1800MPa-level plating-free thermoforming steel with low high-temperature friction coefficient and preparation method of 1800MPa-level plating-free thermoforming steel

A hot forming steel and friction coefficient technology, applied in the field of metallurgy, can solve the problems affecting the profile size and surface quality, unfavorable cold bending performance of parts, unfavorable plastic toughness of parts, etc., so as to improve the hot forming stamping environment, make the process easier to control, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0094] A method for preparing 1800MPa grade uncoated hot-formed steel with low high-temperature friction coefficient, the steps are:

[0095] 1) Steelmaking production

[0096] Based on the role of mold slag in the steelmaking process (1. to isolate molten steel from the air; 2. to lubricate during continuous casting), for 1800MPa grade hot forming steel, due to the difference in composition, high-carbon mold slag is preferred.

[0097] 2) Continuous casting + hot rolling production

[0098] The casting slab is preferentially organized in the way of hot charging, on the one hand, in order to improve the production tempo, and on the other hand, in order to reduce the risk of cracks in the casting slab; Enter the heat preservation pit for slow cooling treatment. The purpose of slow cooling treatment is twofold. One is to reduce the risk of cracks, and the other is to slowly cool and expand hydrogen to reduce the hydrogen content inside the slab.

[0099] Furnace temperature: 1...

Embodiment 1

[0132] In this embodiment, the surface roughness Ra is 2.0 μm, and the average high temperature friction coefficient is 0.76.

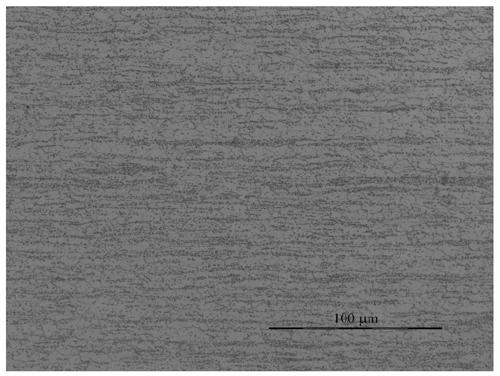

[0133] The surface morphology of the steel strip is as Figure 5 , Figure 6 As shown, the high temperature friction coefficient of the strip is as Figure 11 shown.

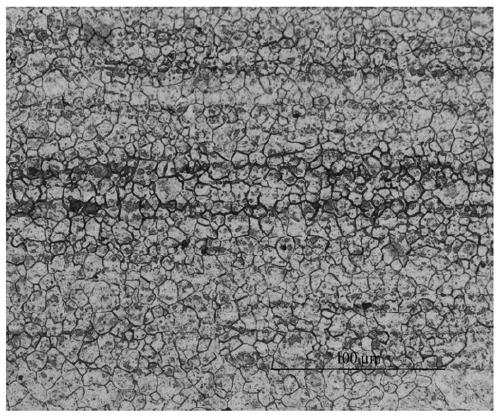

[0134] like Figure 14 As shown, there is a thicker oxide layer on the surface of the part.

Embodiment 2

[0136] In this embodiment, the surface roughness Ra is 0.8 μm, and the average high temperature friction coefficient is 0.64.

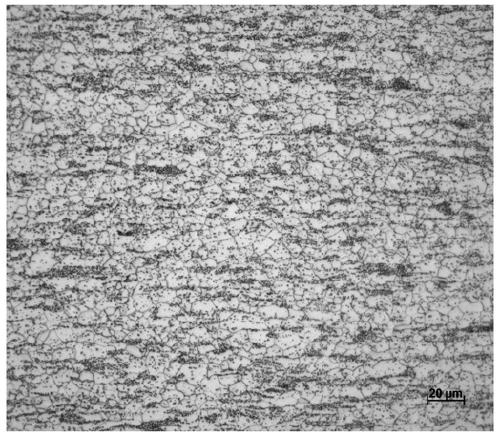

[0137] The surface morphology of the steel strip is as Figure 7 , Figure 8 As shown, the high temperature friction coefficient of the strip is as Figure 12 shown.

[0138] like Figure 16 As shown, there is no obvious oxide layer on the surface of the part, but there is a slight carbonization of anti-rust oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com