Lead-free halogen-free tinol and preparation process

A solder paste and halogen technology, applied in the field of lead-free and halogen-free solder paste and its preparation, can solve the problems of destroying the earth's ecological environment, endangering human health, polluting water sources, etc., achieving no short-circuit defects, good compatibility, soldering Less post-residue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

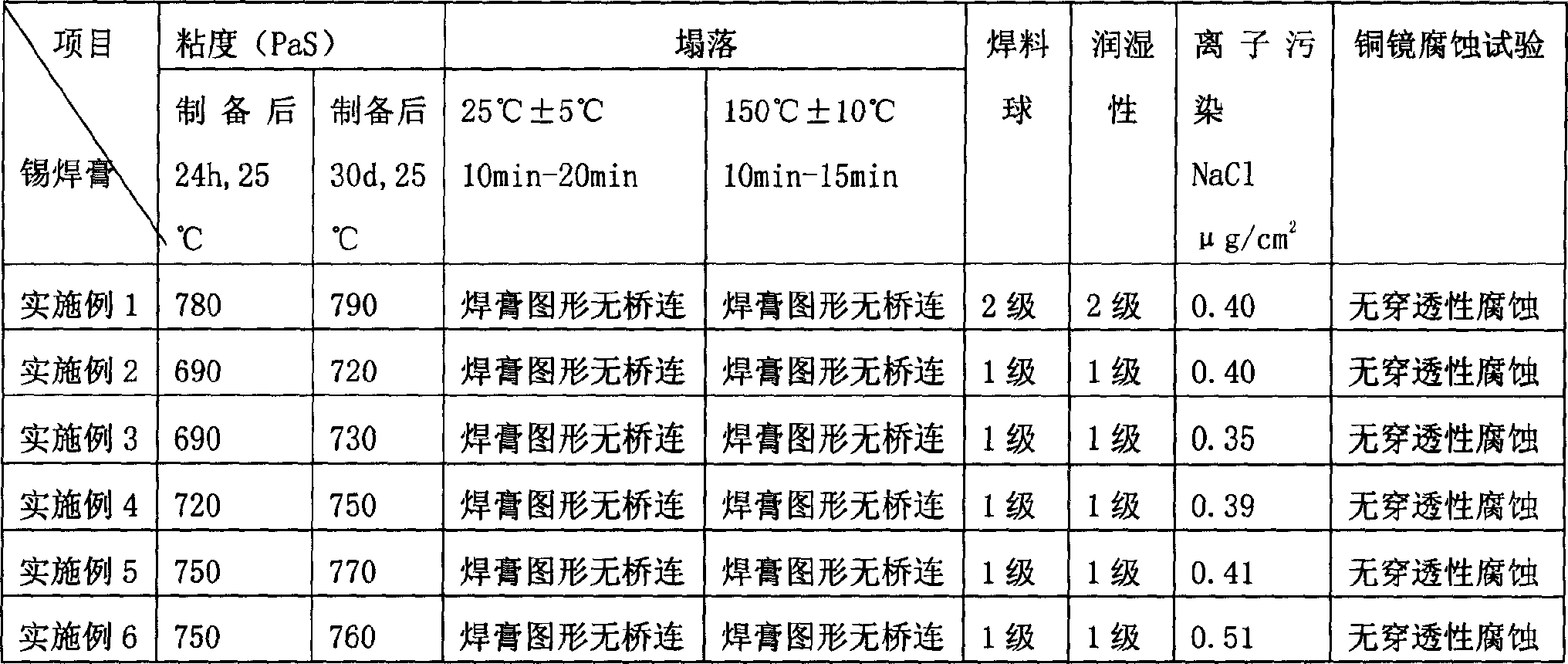

Examples

Embodiment 1

[0027] Preparation of modified resin antioxidant (1)

[0028] Raw material (g): Modified rosin resin 80g (prepared from the following raw materials in weight ratio: polymerized rosin, water white rosin, hydrogenated rosin or acrylic rosin, ratio 47:40:2), antioxidant 2g (from the following Preparation of raw materials in weight ratio: tetra[β-3,5-di-tert-butyl 4-hydroxy-phenyl] propionate butanepentaerythritol, 1,3,5-trimethyl-2,4,6- Tris(3,5-tert-butyl-4hydroxybenzyl)benzene, 1,1,3-tris(2-methyl-4-hydroxy-5-tert-butylphenyl)butane, ratio 1:1: 1) The reducing agent 5g is cis-9-octadecenoic acid.

[0029] Preparation method: accurately weigh each raw material according to the ratio, put the polymerized rosin, water white rosin, and acrylic rosin into a glass-lined or enamel kettle to be completely melted, then start the stirrer for low-speed stirring at a stirring speed of 40-60 Turn / min, add antioxidant and reducing agent in sequence under stirring until all are melted and mixed i...

Embodiment 2

[0037] Preparation of flux (1)

[0038] Raw material (g): modified resin antioxidant 40 of one of Example 1, suberic acid 1, malic acid 2, tartaric acid 3, dodecanoic acid 6, monoglyceride 4, hydrogenated rosin methyl ester 3.5, Ceresin 0.5, benzotriazole 0.2, triethylene glycol ether 16, propylene glycol 23.8.

[0039] Preparation method: accurately weigh various raw materials according to the formula ratio, put the modified resin antioxidant in a glass-lined or enamel kettle, add some organic solvents and stir at room temperature until all are dissolved, the stirring speed is 40-60 rpm . In another glass-lined or enamel kettle, add the remaining solvent, add thixotropic agent, plasticizer, forming agent, corrosion inhibitor in sequence while heating to 90-100°C, and stir until all are dissolved. Add the organic acid activator when the temperature is lowered to 70-80°C, and stir until all are dissolved uniformly, and naturally fall to room temperature. The modified resin antioxid...

Embodiment 3

[0059] Preparation of lead-free and halogen-free solder paste (1)

[0060] Raw material (g): 90g of Sn3.0Ag0.5Cu alloy powder, 10g of one of the fluxes of Example 2.

[0061] Preparation method: Put the soldering flux and alloy powder into a stainless steel mixing kettle, evacuate, the vacuum degree is -0.06--0.04MPa, start the stirrer and stir for 30-40min, then the finished solder paste will be obtained.

[0062] Preparation of lead-free and halogen-free solder paste (2)

[0063] Raw material (g): 91 g of Sn3Ag1.2Ni alloy powder, 9 g of one of the fluxes of Example 2.

[0064] Preparation method: Put the soldering flux and alloy powder into a stainless steel mixing kettle, evacuate, and the vacuum degree is -0.06MPa, start the stirrer for stirring for 20 minutes, and then the tin solder paste is finished.

[0065] Preparation of lead-free and halogen-free solder paste for SMT (3)

[0066] Raw material (g): 88g of Sn4Ag6Bi0.18Cu alloy powder, 12g of one of the fluxes of Example 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com