Sunflower seed length sorting combined type special-shaped nest hole mechanism

A sunflower seed and combined technology, applied in the field of sunflower seed sorting mechanism, can solve problems such as instability, poor filling effect of sunflower seeds, poor sorting quality, etc., and achieve novel structure, high sorting efficiency and good quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

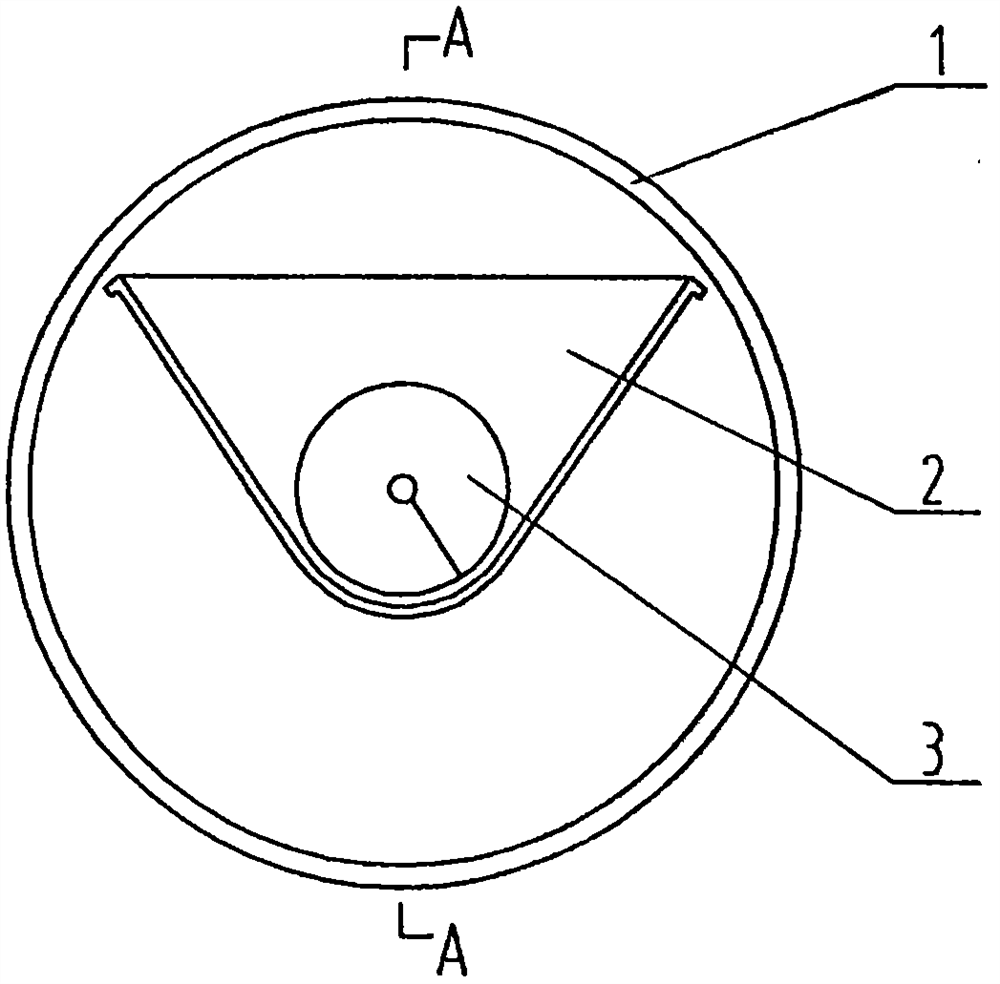

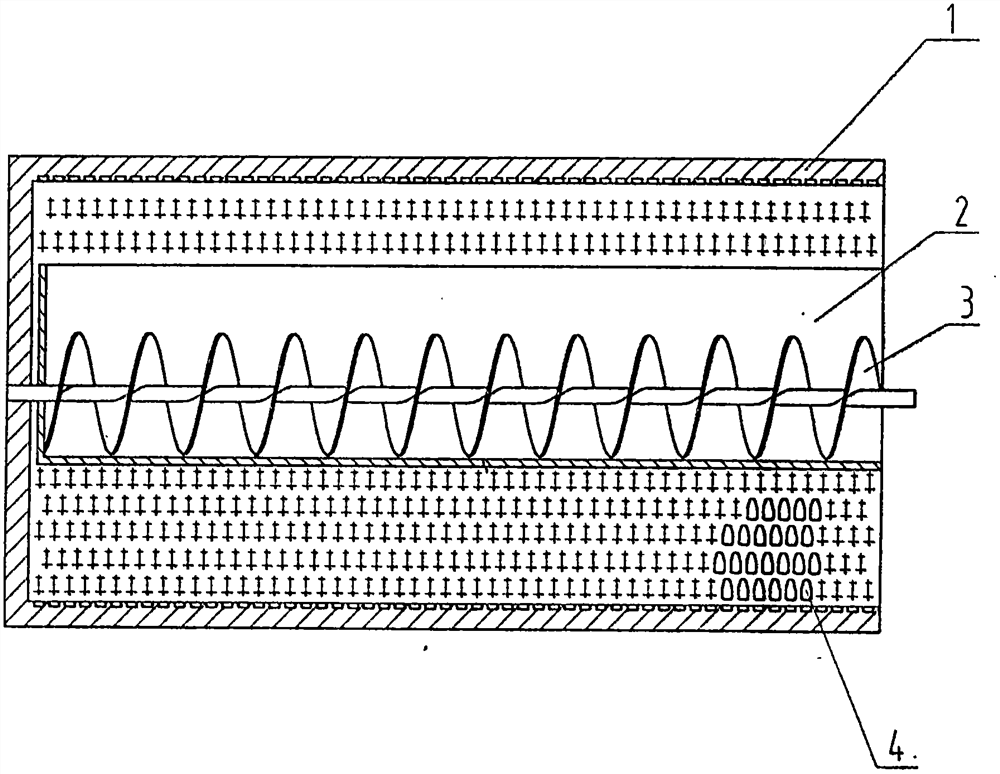

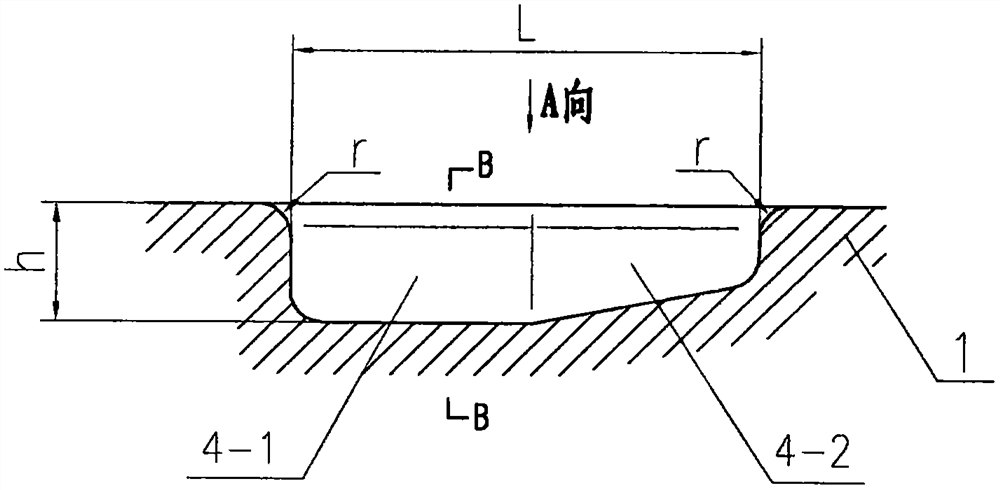

[0013] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. A sunflower seed length sorting combined special-shaped socket mechanism, the sorted sunflower seed collecting tank 2 is fixedly arranged in the cavity of the rotating sorting drum 1, and the sorted sunflower seed collecting tank 2 can be The spiral blade conveying auger assembly 3 is rotatably equipped, and N combined special-shaped sockets 4 are uniformly arranged on the inner wall surface of the cylinder cavity of the sorting drum 1; the combined special-shaped sockets 4 are composed of rectangular sockets 4 -1 and the conical socket 4-2 are connected to each other, and a circular arc with a radius r is provided at the transition connection between the rectangular socket 4-1, the tapered socket 4-2 and the inner wall of the sorting drum 1 , the taper end of the tapered socket 4-2 is an arc of radius R, and the vertical wall surfaces on opposite sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com