Tinsel wallpaper

A metal foil and metal foil layer technology, applied in the direction of metal coating, etc., can solve problems such as complex process, poor flatness, wallpaper scratches, etc., and achieve the effects of simplifying production methods, enhancing adhesion, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the embodiments and the accompanying drawings.

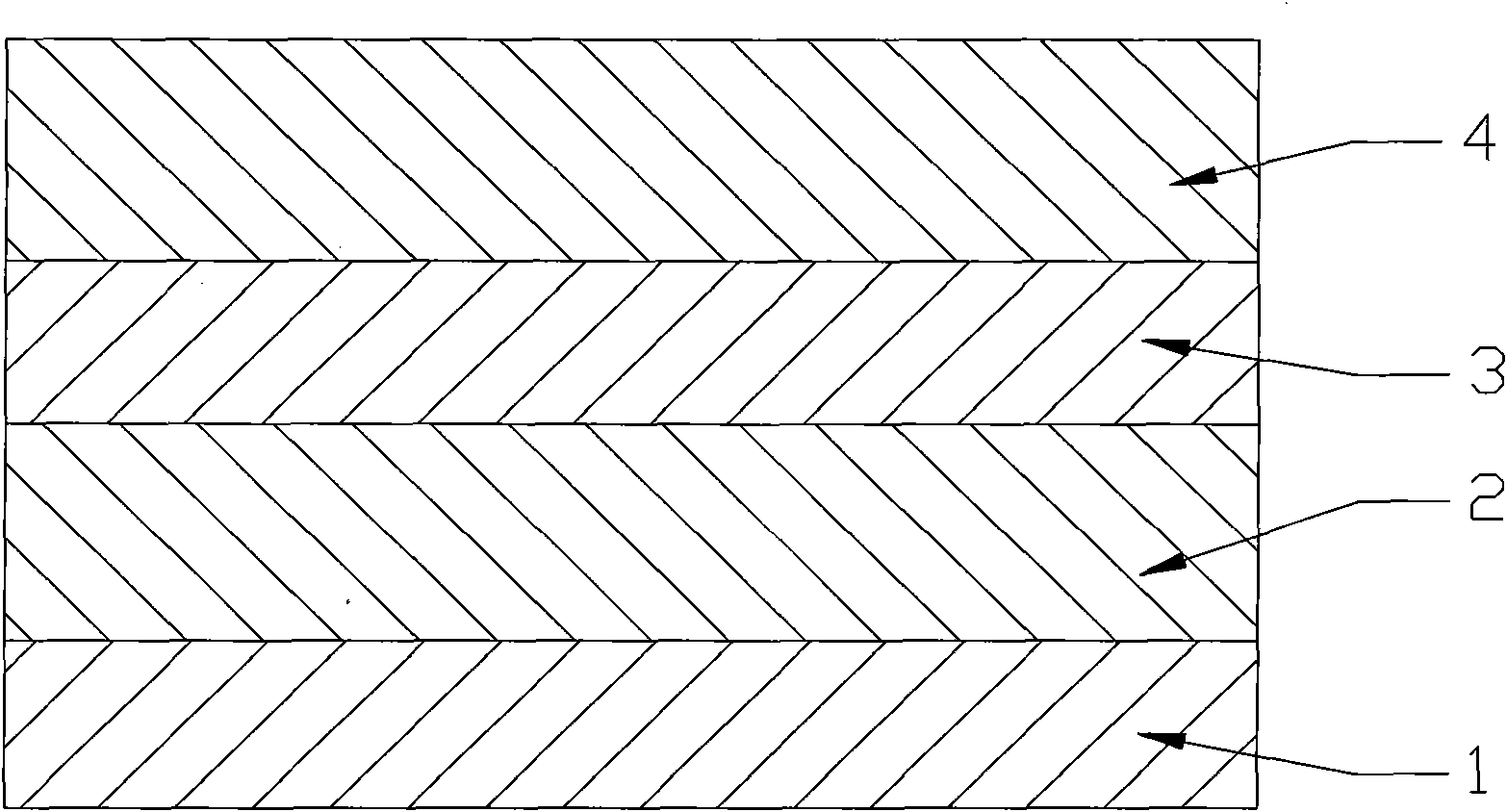

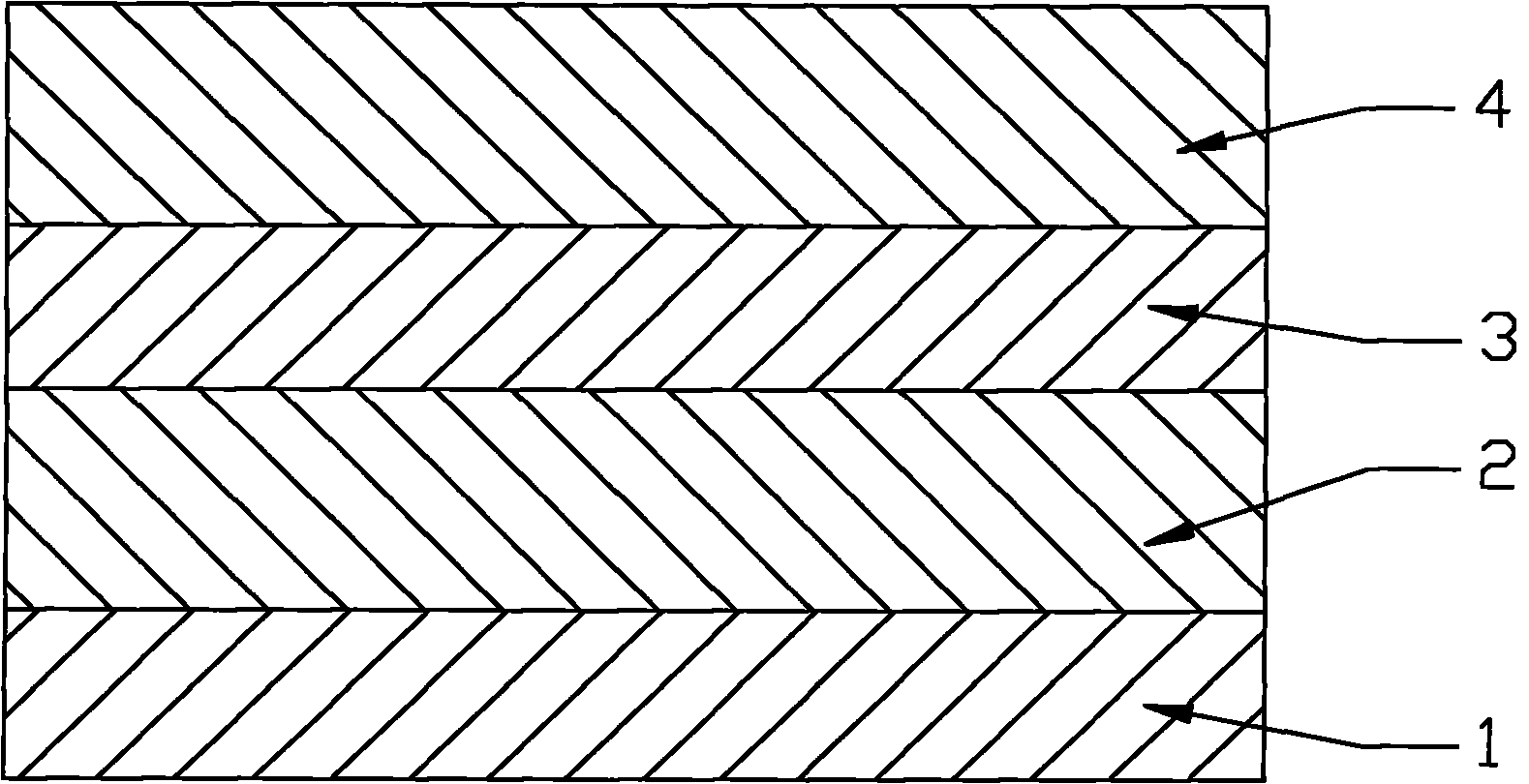

[0011] like figure 1 As shown, the embodiment of the present invention is composed of a non-woven paper base layer 1 , a water-based acrylic emulsion adhesive layer (adhesive layer) 2 , a metal foil layer 3 and a water-based acrylic layer (protective layer) 4 from bottom to top. The water-based acrylic emulsion penetrates into the base layer of the non-woven paper to release water, seal the back and not harden, and improve the smoothness. The water-based acrylic emulsion adhesive layer can also play the effect of sticking metal foil, which enhances the adhesion of the adhesive layer and reduces the surface scratches caused by the foil sticking process. In the base layer, the base layer is hard and the foil is not firm. The metal foil can be pure gold foil, silver foil, copper foil, aluminum foil or other metal foil. Water-based acrylic layer to pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com