Split type profile material forming die

A molding die, split type technology, applied in the direction of metal extrusion dies, etc., can solve the problems of poor flatness, affecting the experimental effect of profile forming dies, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings.

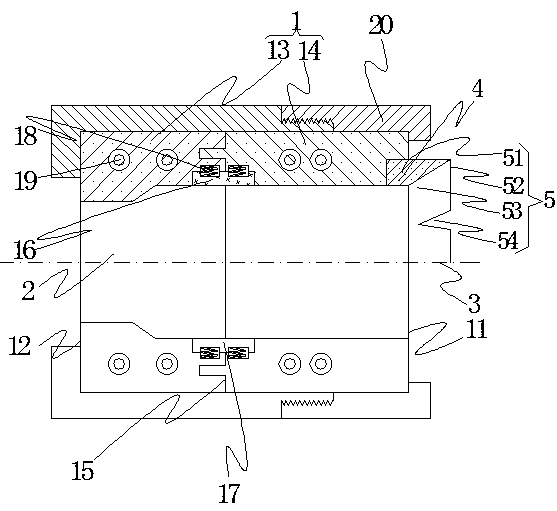

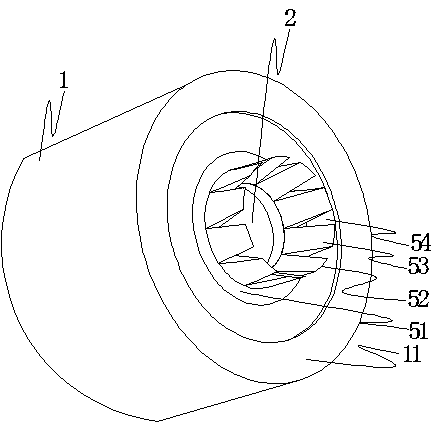

[0019] Such as figure 1 As shown, a split-type profile forming mold includes a mold body 1, the mold body has a molding cavity 2, the mold body has a rear side 11 where molding material enters, and the molding material enters from the molding cavity The front side 12 coming out of the center, the molding inner cavity is the cavity that penetrates from the back side to the front side, and the mold body also has a center connection line 3 connecting the center of the back side and the center of the front side; its characteristics are: The mold body is composed of two molds, the two mold monomers are the front monomer 13 and the rear monomer 14 respectively, and the connecting part of the front monomer and the rear monomer is the junction 15, Their junctions are matched and connected to form the mold body, and the junctions are longitudinally cut into the molding inner c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com