Glass slide inserting machine

A technology for inserting slides and glass slides, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of glass slide scratches, material waste, scrapping, etc., so as to improve the efficiency of inserting slides and reduce the surface Scratches, waste reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

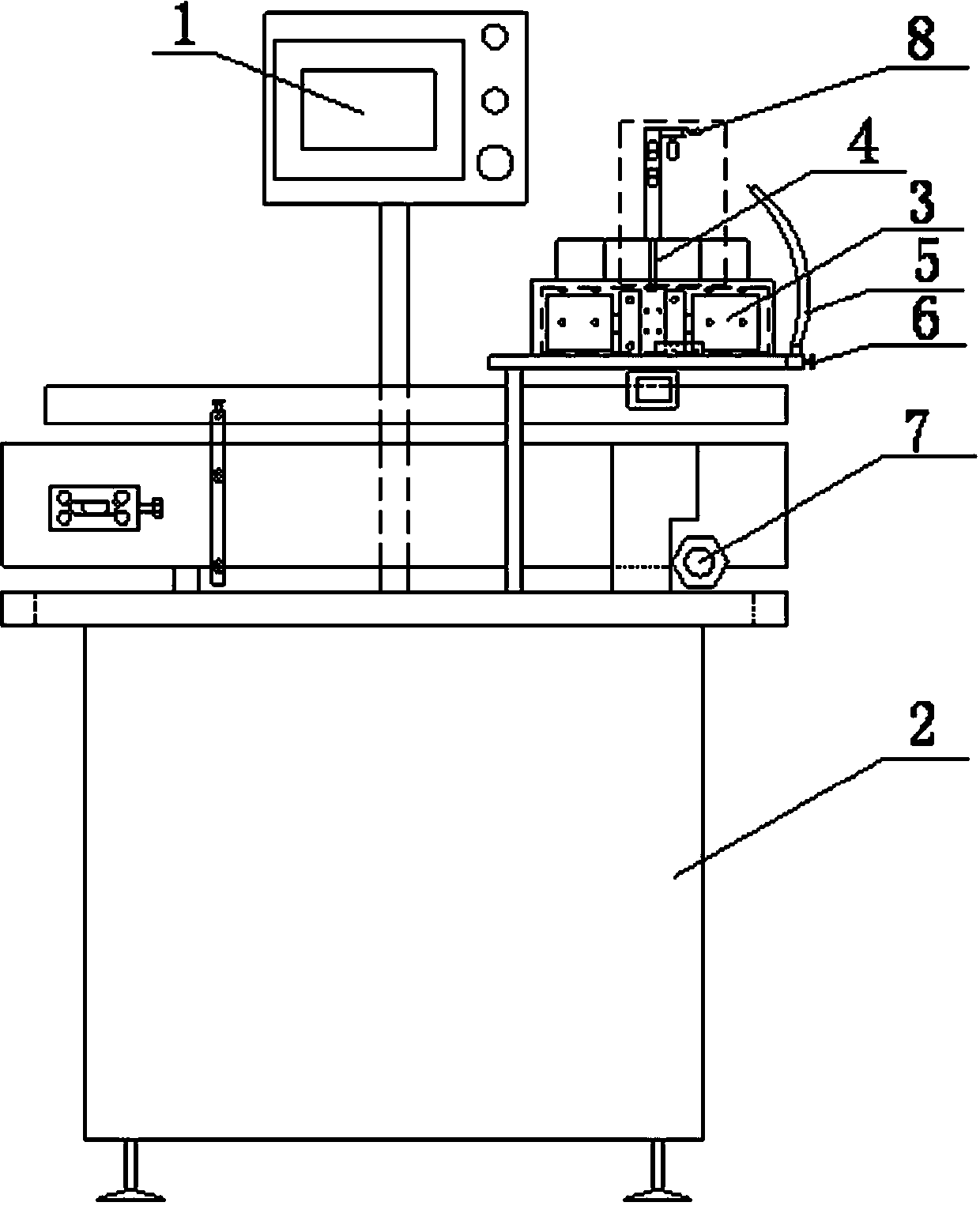

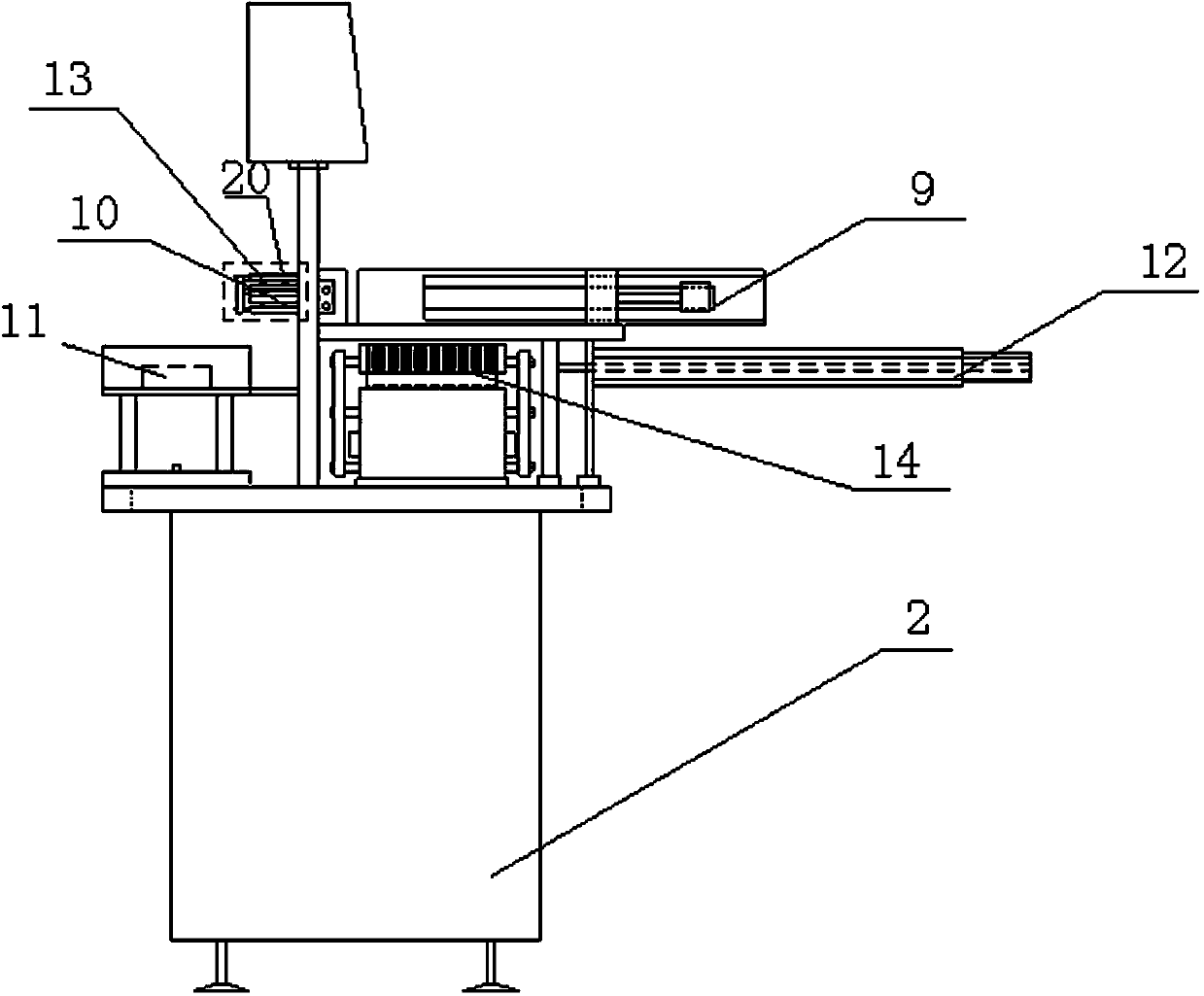

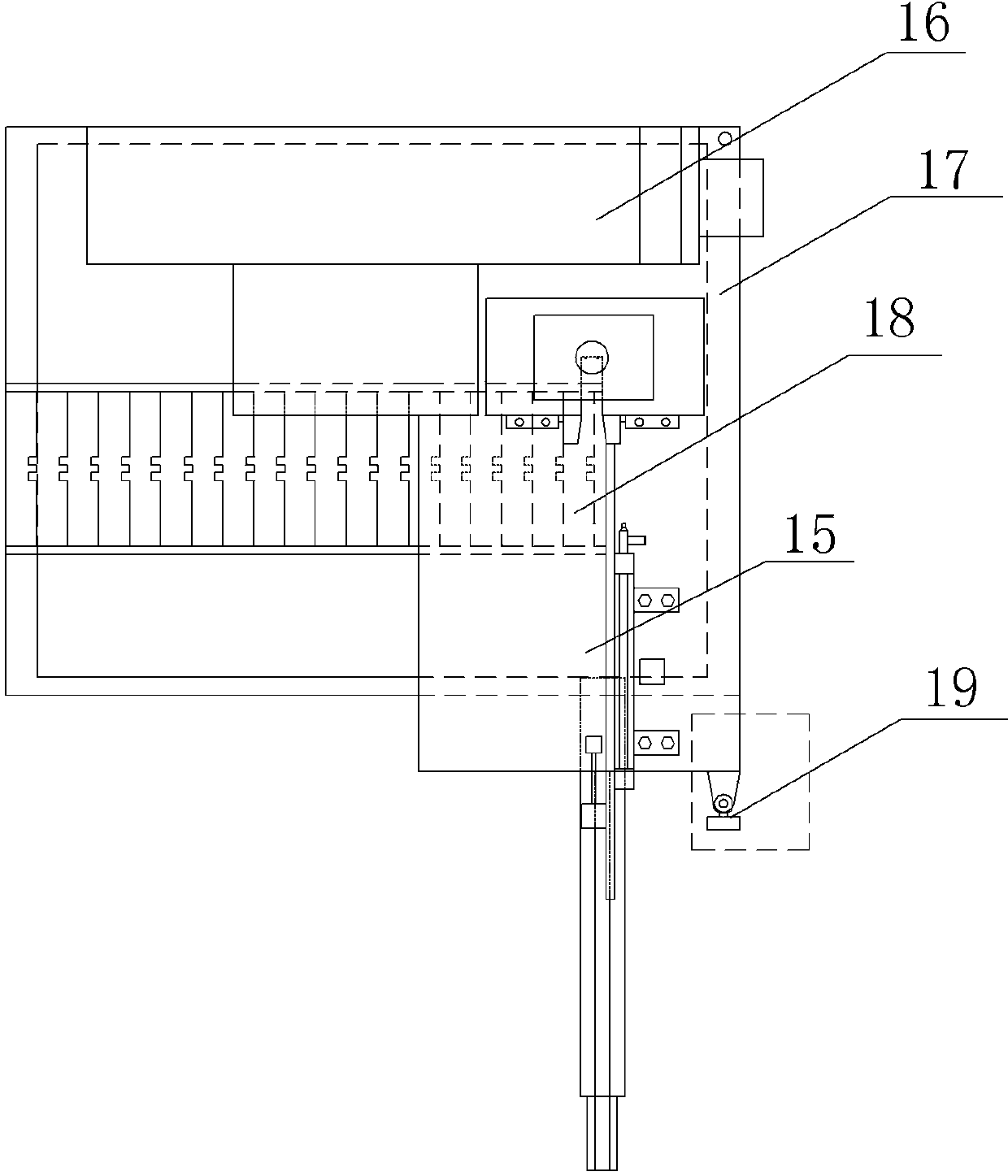

[0012] As shown in the figure, a slide insertion machine includes a display screen 1, a working table and an electrical cabinet 2, the electrical cabinet 2 is fixedly installed at the lower end of the working table, and the display screen 1 is installed at the upper end of the working table.

[0013] The working surface includes a conveyor belt 18, a working platform and a spraying device 5. A pressure gauge 19 is provided on one side of the working platform. The working platform includes a working platform I15 and a working platform II16. There is a copper rod 13 in the middle of cylinder I3, one side of pneumatic cylinder I3 is equipped with pneumatic cylinder II4, the other side of pneumatic cylinder I3 is equipped with spray device 5, and pneumatic cylinder I3 is connected with pneumatic cylinder III9 , the spray device 5 is provided with a water valve 6, the bottom of the spray device 5 is provided with a drainage tank 17, the copper rod 13 is connected with the pneumatic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com