Device for gas displacement of working chambers of oven and sintering furnace

A technology of gas replacement and working room, which is applied in the direction of dry gas arrangement, maintenance of heating chamber, furnace, etc. It can solve the problems of increased manufacturing cost, long time required, high overall rigidity and sealing requirements, and achieve reduced manufacturing cost, Not demanding, overcome the effect of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific structure and working method steps of the present invention will be described in detail below in conjunction with the oven of the ventilation device of the present invention, so as to better understand the present invention.

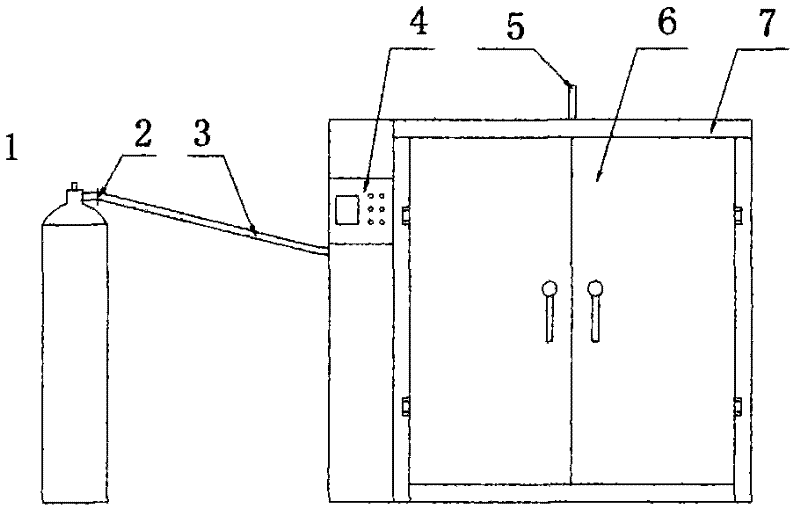

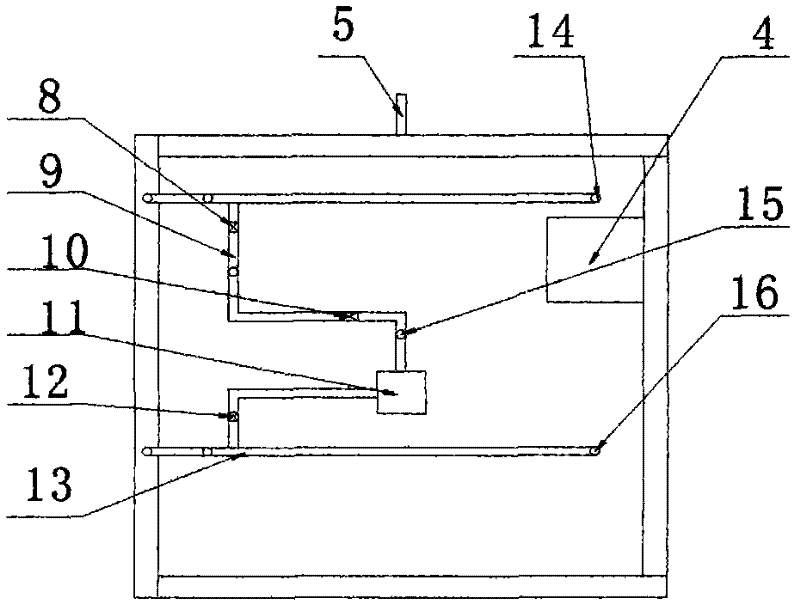

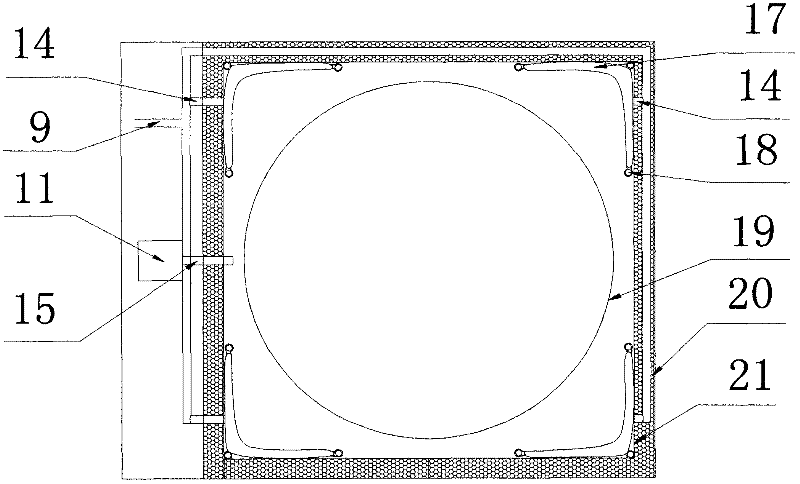

[0017] as attached figure 1 , 2 , 3, the oven of the ventilator disclosed in the present invention comprises casing 7, working chamber 21, air bag 17, air pump 11, controller 4 and components such as heating assembly.

[0018] Described box body 7 has box door 6, and the sealing between box body 7 and box door 6 does not have strict requirement compared with vacuum oven, and box body 7 material can be stainless steel plate, galvanized steel plate or spray-painted steel plate, and box body 7 The shape and size are non-restrictive, and can be designed and adjusted according to the requirements and conditions of use.

[0019] Working room 21 is positioned at casing 7 insides, is arranged near box door 6, and working room 21 is position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com