Speaker dust cap glue removal device

A technology for dustproof caps and loudspeakers, which is applied to sensors, electrical components, etc., can solve the problems of time-consuming and laborious installation of dustproof caps, increase the labor intensity of operators, and increase the cost of enterprises, so as to reduce the rework rate of products and the production cost of enterprises , simple structure, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

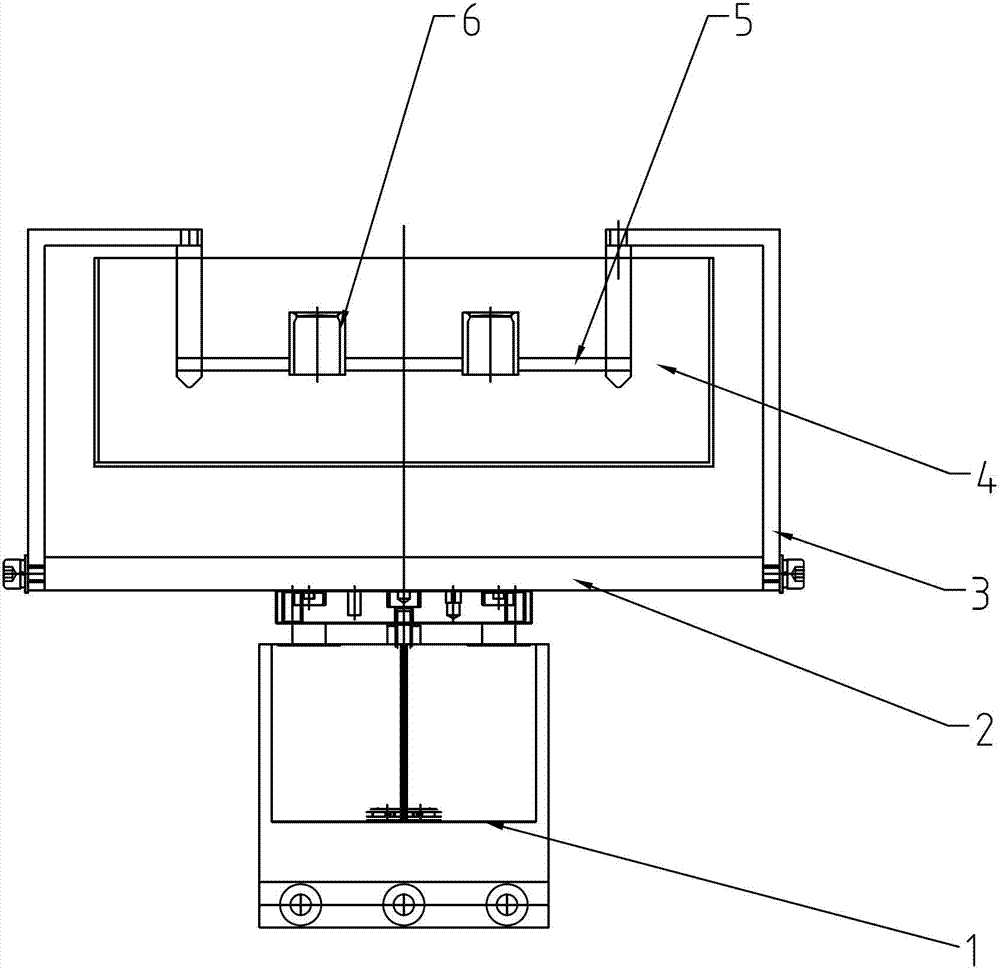

[0012] Such as figure 1 As shown, the present invention mainly comprises getting the lower bracket 2, getting the upper bracket 3 and getting the inner bracket 5. Bracket 5.

[0013] The glue box 4 is positioned at the bottom of the upper bracket 3 for getting glue, and the inner bracket 5 for getting glue is positioned in the glue box 4. A plurality of upper rubber rings 6 are arranged on the inner bracket 5 for taking glue. There are two upper aprons 6 in the present embodiment.

[0014] The lower bracket 2 for taking glue is pushed up and down by the piston rod of the glue taking cylinder 1 .

[0015] The specific working process of the present invention is as follows: when the workpiece needs to be dipped in glue, the piston rod of the glue cylinder 1 pushes the lower bracket 2 to move downward, and the lower bracket 2 drives the upper bracket ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com