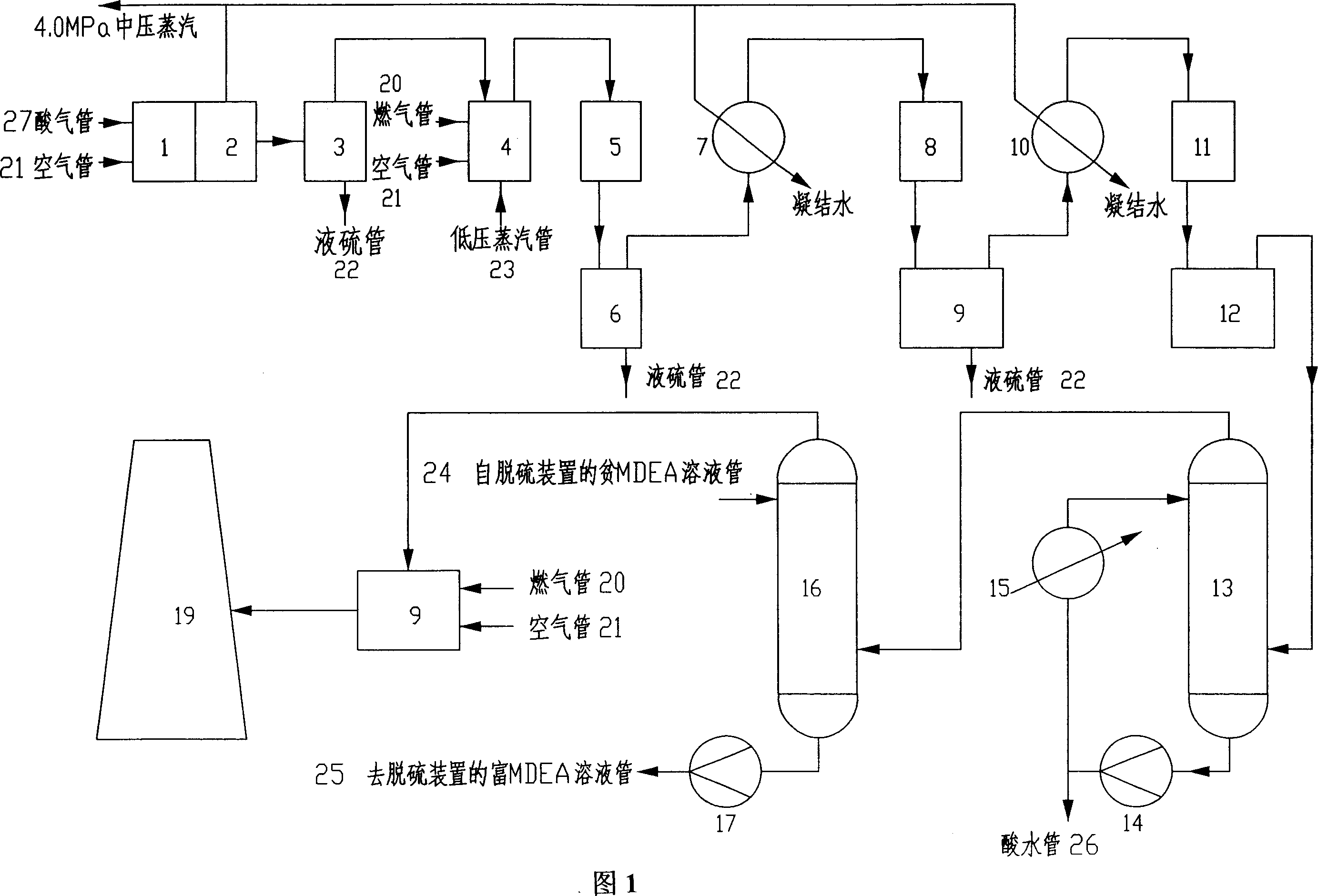

[0037]The sulfur recovery and tail gas treatment device for hydrogen production in the reheat furnace has a simple structure and is easy to manufacture. As shown in Figure 1, the device includes a thermal reaction section, a catalytic reaction section, and a reduction absorption section. The thermal reaction section includes the main combustion furnace 1, waste heat Boiler 2 and primary condensing cooler 3, one end of main combustion furnace 1 is connected to hydrogen sulfide gas pipe 27 and air pipe 21, the other end is connected to primary condensing cooler 3 through waste heat boiler 2, and the lower end of primary condensing cooler is connected to liquid The sulfur pipe 22 is connected, and the upper end of the first-stage condensing cooler is connected to the first-stage reheating hydrogen production furnace 4; the catalytic reaction section contains two-stage reheaters, two-stage reactors and two-stage condensing coolers, and the process gas is reheated by two stages Afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com