Chopstick sorting device

A technology of chopsticks and equipment, applied in the field of chopsticks sorting equipment, can solve problems such as low efficiency of manual operations, and achieve the effect of promoting practical significance, improving sorting efficiency, and realizing mechanization and automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The device of the present invention will be further described below in conjunction with a specific embodiment.

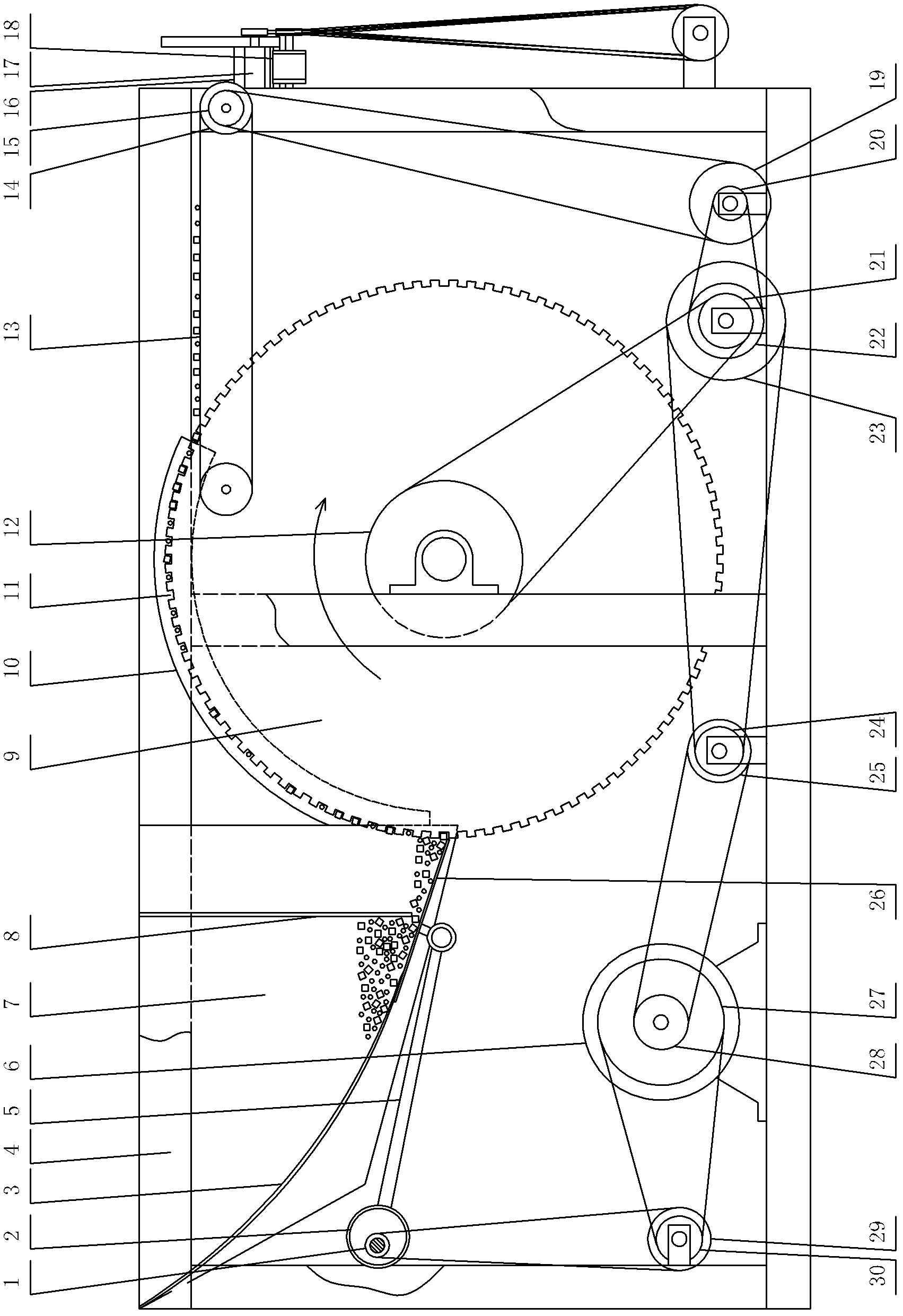

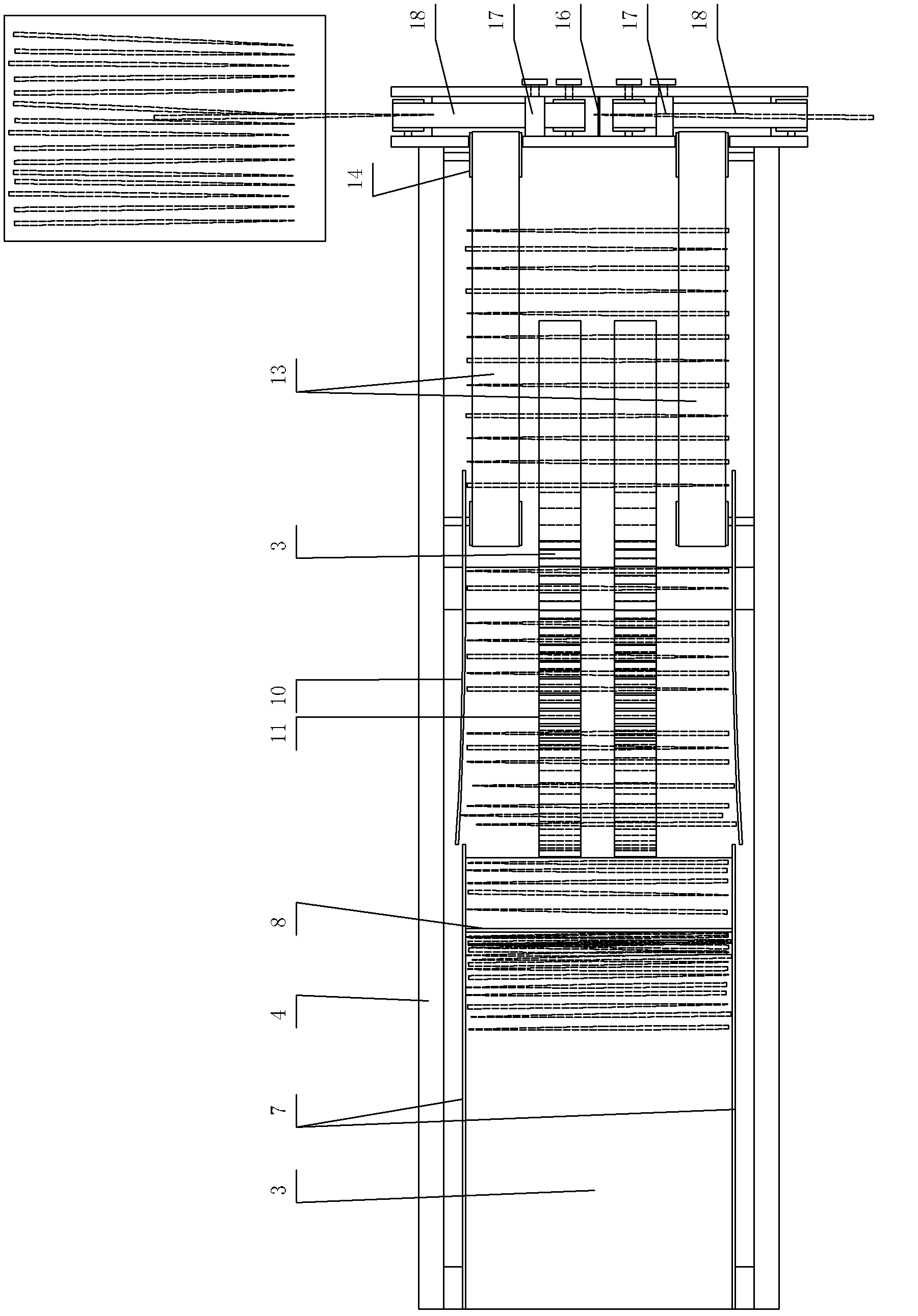

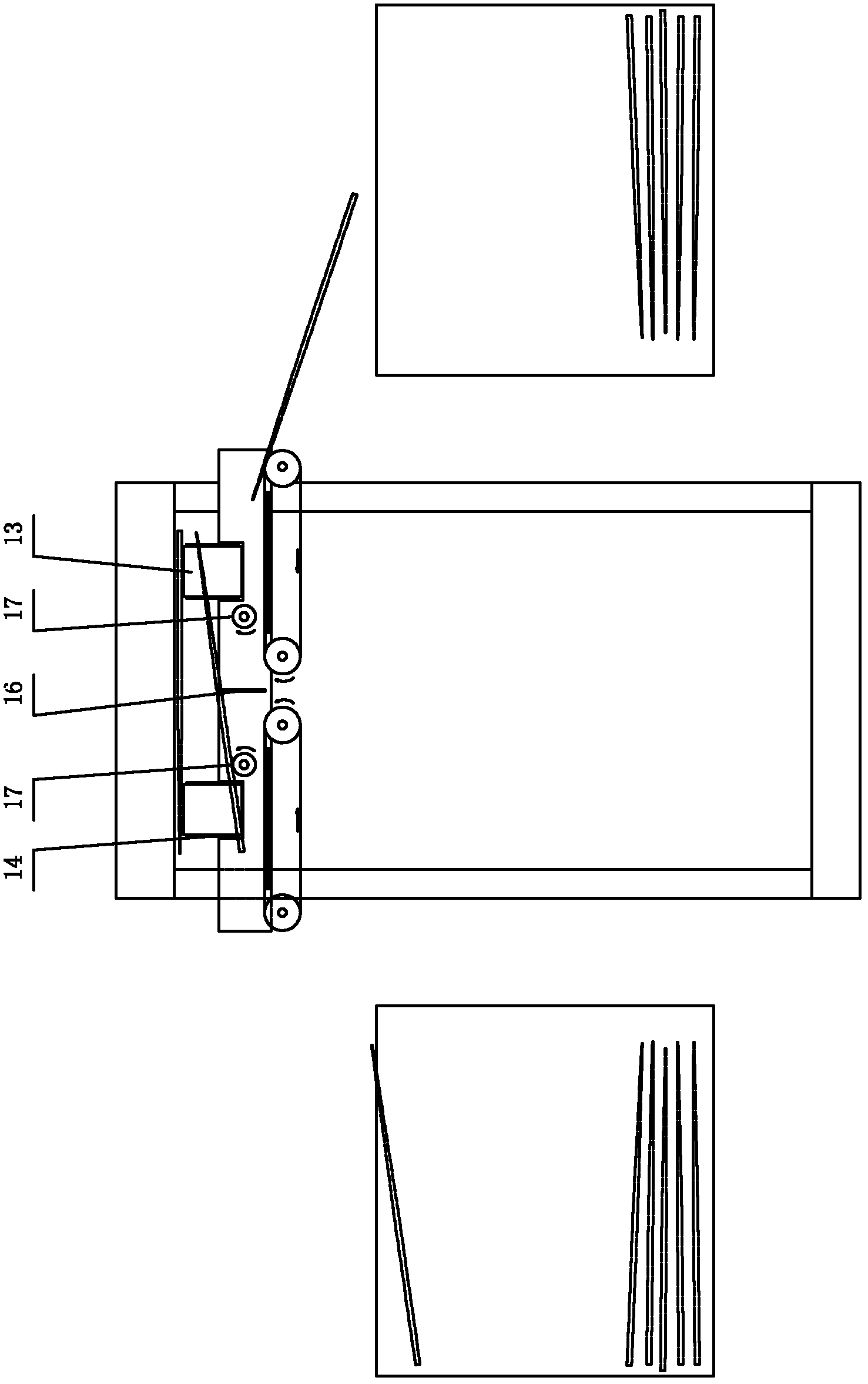

[0021] refer to figure 1 , in this example, the chopsticks sorting device mainly includes a frame 4, and a chopstick bucket arranged on the frame, a transmission mechanism, a sorting mechanism, and a power system.

[0022] Described chopstick bucket is made up of base plate, left and right side plate 7, front baffle plate 8. The front baffle 8 is arranged vertically, and the gap left between its bottom edge and the bottom plate constitutes a chopstick outlet; the left and right side plates 7 are parallel and symmetrically arranged, and the distance is slightly greater than the length of a chopstick; The rear part 3 is an arc-shaped plate, its two sides are welded and fixed to the left and right side plates 7, its rear side is bent upwards and extended to be fixed with the top beam of the frame, the height is equal to the top of the left and right side pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com