Beneficiation reagent for tin flotation of tin ore and preparation method of beneficiation reagent

A beneficiation agent and tin flotation technology, applied in flotation, solid separation, etc., can solve the problems of waste of mineral resources, low recovery rate of tin concentrate, and the result cannot meet the design requirements, and achieve high yield and easy operation , The effect of high sorting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

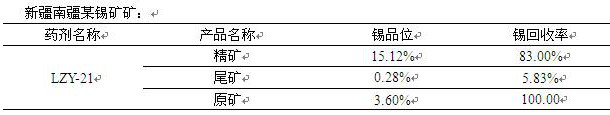

[0019] Example 1, a kind of beneficiation agent for tin ore flotation, made of the following raw materials in parts by weight: 20-30 alkyl phosphate, 20-25 sodium carbonate, 20-30 sodium phosphide, 3,3-di Methyl butyric acid 35-45, phosphorus 15-23, hydroxybutyl ethylene 10-25, 3-amino-2-butenoic acid 35-50, quicklime 4-5, activator 12-15. Example 1 was applied to the flotation of a tin ore in southern Xinjiang, and the beneficiation reagent was named LZY-21, and the indicators were as follows:

[0020]

Embodiment 2

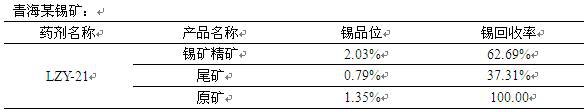

[0021] Example 2, a kind of beneficiation reagent for tin ore flotation, made of the following raw materials in parts by weight: 20-30 alkyl phosphate, 20-25 sodium carbonate, 20-30 sodium phosphide, 3,3-di Methyl butyric acid 35-45, phosphorus 15-23, hydroxybutyl ethylene 10-25, 3-amino-2-butenoic acid 35-50, quicklime 4-5, activator 12-15. Embodiment 2 is applied to the flotation of a certain tin ore in Yunnan, and the beneficiation agent is named LZY-21, and the indicators are as follows:

[0022]

Embodiment 3

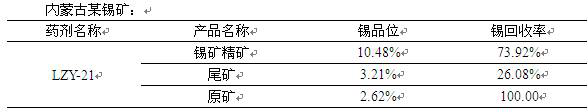

[0023] Example 3, a kind of beneficiation agent for tin ore flotation, made of the following raw materials in parts by weight: 20-30 alkyl phosphate, 20-25 sodium carbonate, 20-30 sodium phosphide, 3,3-di Methyl butyric acid 35-45, phosphorus 15-23, hydroxybutyl ethylene 10-25, 3-amino-2-butenoic acid 35-50, quicklime 4-5, activator 12-15. Embodiment 3 is applied to the flotation of a tin mine in Inner Mongolia, and the beneficiation agent is named LZY-21, and the indicators are as follows:

[0024]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com