Feeding device for taking and placing materials through air pressure change

A technology of changing air pressure and picking and unloading materials, which is applied in the direction of transportation, packaging, and conveyor objects. It can solve the problems of difficult loading and unloading, positioning and clamping, scratches on the workpiece surface, and high cost, so as to reduce surface scratches and unloading. The effect of fast speed and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

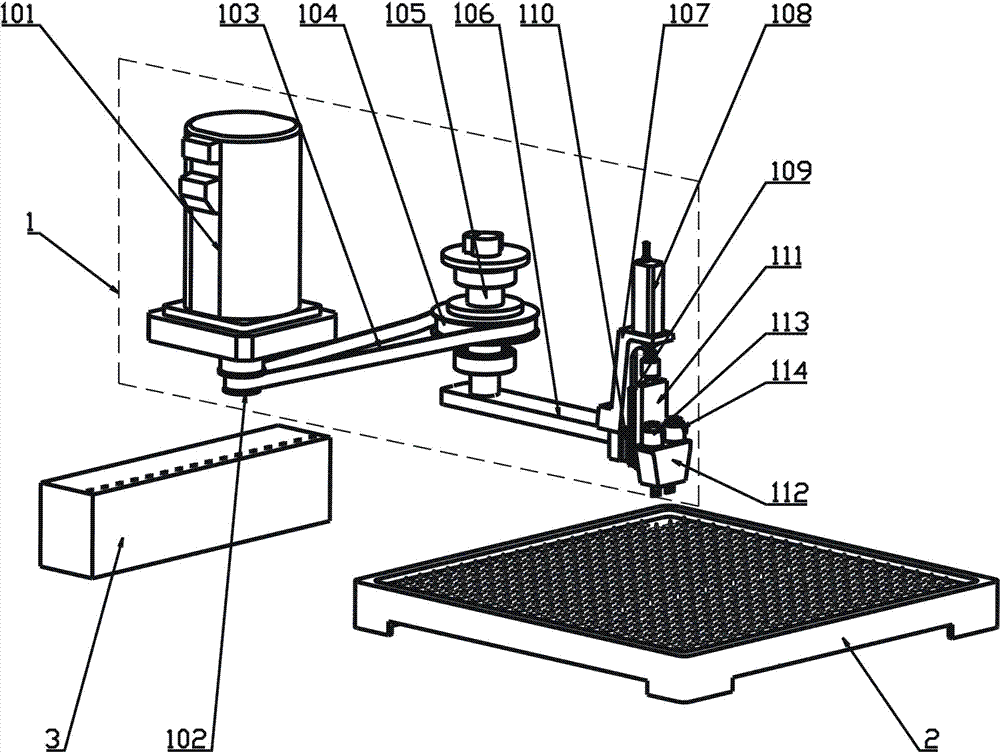

[0012] combine figure 1 with figure 2 As shown, a feeding device of the present invention for picking and discharging materials through changes in air pressure is composed of a feeding manipulator 1, a loading tray 2 and a positioning jig 3, and the loading tray 2 and the positioning jig 3 are respectively arranged on the upper The two sides of material manipulator 1.

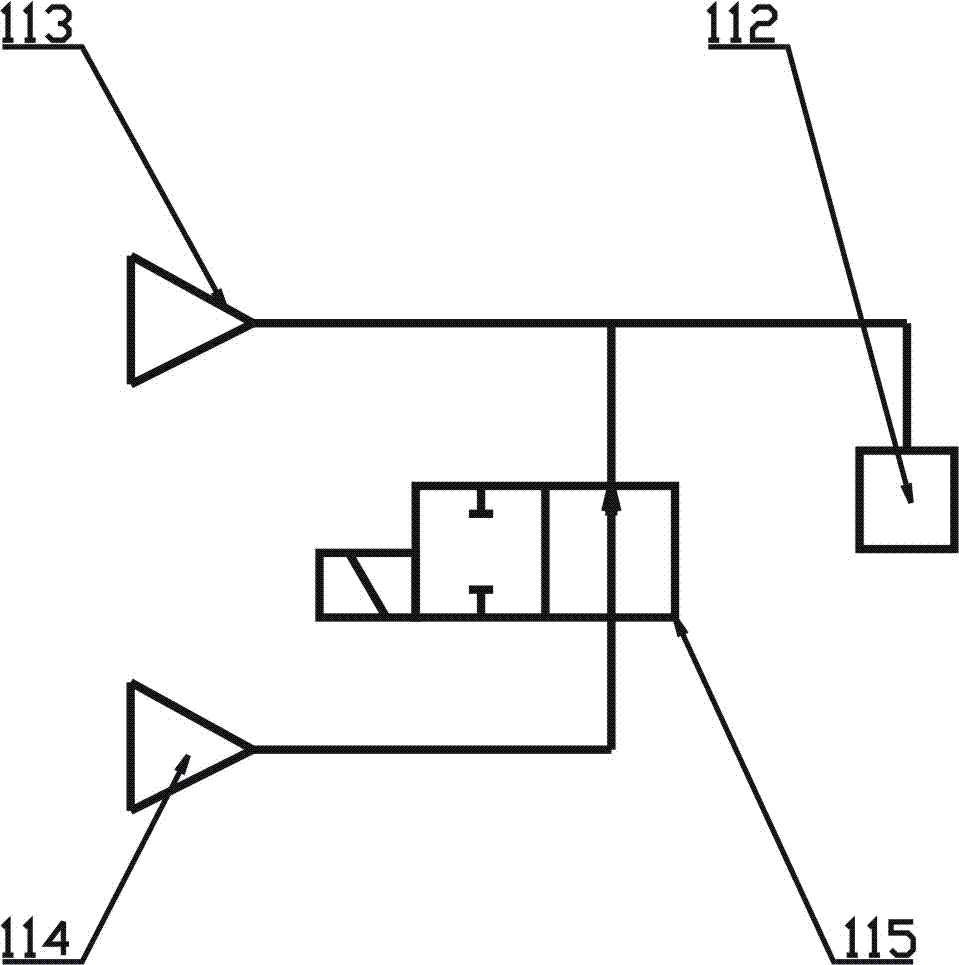

[0013] The feeding manipulator 1 comprises a servo motor 101, a small pulley 102, a synchronous belt 103, a large pulley 104, a rotating shaft 105, a swing arm 106, a mounting bracket 107, a cylinder 108, a guide rail 109, a slide block 110, a sliding base plate 111 and a vacuum Suction cup 112. Wherein the servo motor 101, the small pulley 102, the synchronous belt 103, the large pulley 104, the rotating shaft 105 and the swing arm 106 form the drive carrying part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com