Magnesium aluminum alloy spiral welded pipe production unit

A technology of spiral welded pipes and magnesium-aluminum alloys, applied in other manufacturing equipment/tools, manufacturing tools, etc., can solve the problems of low quality of alloy pipes, restricting economic development, complex processing technology, etc., achieving high production efficiency and reducing scratches , Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

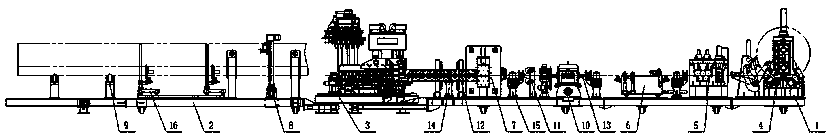

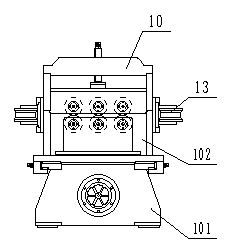

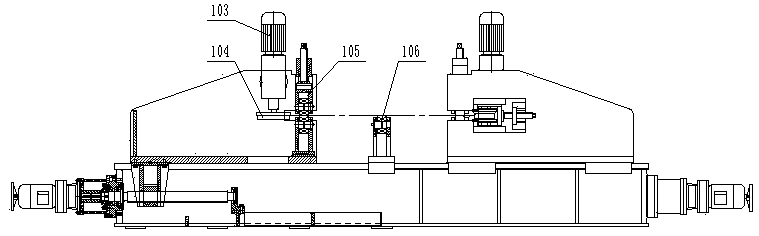

[0024] Such as figure 1 As shown, the magnesium-aluminum alloy spiral welded pipe production unit includes: a front axle 1, a rear axle 2 and a forming machine 3, one end of the front axle 1 is hinged to the bottom of the forming machine 3, and one end of the rear axle 2 is fixed to the forming machine 3 At the bottom of the bottom of the front axle 1, the direction from the end of the front axle 1 to the forming machine is arranged coaxially with an uncoiler 4 for shoveling aluminum coils, a pinch leveler 5 for aluminum strips and a pair of aluminum strips The cutting butt welding machine 6 connected by welding and the delivery machine 7 as the power source of the unit, the rear axle 2 is provided with an external welding device 8 and a plurality of support rollers 9 for supporting the welded pipe in the direction from the forming machine to the end , the aluminum strip welded by the cutting butt welding machine 6 enters the delivery machine 7 after passing through the edge m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com