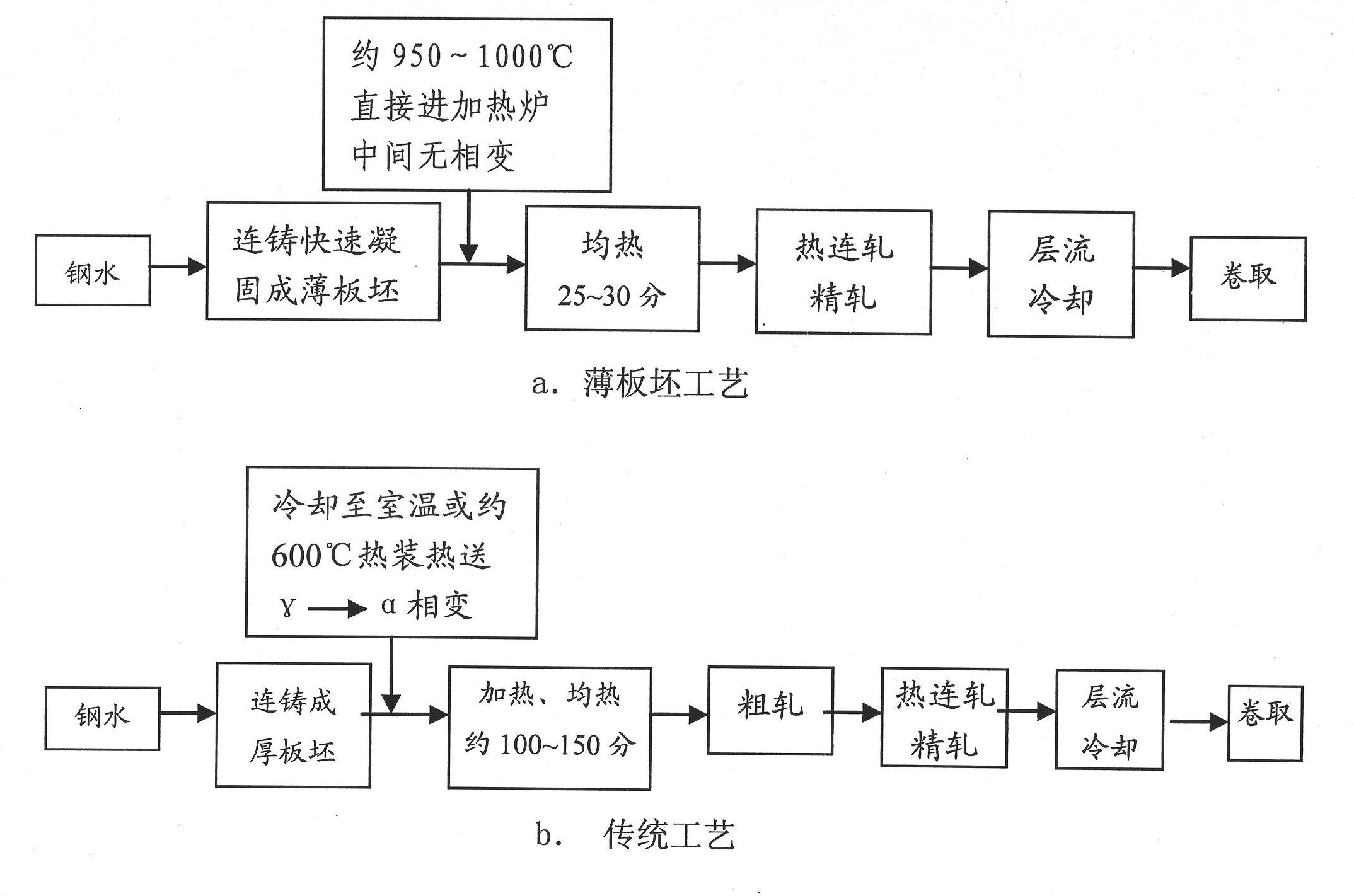

Method for producing extra-deep drawing cold-rolled steel plate based on ASP process

A technology of cold-rolled steel sheets and ultra-deep drawing grades, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve problems such as cold-rolled steel sheets that have not yet been used, and achieve widening the range of product varieties, low production costs, and improving product quality. The effect of competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 of the present invention comprises the following steps successively:

[0029] (1) Hot metal pretreatment: use the KR method for hot metal pretreatment for deep desulfurization, and control the sulfur content of the molten iron into the furnace below 0.003% (wt / wt) after slag removal;

[0030] Steelmaking: The steelmaking furnace adopts a 120-ton converter, the tapping volume is 148.61 tons, the weight percentage of carbon is 0.0469% when tapping, and the tapping temperature is 1644°C;

[0031] The molten steel from the converter is deoxidized and slagged and temperature controlled in the LF refining furnace. The specific process: the treatment cycle is 61 minutes, the heating time is 34 minutes, the arrival temperature is 1563°C, the exit temperature is 1642°C, and the compressed air flow rate is 300m 3 , Feed 120kg of aluminum pellets.

[0032] The molten steel from the steelmaking furnace is refined in the RH furnace, and the alloy composition is adjuste...

Embodiment 2

[0051] Embodiment 2 of the present invention comprises the following steps successively:

[0052] (1) Hot metal pretreatment: use the KR method for hot metal pretreatment for deep desulfurization, and control the sulfur content of the molten iron into the furnace below 0.003% (wt / wt) after slag removal;

[0053] Steelmaking: The steelmaking furnace adopts a 120-ton converter, the tapping volume is 144.5 tons, the weight percentage of carbon is 0.0497% when tapping, and the tapping temperature is 1631°C;

[0054] The molten steel from the converter is deoxidized and slagged and temperature controlled in the LF refining furnace. The specific process: the treatment cycle is 52 minutes, the heating time is 24 minutes, the arrival temperature is 1554°C, the exit temperature is 1648°C, and the compressed air flow rate is 100m 3 , Feed 110kg of aluminum pellets.

[0055] The molten steel from the steelmaking furnace is refined in the RH furnace, and the alloy composition is adjusted...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com