Paints protection method before drawing and forming sheet metal parts

A technology of sheet metal parts and deep drawing, which is applied in the direction of coating, liquid coating device on the surface, surface pretreatment, etc., to achieve the effect of solving the adhesion of paint film and scratches of parts, convenient operation and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

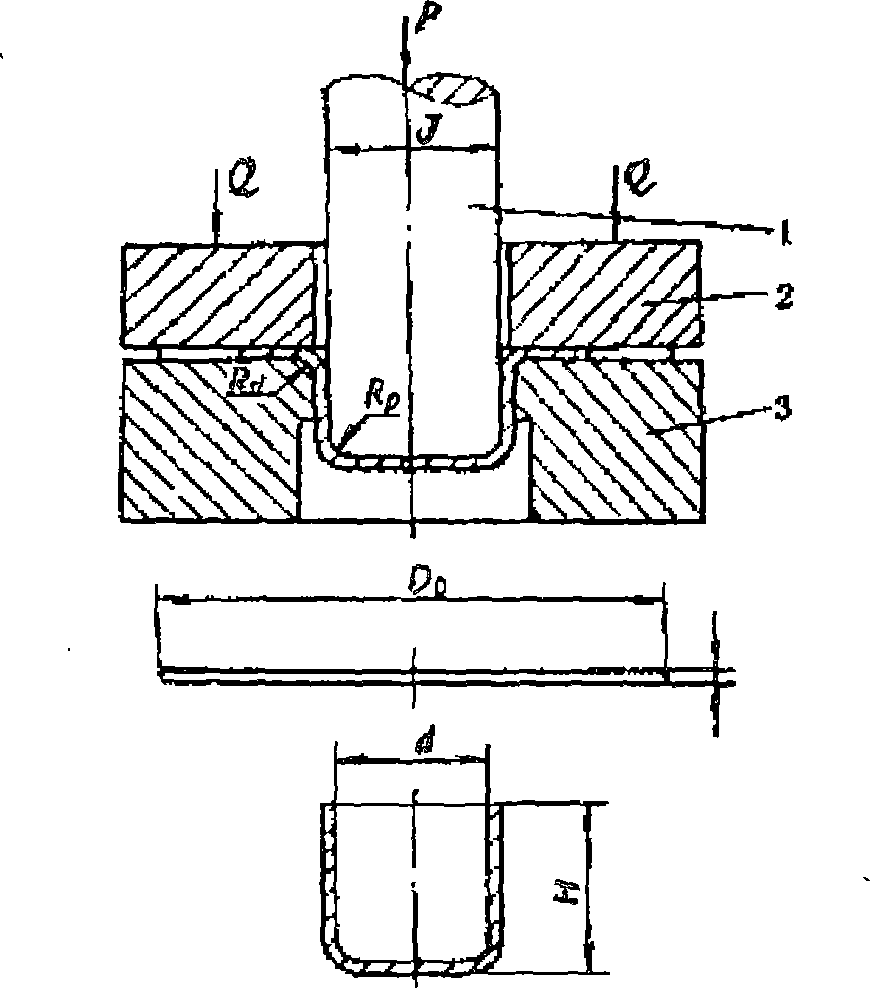

Method used

Image

Examples

Embodiment 1

[0034] Use organic solvents to degrease the sheet metal parts of the CFM56-7 engine fairing, and then dry the parts at room temperature.

[0035] Add the thinner to the paint (PROPACO R) and stir evenly. The amount of the thinner added is 15-17s after adding the thinner.

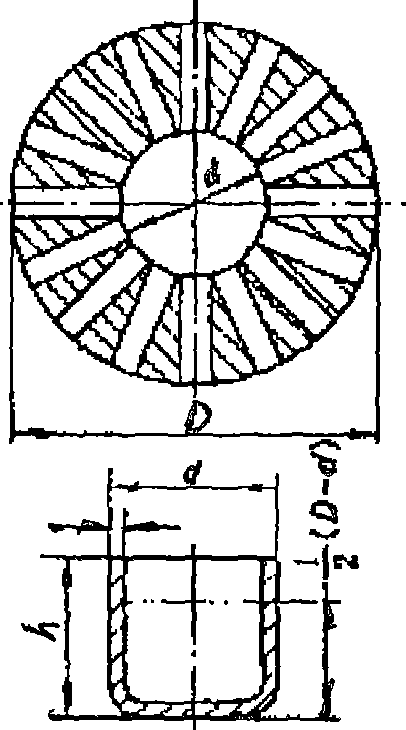

[0036] Use spraying equipment to evenly spray the diluted paint on the surface of the parts. When spraying, use clean and dry compressed air treated by an oil-water separator. The compressed air pressure is 0.2MPa, and the spraying angle is 45~90°. The spraying distance is 200mm~ 300mm; Dry the sprayed parts, and the drying conditions are natural drying at room temperature for 24 hours, and the thickness of the paint after curing is 15 microns.

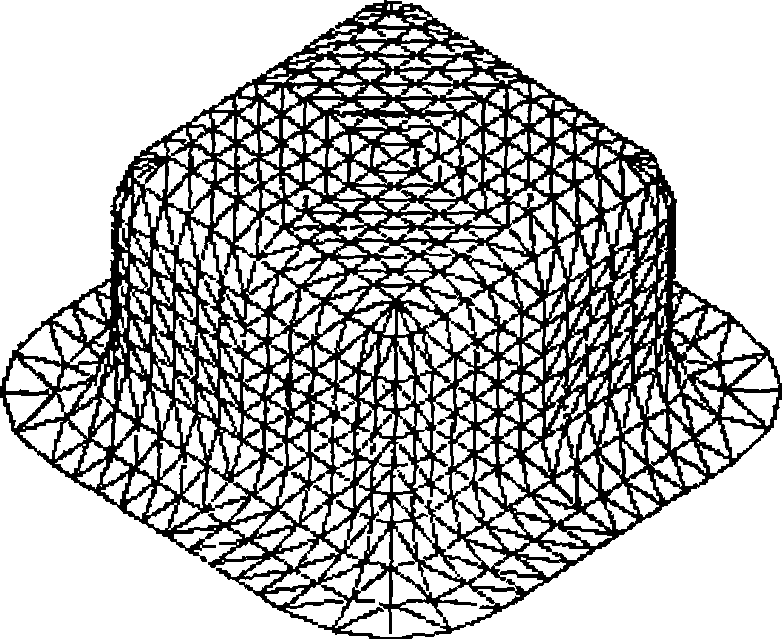

[0037] After spraying protection, the CFM56-7 engine fairing sheet metal parts are formed by stamping and deep drawing, and their appearance is like Figure 6 Shown. With the use of domestic paint protection technology to stamp the surface of the part after deep drawing...

Embodiment 2

[0039]Use organic solvents to degrease the sheet metal parts of the CFM56-7 engine fairing, and then dry the parts at room temperature.

[0040] Add the thinner to the paint (PROPACO R) and stir evenly. The amount of the thinner added is 15-17s after adding the thinner.

[0041] Use spraying equipment to evenly spray the diluted paint on the surface of the parts. When spraying, use clean and dry compressed air treated by an oil-water separator. The compressed air pressure is 0.4MPa, and the spraying angle is 45~90°. The spraying distance is 200mm~ 300mm; Dry the sprayed parts under the conditions of natural drying for 24 hours at room temperature, and the cured paint has a thickness of 13 microns.

[0042] After spraying protection, the CFM56-7 engine fairing sheet metal parts are formed by stamping and deep drawing, and their appearance is like Figure 7 Shown. With the use of domestic paint protection technology to stamp the surface of the part after deep drawing (such as Figure...

Embodiment 3

[0044] Use organic solvents to degrease the sheet metal parts of the CFM56-7 engine fairing, and then dry the parts at room temperature.

[0045] Add the thinner to the paint (PROPACO R) and stir evenly. The amount of the thinner added is 15-17s after adding the thinner.

[0046] Use spraying equipment to evenly spray the diluted paint on the surface of the parts. When spraying, use clean and dry compressed air treated by an oil-water separator. The compressed air pressure is 0.6MPa, and the spraying angle is 45~90°. The spraying distance is 200mm~ 300mm; Dry the sprayed parts under the conditions of natural drying for 24 hours at room temperature, and the thickness of the paint after curing is 10 microns.

[0047] After spraying protection, the CFM56-7 engine fairing sheet metal parts are formed by stamping and deep drawing, and their appearance is like Figure 8 Shown. Compared with the surface of the parts after stamping and deepening formed by using domestic paint protection te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com