Glue clearing equipment for display screen

A display screen and glue removal technology, which is applied in cleaning methods and utensils, chemical instruments and methods, etc., can solve problems such as high labor cost, high defect rate, and scratches on the display screen surface, so as to reduce labor costs and reduce surface scratches. The rate of damage or deformation defects, and the effect of improving glue removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

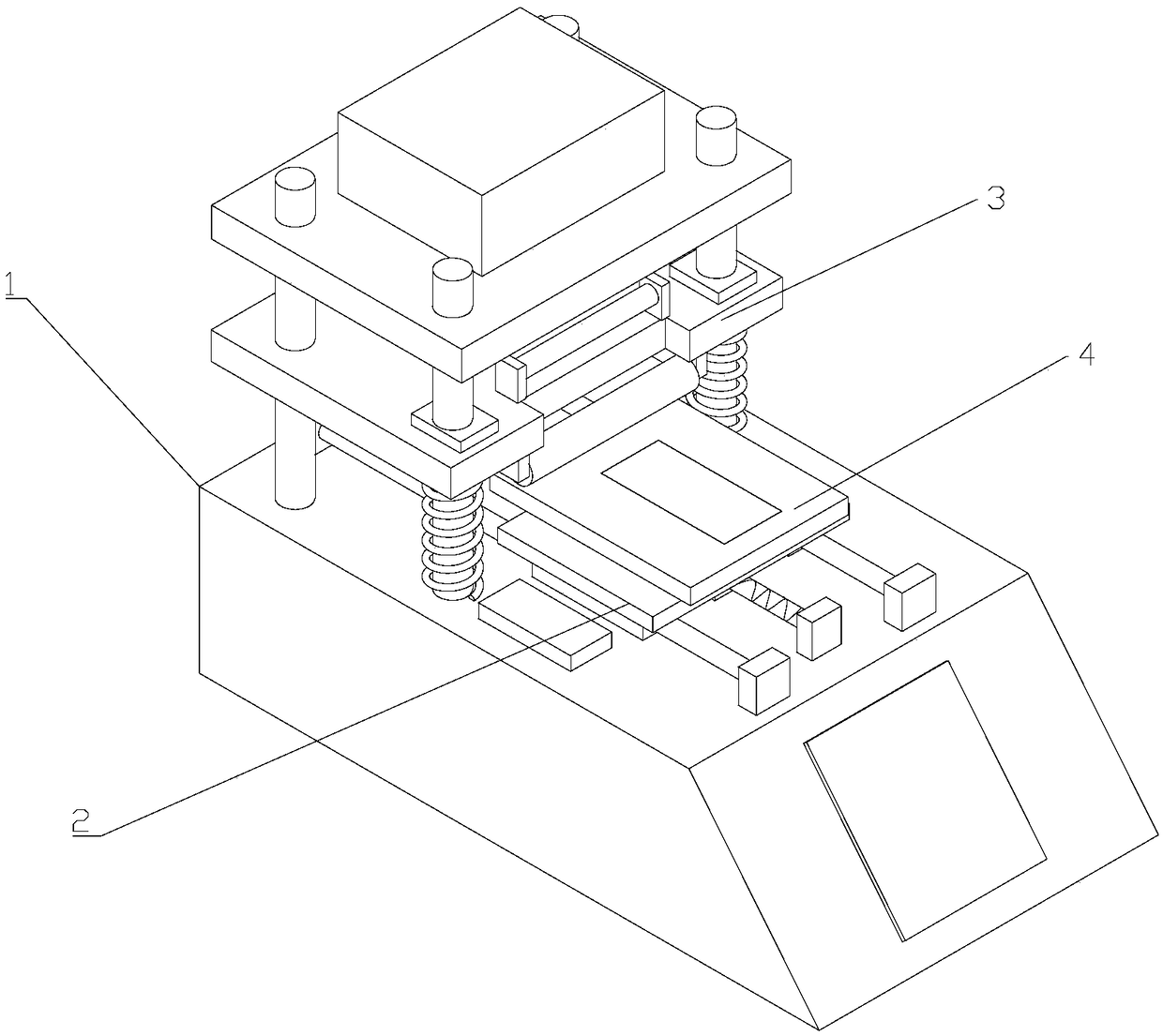

[0042] Please refer to Figure 1-Figure 2 , Embodiment 1 of the present invention is:

[0043] A glue clearing device for a display screen, comprising a frame 1 and a fixing assembly 2 and a glue clearing assembly 3 respectively arranged on the frame; the glue clearing assembly 3 is located above the fixing assembly 2;

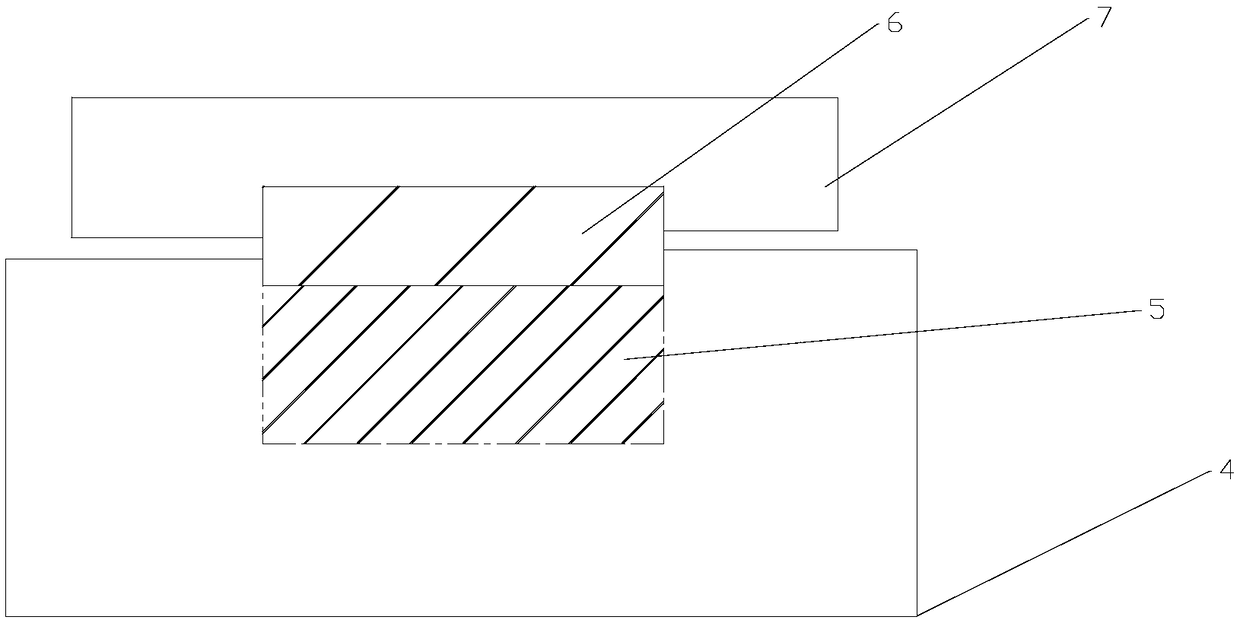

[0044] The fixing assembly 2 includes a fixing plate 4, the upper surface of the fixing plate 4 is provided with a groove 5 adapted to the display screen, specifically, the cross-sectional shape of the groove 5 is rectangular, and the upper surface of the fixing plate That is, towards the side of the glue removal assembly, the surface of the display screen has an adhesive layer 6 to be removed; the glue removal assembly 3 includes a roller 7, and the groove depth of the groove 5 is configured so that the display screen is located in the groove When the level of the notch edge of the groove is located in the adhesive layer of the display screen, the notch edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com