Continuous automatic glue spraying machine for carbon felt

A technology of automatic glue spraying machine and carbon felt, which is applied in the continuous processing of textile materials, processing of textile materials, accessories of textile processing machines, etc., can solve problems such as affecting product quality, achieve mechanization and automation, and simple operation and maintenance. , the effect of improving wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

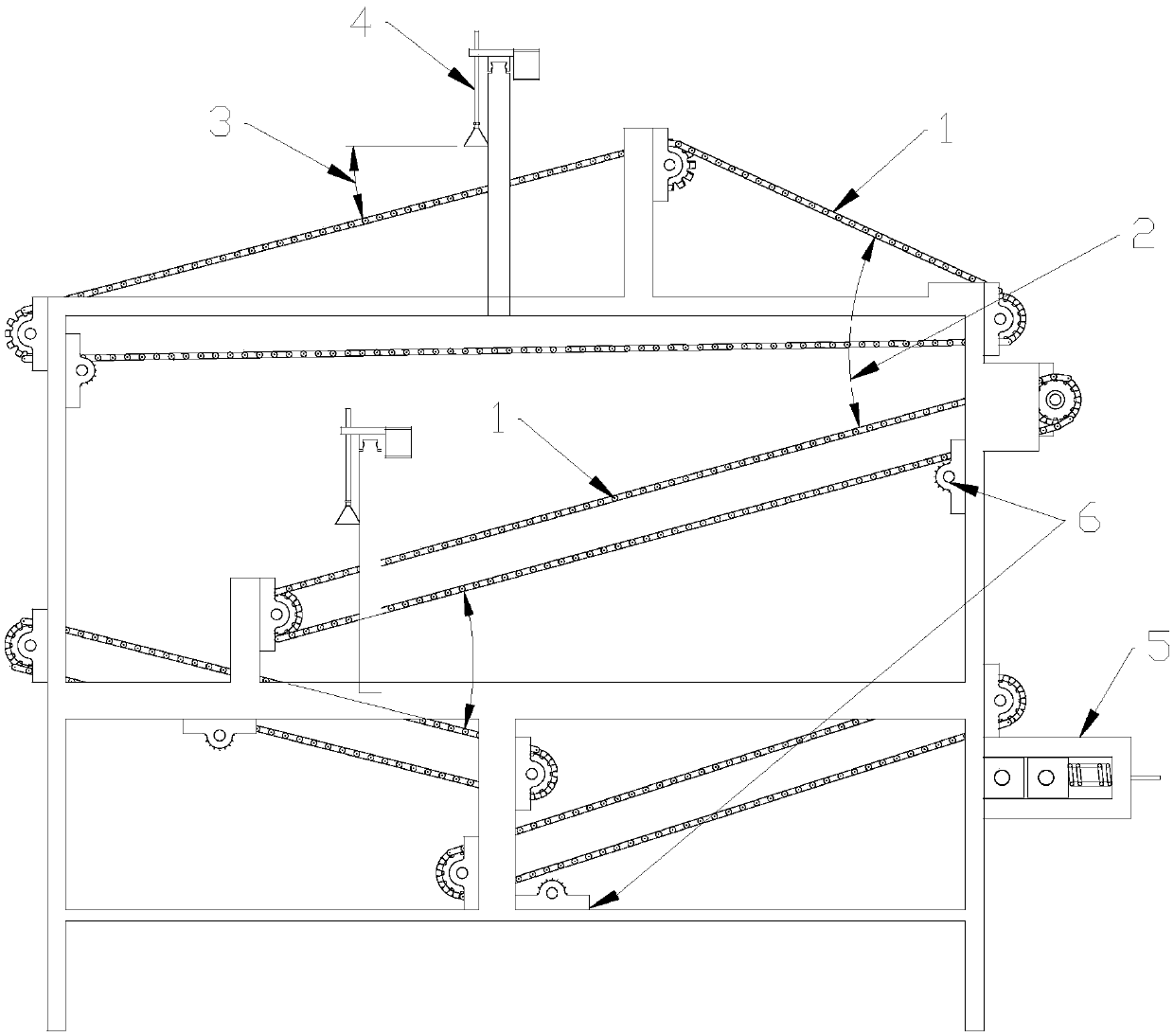

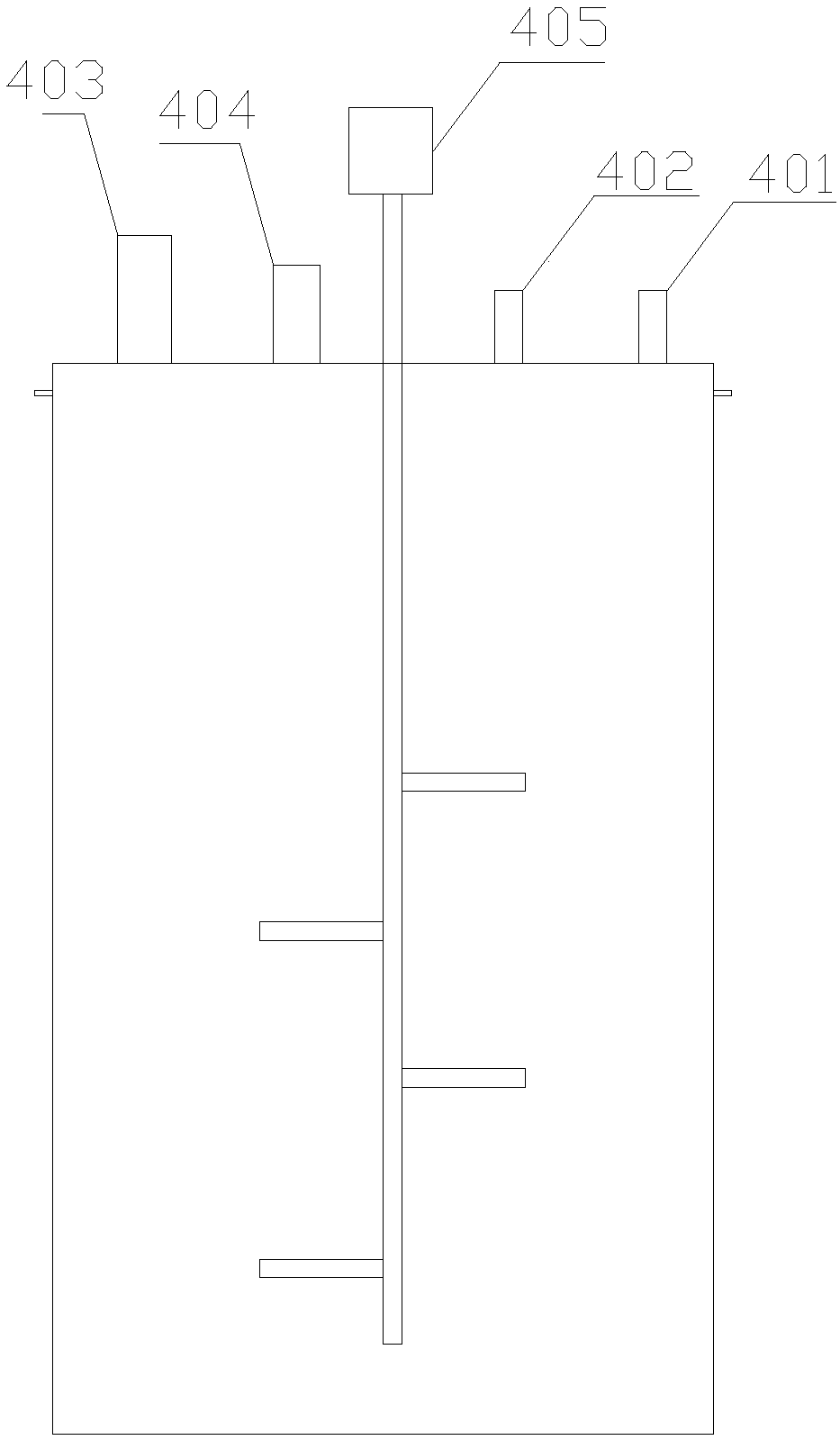

[0024] A continuous automatic glue spraying machine for carbon felt, such as figure 1 As shown, it includes a felt turning mechanism 1, a felt turning mechanism 2, a carbon felt soaking mechanism 3, a glue spraying mechanism 4, a carbon felt extrusion mechanism 5, a mesh belt cleaning mechanism 6 and a frame; the frame is a rectangular structure , and the frame is provided with several transport units, the two ends of the frame of the transport unit are provided with gear transport sticks, and the upper part is provided with an inverted U-shaped glue spray support frame and gear transport rollers, and the glue spray support frame Glue spraying mechanism 4 is installed on it, and several mesh belts form the transport rollers, and the mesh belts are connected with the gear transport rollers at both ends of the frame and the transport rollers above to form a closed structure through chains; the transport frame at the lowermost end The outer side is provided with a carbon felt ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com