Bio-based polysiloxane scratch-resistant auxiliary agent and preparation method thereof, and scratch-resistant composite material

A polysiloxane, bio-based technology, applied in the field of anti-scratch additives, can solve the problems of violating green development, non-renewable non-green resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0047] The present invention provides a preparation method of the bio-based polysiloxane anti-scratch additive described in the technical solution, comprising the following steps:

[0048] (1) mix hydrogenated cardanol, basic catalyst, organic solvent and halogenated olefin, and carry out substitution reaction to obtain intermediate;

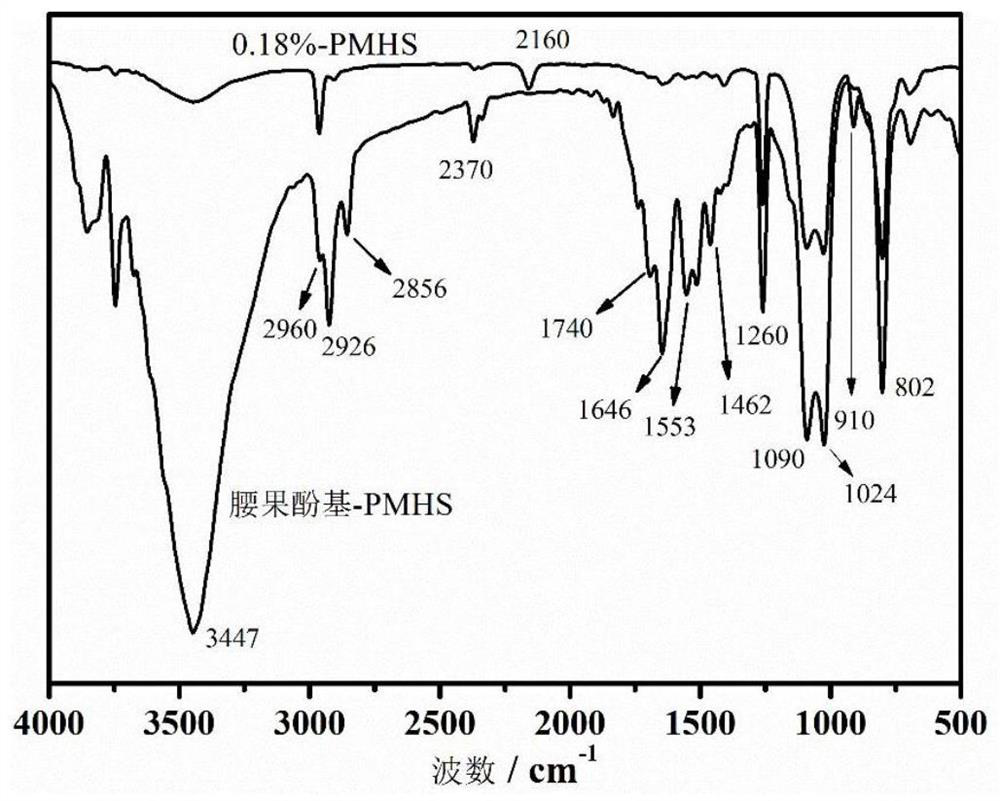

[0049] (2) Mix the intermediate obtained in the step (1) with the catalyst, toluene and low-hydrogen polysiloxane, and carry out a hydrosilylation reaction to obtain the bio-based polysiloxane of the formula (I) structure Scratch-resistant additives;

[0050] Alternatively, the unhydrogenated cardanol is mixed with the catalyst, toluene and low-hydrogen-containing polysiloxane for hydrosilylation reaction to obtain the bio-based polysiloxane anti-scratch additive with the structure of formula (II).

[0051] The invention mixes hydrogenated cardanol, a basic catalyst, an organic solvent and a halogenated olefin, and performs a substitution react...

Embodiment 1

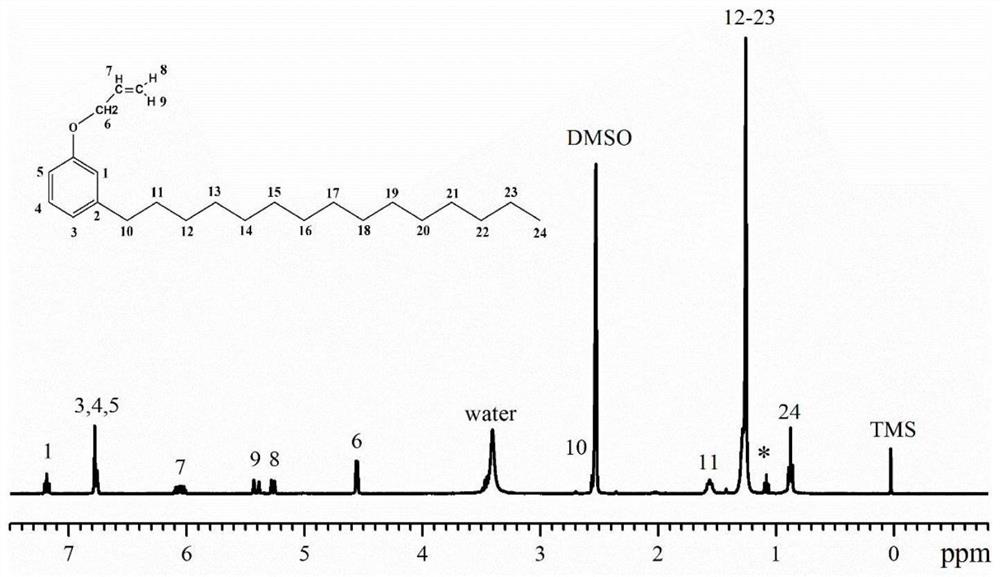

[0113] (1) Add the weighed cardanol derivative 3-pentadecylphenol (10mmol, 3.0451g) into 50mL of absolute ethanol solution, stir to dissolve it, and obtain the first reaction solution; / L KOH solution was added to the first reaction solution at a rate of 0.2-0.5mL / s; the bromopropene (10mmol, 0.86g) solution was gradually added dropwise to the first reaction solution at a rate of 0.06-0.12mL / s with a syringe solution to obtain a second reaction solution; heat the second reaction solution to reflux in an oil bath, set the temperature to 78° C., and react for 8 hours; use ethyl acetate to precipitate KBr generated in the reacted system, and filter to obtain the filtrate, set The temperature is 50°C for rotary steaming, the rotary steaming step is repeated twice to remove KBr; the wet method is passed through the column, and the eluent is prepared according to the ratio of petroleum ether: ethyl acetate = 10:1 ~ 20:1, and the column is purified The intermediate; the purified inte...

Embodiment 2

[0124] The difference from Example 1 is that the cardanol derivatives in step (1) are unhydrogenated cardanol; wherein, the unhydrogenated cardanol is a mixture, that is, four kinds of phenols composed of b=0,1,2,3 Composed of mixed phenols. The ratio of the amount of unhydrogenated cardanol, alkaline catalyst and propylene bromide is 1:1:1; the obtained intermediate is a mixed olefin composed of four cardanol groups, wherein the structural formula of the cardanol group mixed olefin is as follows Shown in formula (VII):

[0125]

[0126] b=0,1,2,3 in the formula (VII).

[0127] Step (2) The ratio of the amount of intermediate to chloroplatinic acid and low hydrogen-containing polysiloxane is 12:5.80×10 -7 :12. All the other operating steps are the same as in Example 1.

[0128] The structural formula of the bio-based-PMHS that step (2) obtains is shown in formula (VIII):

[0129]

[0130] Wherein, in formula (VIII), b=0,1,2,3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com